2025 Comprehensive Guide to Ceramic Honeycomb

1. Introduction

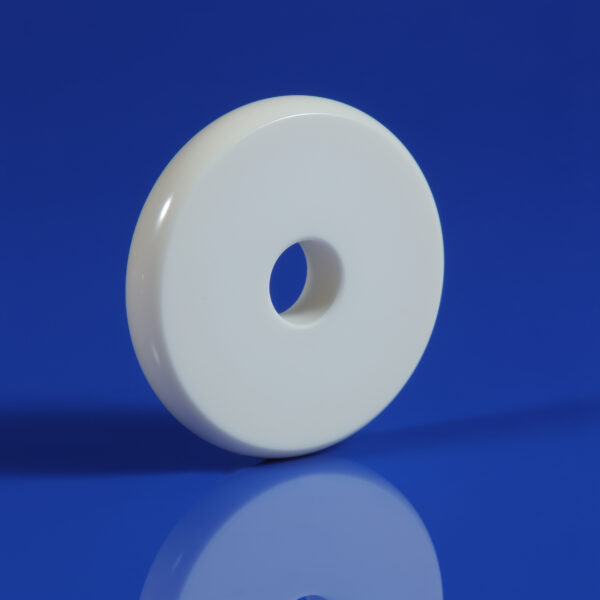

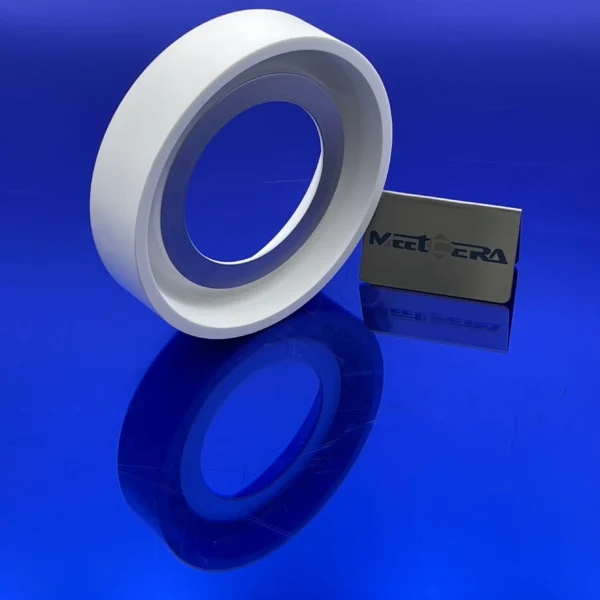

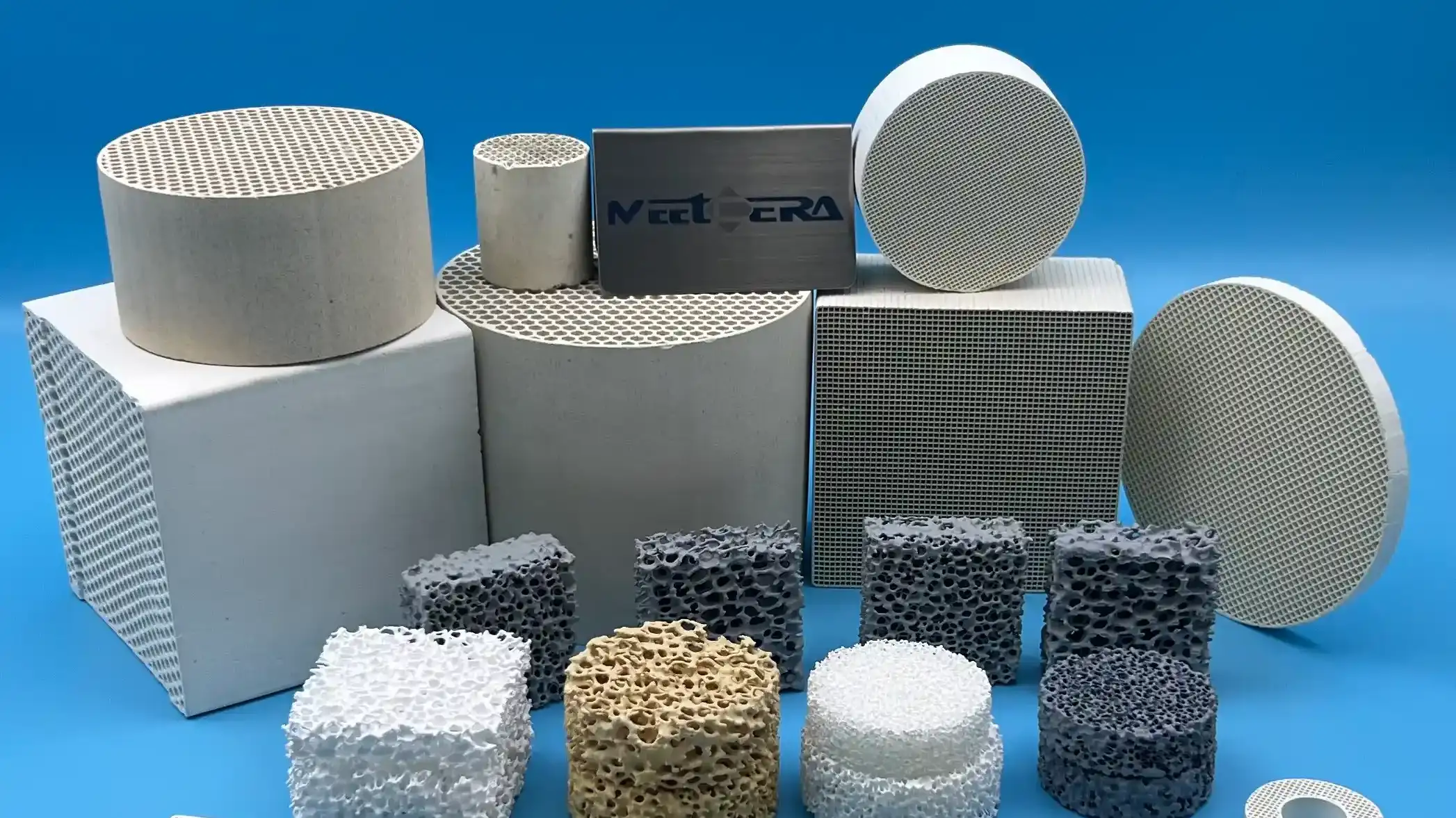

Ceramic honeycomb is an advanced biomimetic engineering material with a unique structure that mimics the natural beehive, consisting of numerous regularly arranged hexagonal (or square) thin-walled channels. This porous design makes it excel in fields such as catalysis, filtration, heat exchange, and thermal insulation1, serving as a core component in modern environmental protection and industrial technologies.

(1)Why is it called honeycomb?

The name comes from its appearance and structure, which closely resemble the hexagonal grid of a beehive. This natural design achieves the optimal balance of minimal material usage, maximum surface area, and superior strength.

(2)Difference from real honeycomb

- Real honeycomb: Made from beeswax secreted by honeybees; stores honey, pollen, and larvae; edible and biological.

- Ceramic honeycomb: Synthetic inorganic material, primarily composed of compounds like cordierite; not edible; designed for high-temperature and corrosion-resistant industrial environments.

2. Structure and Properties of Ceramic Honeycomb

The core of ceramic honeycomb lies in its unique porous structure2: thin-walled grids form numerous parallel channels, providing high specific surface area, excellent permeability, and mechanical strength while maintaining low density.

(1)Key performance features

- High strength with low density: Excellent strength-to-weight ratio for lightweight applications.

- Outstanding thermal stability: Can withstand temperatures above 1400°C with low thermal conductivity.

- High specific surface area and permeability: Ideal for catalytic reactions and fluid flow.

- Strong corrosion resistance: Resists harsh chemical environments.

(2)The three main types of ceramics

Traditional ceramics:

- Earthenware: Low-fired, porous

- Stoneware: Medium-fired, dense

- Porcelain: High-fired, vitrified, often translucent

Ceramic honeycomb belongs to advanced engineering ceramics, commonly using:

- Oxide ceramics: Cordierite, alumina

- Carbides: Silicon carbide

- Nitrides

3. Applications and Advantages of Ceramic Honeycomb

(1)Primary application areas

- Automotive exhaust purification: Core substrate for three-way catalytic converters3 and particulate filters (DPF/GPF)4, reducing CO, HC, NOx, and particulate emissions.

- Industrial waste gas treatment: VOC abatement, regenerative thermal oxidizers (RTO), particulate filtration.

- Thermal insulation and energy: Furnace linings, aerospace components, thermal management in new energy batteries.

- Others: Chemical catalysis, molten metal filtration, etc.

(2)Are honeycomb filters good?

Yes—extremely effective. Ceramic honeycomb filters offer high efficiency, high-temperature resistance, corrosion resistance, and long service life, making them the gold standard for automotive and industrial emission control. They help vehicles meet Euro VI and China VII standards.

(3)Is ceramic honeycomb worth the investment?

Absolutely. With tightening global emission regulations and growing demand for thermal management in new energy vehicles, the ceramic honeycomb market is projected to grow at a compound annual rate of 6–8% in 2025. Its long lifespan and energy-saving properties deliver significant returns.

4. Disadvantages of Ceramic Honeycomb

Despite its advantages, ceramic honeycomb has certain limitations:

- High brittleness: Prone to fracture under mechanical impact or vibration.

- Higher manufacturing cost: Requires precision extrusion equipment and high-temperature sintering.

- Greater pressure drop: Creates flow resistance for gases.

- Thermal shock stability: Thin walls can crack under rapid temperature changes (cordierite performs relatively well).

- Difficult maintenance: Once clogged or damaged, the entire unit usually must be replaced.

5. Frequently Asked Questions (FAQ)

Q: What is another name for it?

A: Ceramic honeycomb is also known as ceramic honeycomb substrate, honeycomb ceramic monolith, or cordierite honeycomb substrate.

Q: How long does ceramic honeycomb last?

A: Service life typically ranges from 5–10 years or more, depending on temperature, corrosive media, and loading.

Q: What are common manufacturing mistakes?

- Incorrect raw material ratios → insufficient strength or cracking after sintering

- Defects in extrusion die design → uneven wall thickness or channel deformation

- Poor control of drying/sintering temperatures → internal stress cracks

- Issues with coating processes → affects catalytic performance

6. Conclusion

In 2025, ceramic honeycomb plays a pivotal role in emission reduction, energy efficiency, and sustainable development. While new energy vehicles present transformation challenges, applications in hybrid power systems, thermal management, and emerging filtration fields continue to expand rapidly, offering broad market prospects.

If you are a business owner, engineer, or interested in ceramic honeycomb products, contact professional suppliers for customized solutions and contribute to green technology innovation!

-

Explore how these processes enhance the efficiency and effectiveness of ceramic honeycomb applications. ↩

-

Discover how the porous design contributes to the performance and versatility of ceramic honeycomb materials. ↩

-

Gain insights into the role of ceramic honeycomb in reducing vehicle emissions through catalytic converters. ↩

-

Explore the significance of these filters in automotive technology and how ceramic honeycomb enhances their performance. ↩