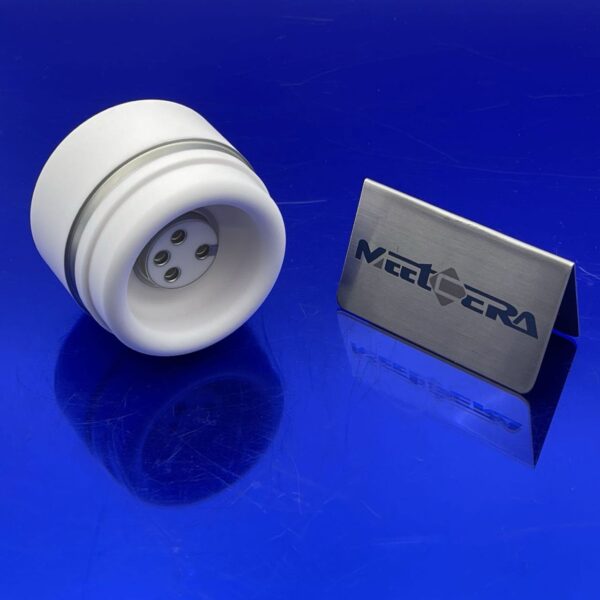

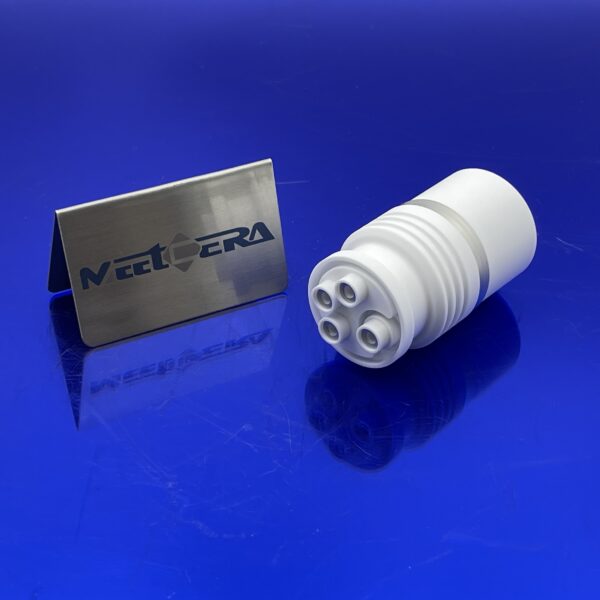

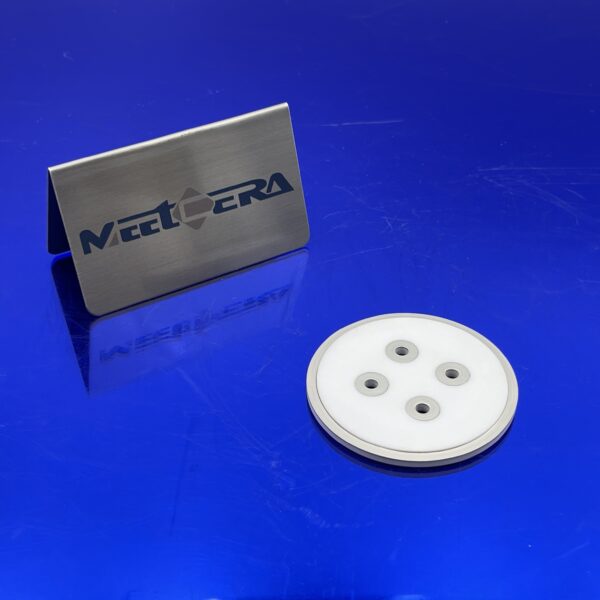

Ceramic Heater Element

MCH Ceramic Heating Element is produced by implementing unique metallization and ceramic lamination processes. Due to the advanced manufacturing techniques utilized in the electric element. Alumina heaters can provide higher reliability than ever before. Currently, applications include use as innovative types of heaters in the automotive, medical and semiconductor industries.

|

Specification:

|

||

|

Dimension

|

OD7*T0.6

|

Resistance range(Ω): 0.4-0.6

|

|

OD11*T0.8

|

Resistance range(Ω): 0.3-0.4

|

|

|

OD24*T1.2

|

Resistance range(Ω): 3.7-4.5/10-13/16-22/9-11/11.3-13.7

|

|

|

OD20*T1.2

|

Resistance range(Ω): 17-20/7.5-8.8/1.5-2.0

|

|

|

OD14*T1.2

|

Resistance range(Ω): 95-101/70-84/110-145/200-290/140-170/25.5-30.5/25-33/270-330/100-120

|

|

|

OD30*T1.2

|

Resistance range(Ω): 1.4-1.69/0.8-1.1/12-16/4-5/1.7-2.1/2.53-2.77/2.0-2.53/2.5-2.8

|

|

|

OD38*T1.2

|

Resistance range(Ω): 2.0-2.59/450-550/2.5-3.2/5-6/2.6-3.2

|

|

|

Rated Voltage

|

5V, 12V, 24V ( all can be customized )

|

|

|

Application

|

Heating Hemp, Moxibustion, Medical Device, Coffee Machine, Car Water Heatet Up … …

|

|

Design Structure

Ceramic Heaters are manufactured by printing resistors on alumina shees,being laminated and sintered into one pieces.

Types:

■ Rectangular alumina ceramic heating element

■ Round shape alumina ceramic heating element

■ Rod shape alumina ceramic heating element

■Tube shape alumina ceramic heating element