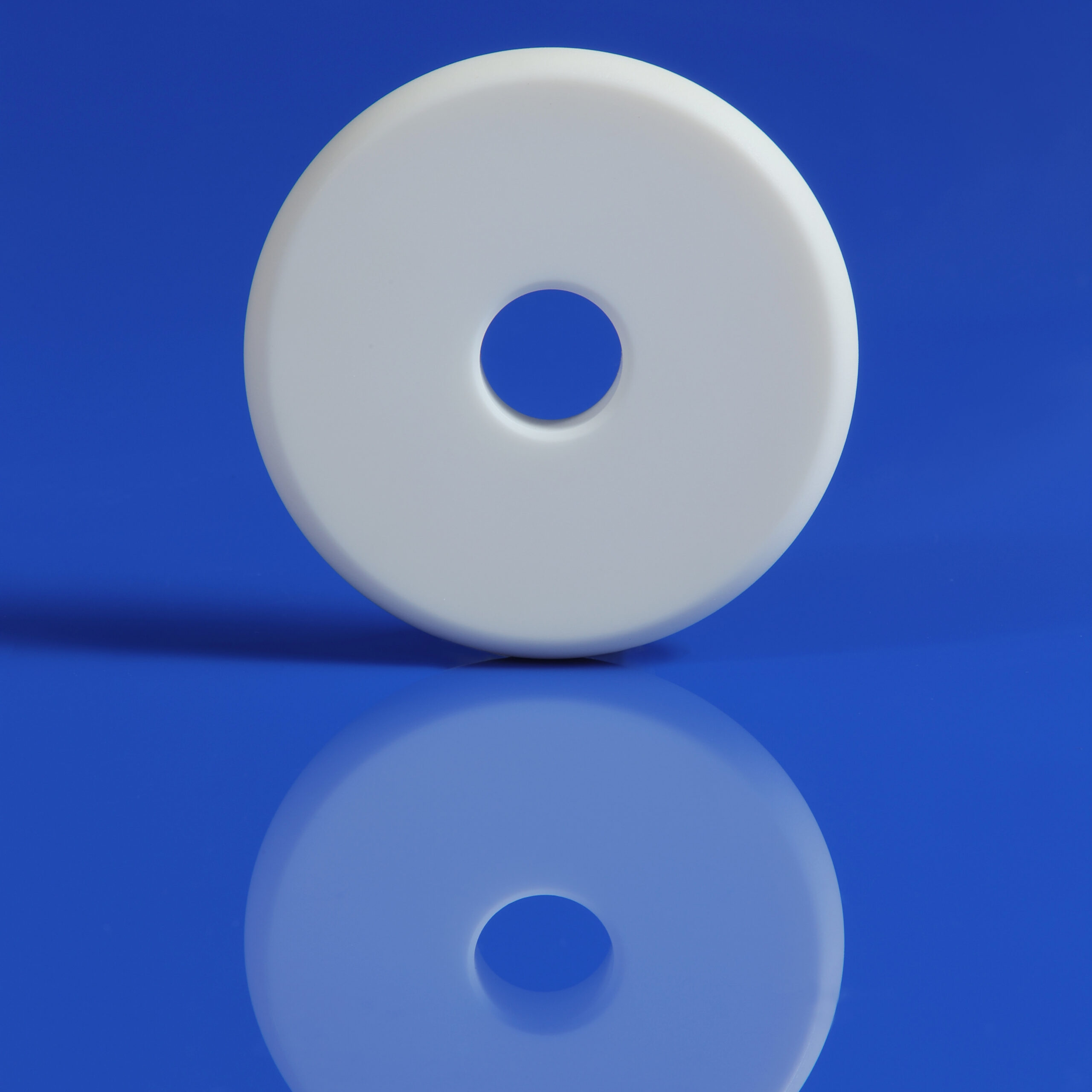

Alumina Ceramic Friction Discs

Manufactured from high-purity alumina (Al₂O₃) precision ceramic material, this product is specially designed for false twist texturing machines (DTY texturing machines) and draw texturing machine triple-axis friction units. It serves as an upgraded replacement for traditional polyurethane (PU) discs and metal discs.

Through diamond mirror polishing technology, it achieves ultra-low yarn tension, zero yarn damage, exceptionally long service life, and superior yarn cleanliness. It is widely applied in the false twist texturing process for chemical fibers such as polyester, nylon, and polypropylene.

Key Features

- Exceptional wear resistance and hardness – far superior to metal and PU discs, delivering 3–10× longer service life

- Extremely low yarn tension with zero yarn damage – significantly improves yarn quality and evenness

- Highest yarn cleanliness – completely free from lint, breaks, contamination, static, or other defects

- Superior thermal conductivity and thermal shock resistance – ideal for high-speed, high-temperature, and corrosive production environments

Product Advantages

- Compared to traditional PU discs: Superior thermal conductivity for rapid dissipation of frictional heat, preventing yarn overheating damage; service life improved by 3–10 times (depending on yarn type)

- Compared to metal discs: No static electricity, no magnetism, no wear particle contamination of yarn; results in lower yarn CV value and more even yarn evenness

- Mirror-polished contact surface design ensures smooth yarn path transition, achieving low tension + high twist stability

- Significantly reduces disc replacement frequency, minimizes downtime, and greatly enhances overall production efficiency

Typical Applications

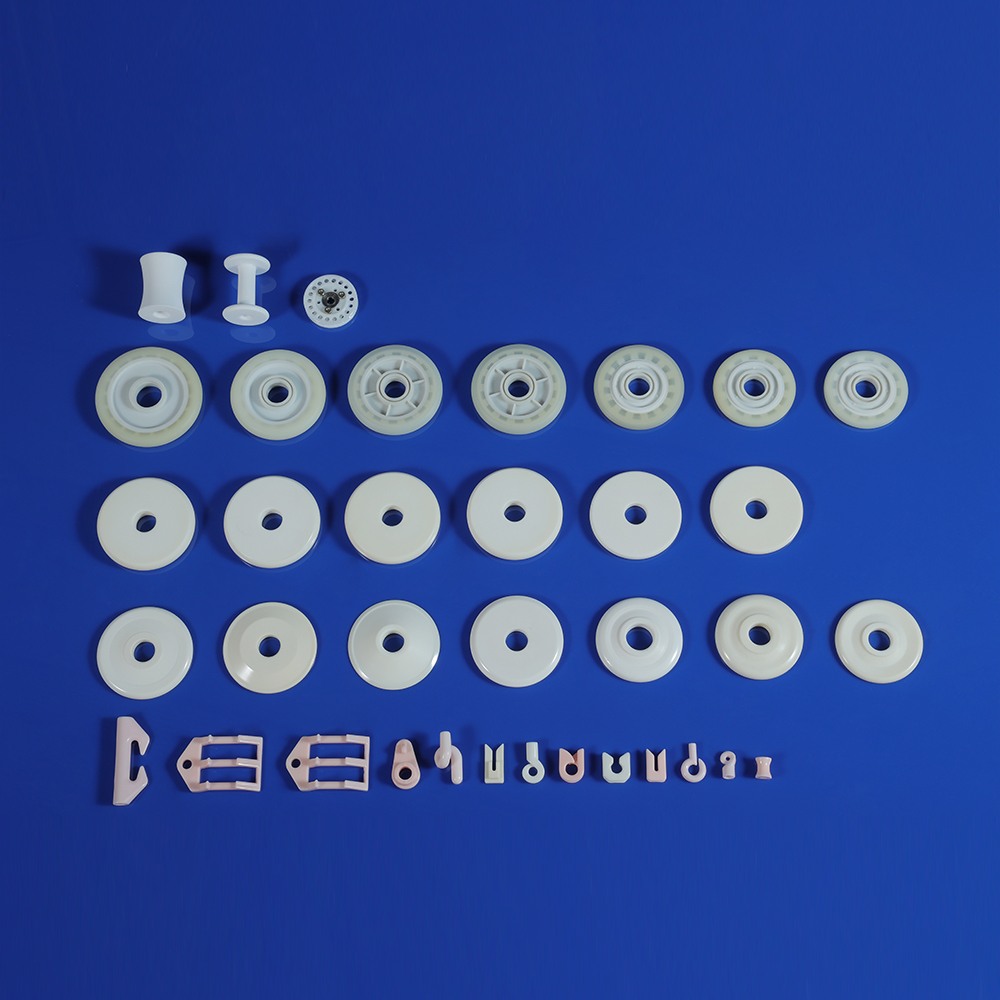

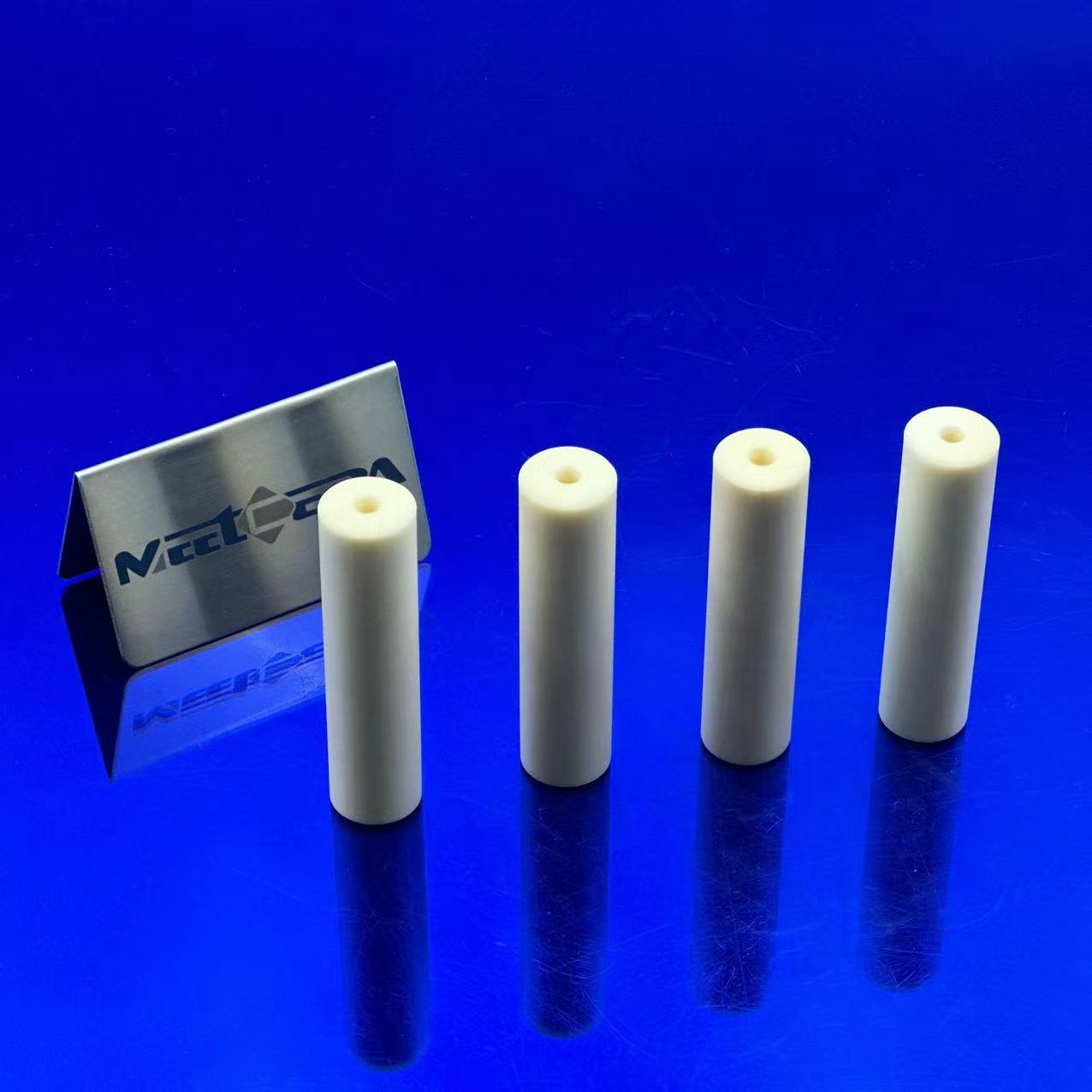

- Friction units in mainstream false twist texturing machines such as Barmag, Murata, SSM, Rieter

- POY → DTY, FDY texturing processes

- Polyester, nylon, spandex covered yarns, functional yarns (e.g., antibacterial, flame-retardant, conductive yarns)

- High-end civilian filaments, industrial yarns, air-textured yarns (ATY), and other fields with strict yarn quality requirements

Quality Assurance

- 100% non-destructive inspection (visual + ultrasonic / dimensional testing)

- Material test report provided for each batch (composition, density, hardness)

- Supports customization of dimensions, thickness, and surface roughness based on customer drawings/samples