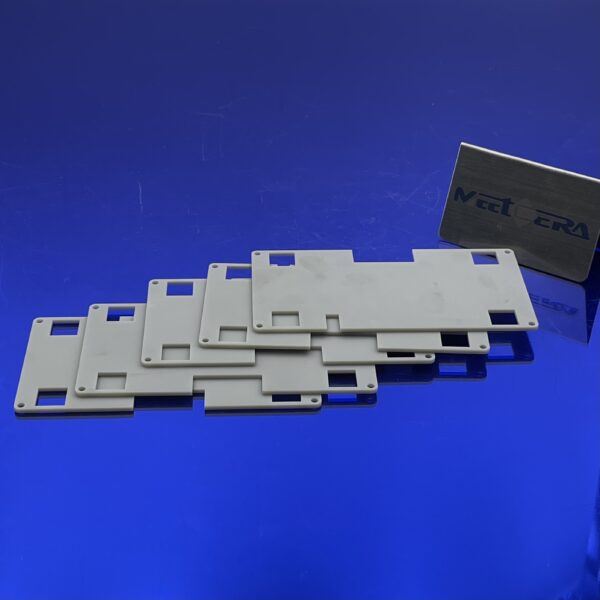

alumina ceramic block

Alumina, also known as Aluminum Oxide, is a hard wearing advanced technical ceramic material frequently used in a wide variety of

industrial applications. Once fired and sintered, it can only be machined using diamond-grinding methods. It features high

hardness and wear resistance, low erosion levels, high temperature resistance, corrosion resistance, and

bioinertness.Additionally, it can be highly polished, making it useful for a wide range of applications.Al2o3 Ceramic Disc Properties:

1. Good electrical insulation

2. Moderate thermal conductivity

3. High corrosion and wear resistance

4. Good gliding properties

5. High mechanical strength

6. High compressive strength

7. High hardness

industrial applications. Once fired and sintered, it can only be machined using diamond-grinding methods. It features high

hardness and wear resistance, low erosion levels, high temperature resistance, corrosion resistance, and

bioinertness.Additionally, it can be highly polished, making it useful for a wide range of applications.Al2o3 Ceramic Disc Properties:

1. Good electrical insulation

2. Moderate thermal conductivity

3. High corrosion and wear resistance

4. Good gliding properties

5. High mechanical strength

6. High compressive strength

7. High hardness

FEATURES AT A GLANCE

Advantage:

1.Purity:92%, 95%, 96%, 99%, 99.7%2.Good mechanical strength

3.Excellent electrical insulation

4.High-frequency loss

5.Good thermal conductivity

6.Heat, wear and corrosion resistance.

Application:

Alumina is the best-known advantaced ceramicmaterial, is widely used in

1.Automotive

2.Petro-chemical

3.Fluid control

4.Material transfer

5.Industry

6.Electrical and electronic

7.Semiconductor

8.Sapphire is single-crystal alumina.

Alumina is the best-known advantaced ceramicmaterial, is widely used in

1.Automotive

2.Petro-chemical

3.Fluid control

4.Material transfer

5.Industry

6.Electrical and electronic

7.Semiconductor

8.Sapphire is single-crystal alumina.

|

Alumina Ceramic Property

|

|||||

|

Property

|

Unit

|

92% Alumina Ceramic

|

95% Alumina Ceramic

|

99% Alumina Ceramic

|

|

|

Density

|

g/cm3

|

≥3.63

|

≥3.68

|

≥3.83

|

|

|

Water absorption

|

%

|

O

|

O

|

O

|

|

|

Sintering temperature

|

°C

|

1500-1700

|

1600-1800

|

1700-1800

|

|

|

Hardness

|

HV

|

≥1400

|

≥1500

|

≥1650

|

|

|

Flexural strength

|

Kgf/cm2

|

3000

|

3000

|

3000

|

|

|

Compressive strength

|

Kgf/cm2

|

24000

|

25000

|

26000

|

|

|

Fracture toughness

|

Map.m3/2

|

3~4

|

3~4

|

4~5

|

|

|

Maximum temperature

|

°C

|

1600

|

1700

|

1800

|

|

|

Coefficient of thermal expansion

|

/°C

|

8*10-6

|

8*10-6

|

8*10-6

|

|

|

Heat shock

|

T(°C)

|

220

|

220

|

220

|

|

|

Thermal conductivity

|

W/m.k(25-300°C)

|

25 14

|

25 14

|

25 14

|

|

|

20°C

|

>1012

|

>1012

|

>1012

|

||