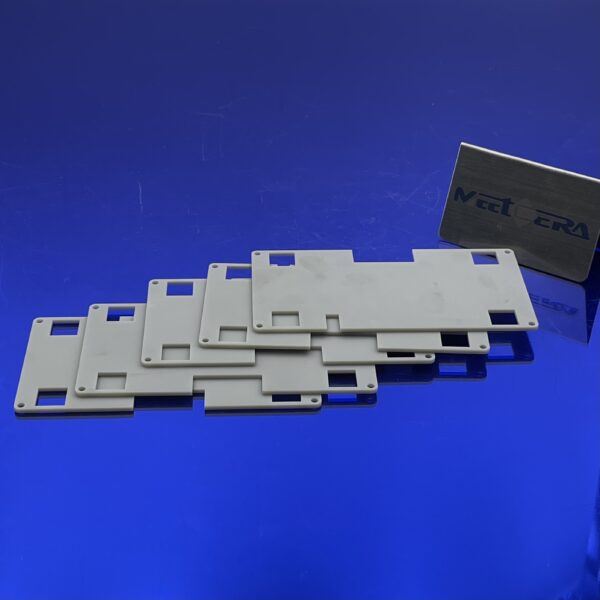

Alumina Aluminum AL2O3 Ceramic Water valve plate

1.Aluminum Oxide Ceramic is wildely used in many fields including mechanical, electronics, electrical,automotive, semiconductor,textile, etc. For the good propertities, more and more customers choose Alumina ceramic materials for their applications. Alumina Ceramic can be made to Ceramic Nozzles, Ceramic Sprayers Cyclones, Ceramic Linings, Milling Systems, Ceramic Thread guides, etc.Customized designs are very often to be made.

2.Alumina ceramics features:

1).Excellent electrical insulation

2).High hardness

3).Relatively low strength and fracture toughness

4).Resistance to wear and corrosive

5).Excellent thermal stability

6).Resistance to high temperatures

7).High electrical resistivity

8).Good chemical stability and resistance

9).High corrosion resistance

10).Excellent thermal shock resistance

11).High thermal insulation

12).A Low Young’s modulus

Advantage:

1.Purity:92%, 95%, 96%, 99%, 99.7%

2.Good mechanical strength

3.Excellent electrical insulation

4.High-frequency loss

5.Good thermal conductivity

6.Heat, wear and corrosion resistance.

3.Excellent electrical insulation

4.High-frequency loss

5.Good thermal conductivity

6.Heat, wear and corrosion resistance.

— Ceramic tubes are used when conditions exclude the use of metal, either for chemical reasons or because of excessive

temperatures.Their main applications are between 1000 and 1800°C.

— Ceramic tubes should be mounted in a hanging position above 1200°C to prevent distortion or fracture due to bending stresses.

temperatures.Their main applications are between 1000 and 1800°C.

— Ceramic tubes should be mounted in a hanging position above 1200°C to prevent distortion or fracture due to bending stresses.

|

Alumina Ceramic Property

|

|||||

|

Property

|

Unit

|

92% Alumina Ceramic

|

95% Alumina Ceramic

|

99% Alumina Ceramic

|

|

|

Density

|

g/cm3

|

≥3.63

|

≥3.68

|

≥3.83

|

|

|

Water absorption

|

%

|

O

|

O

|

O

|

|

|

Sintering temperature

|

°C

|

1500-1700

|

1600-1800

|

1700-1800

|

|

|

Hardness

|

HV

|

≥1400

|

≥1500

|

≥1650

|

|

|

Flexural strength

|

Kgf/cm2

|

3000

|

3000

|

3000

|

|

|

Compressive strength

|

Kgf/cm2

|

24000

|

25000

|

26000

|

|

|

Fracture toughness

|

Map.m3/2

|

3~4

|

3~4

|

4~5

|

|

|

Maximum temperature

|

°C

|

1600

|

1700

|

1800

|

|

|

Coefficient of thermal expansion

|

/°C

|

8*10-6

|

8*10-6

|

8*10-6

|

|

|

Heat shock

|

T(°C)

|

220

|

220

|

220

|

|

|

Thermal conductivity

|

W/m.k(25-300°C)

|

25 14

|

25 14

|

25 14

|

|

|

|

20°C

|

>1012

|

>1012

|

>1012

|

|