High-Purity Zirconia Ceramic Crucible

Zirconia Ceramic Crucible is a high-performance container for laboratory and industrial use, primarily made from zirconia (ZrO₂) material. This crucible is renowned for its exceptional high-temperature resistance, corrosion resistance, and mechanical strength, and is widely applied in fields such as high-temperature melting, chemical analysis, and material synthesis. Zirconia ceramic crucibles are manufactured using advanced ceramic forming and sintering processes, ensuring a smooth surface free from impurity contamination, making them suitable for experimental environments with extremely high purity requirements.

Key Performance:

- Maximum operating temperature: 1900–2000°C in air for long-term use; up to 2100–2200°C in vacuum/inert atmosphere

- Excellent chemical stability: Virtually no wetting or contamination of precious metals (Pt, Pd, Rh, Ir, Au, etc.), superalloys, or acidic slags

- Outstanding thermal shock resistance: Withstands rapid temperature changes without cracking (recommended ramp rate ≤5°C/min)

- Extremely low thermal expansion + high density: Excellent dimensional stability, service life typically 2–5× longer than alumina crucibles

Typical Application Scenarios:

- Refining and casting of precious metals and platinum-group metals (Pt, Pd, Rh, Ir, etc.)

- Laboratory melting and small-batch prototyping of high-temperature alloys and superalloys

- High-temperature calcination and sintering of rare-earth compounds and specialty ceramic powders

- High-temperature melting experiments for optical glass and luminescent materials

FAQ

Q1: What is the biggest advantage of zirconia crucibles compared to alumina crucibles?

A: Much higher maximum temperature (up to >2200°C), stronger chemical inertness (especially no contamination of precious metals), and typically 2–5× longer service life.

Q2: What should I pay most attention to during use?

A: Avoid extreme thermal shock — recommended heating/cooling rate ≤5°C/min; never subject to mechanical impact; use slower rates for large sizes or fast processes.

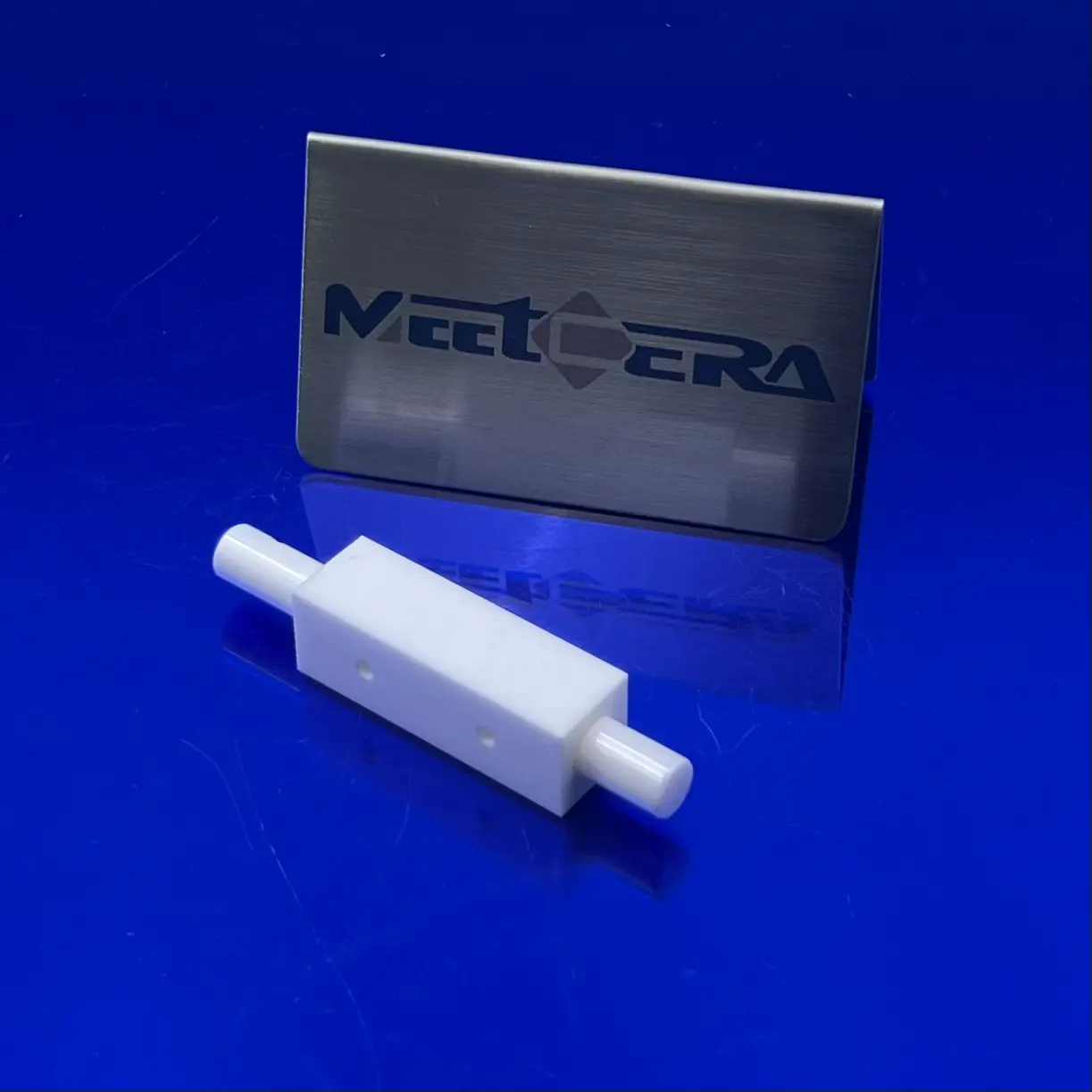

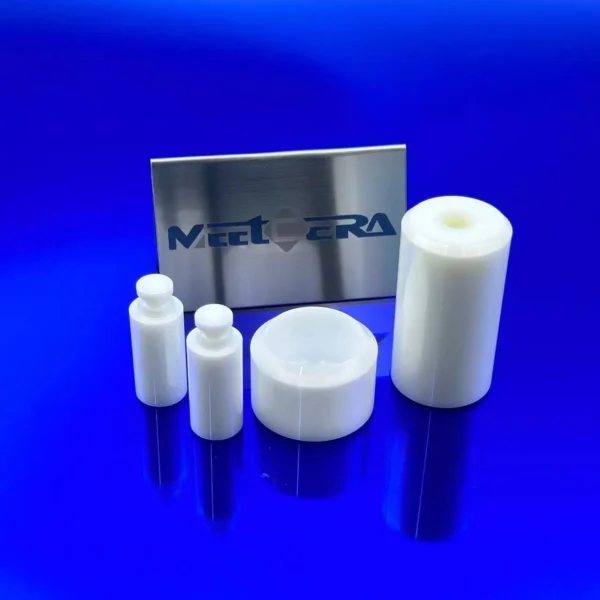

Q3: Can you provide custom sizes and shapes?

A: Yes — we support cylindrical, tall-form, lidded, boat, square, and many other shapes, with capacities from 5 ml to 500 ml+, and welcome drawings or specific requirements for custom production.