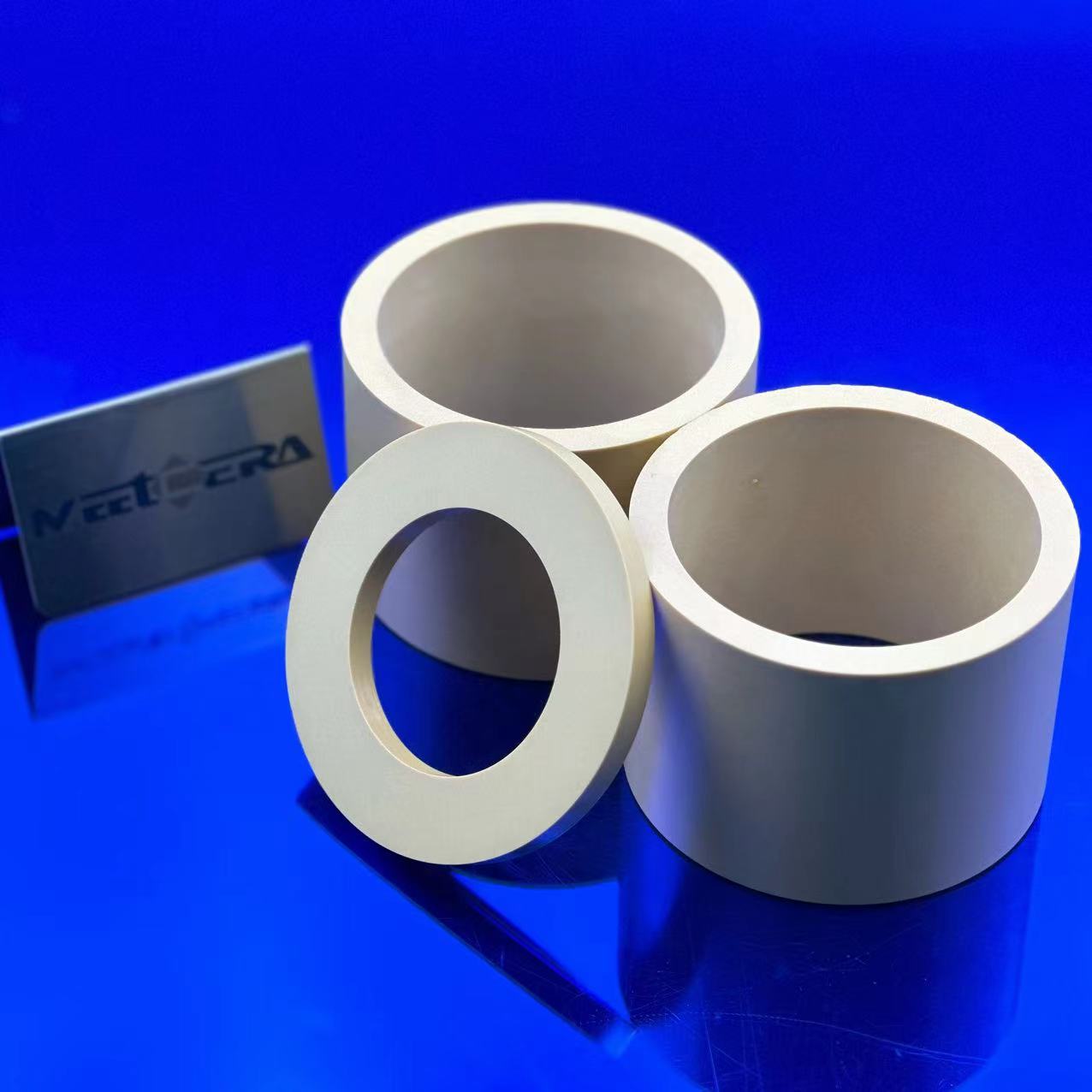

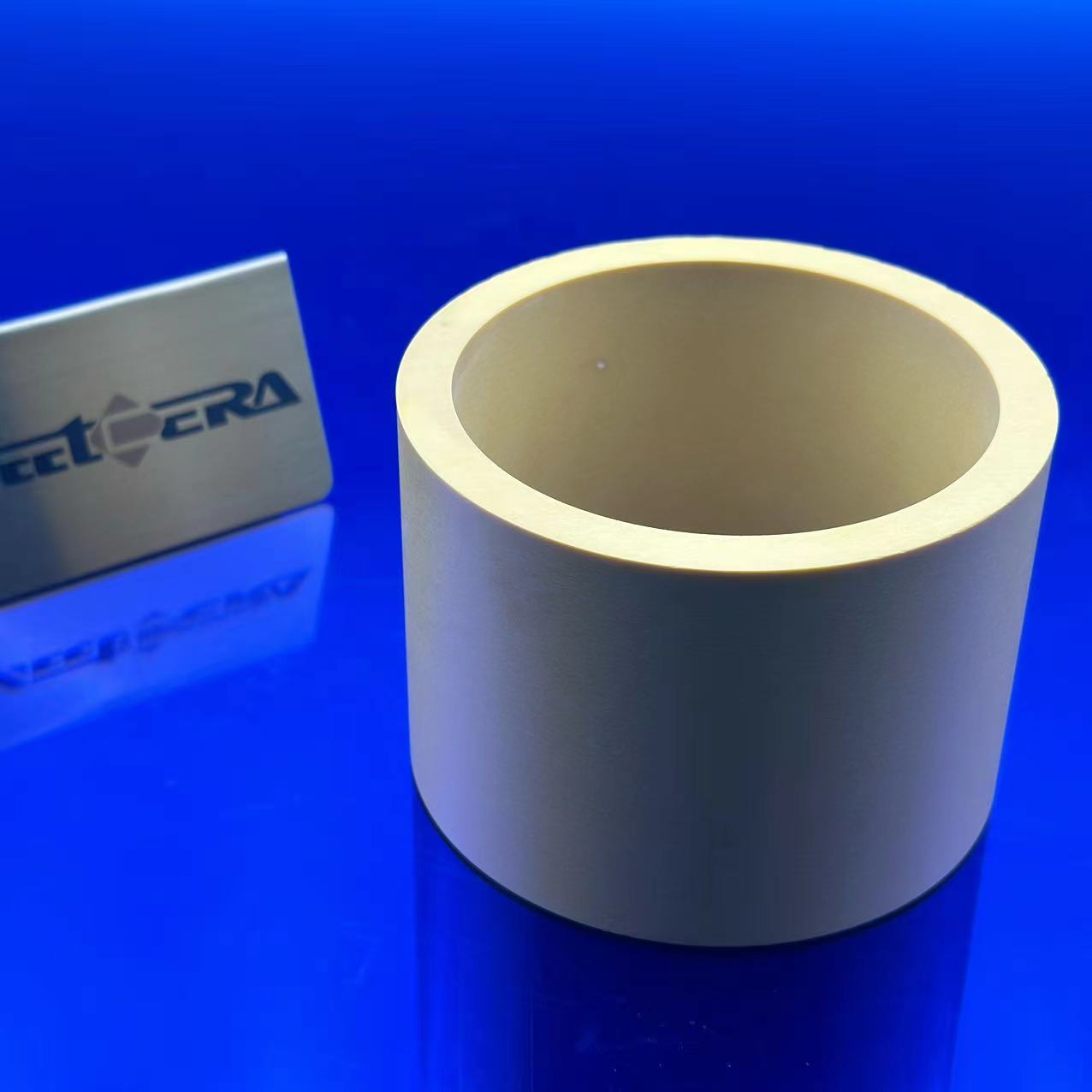

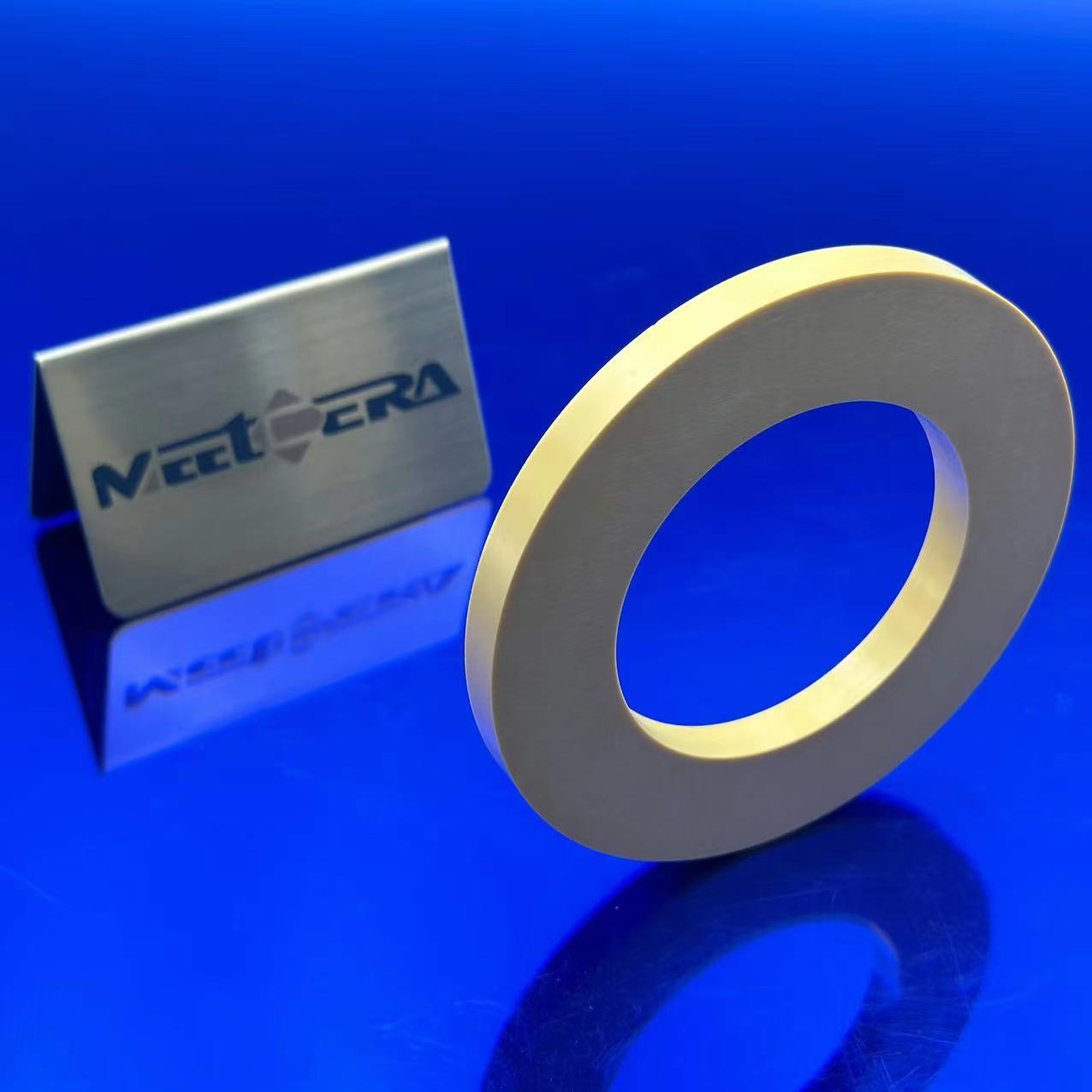

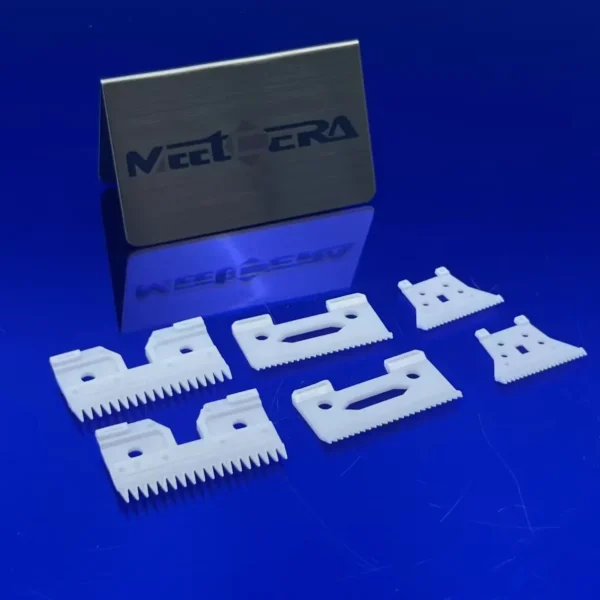

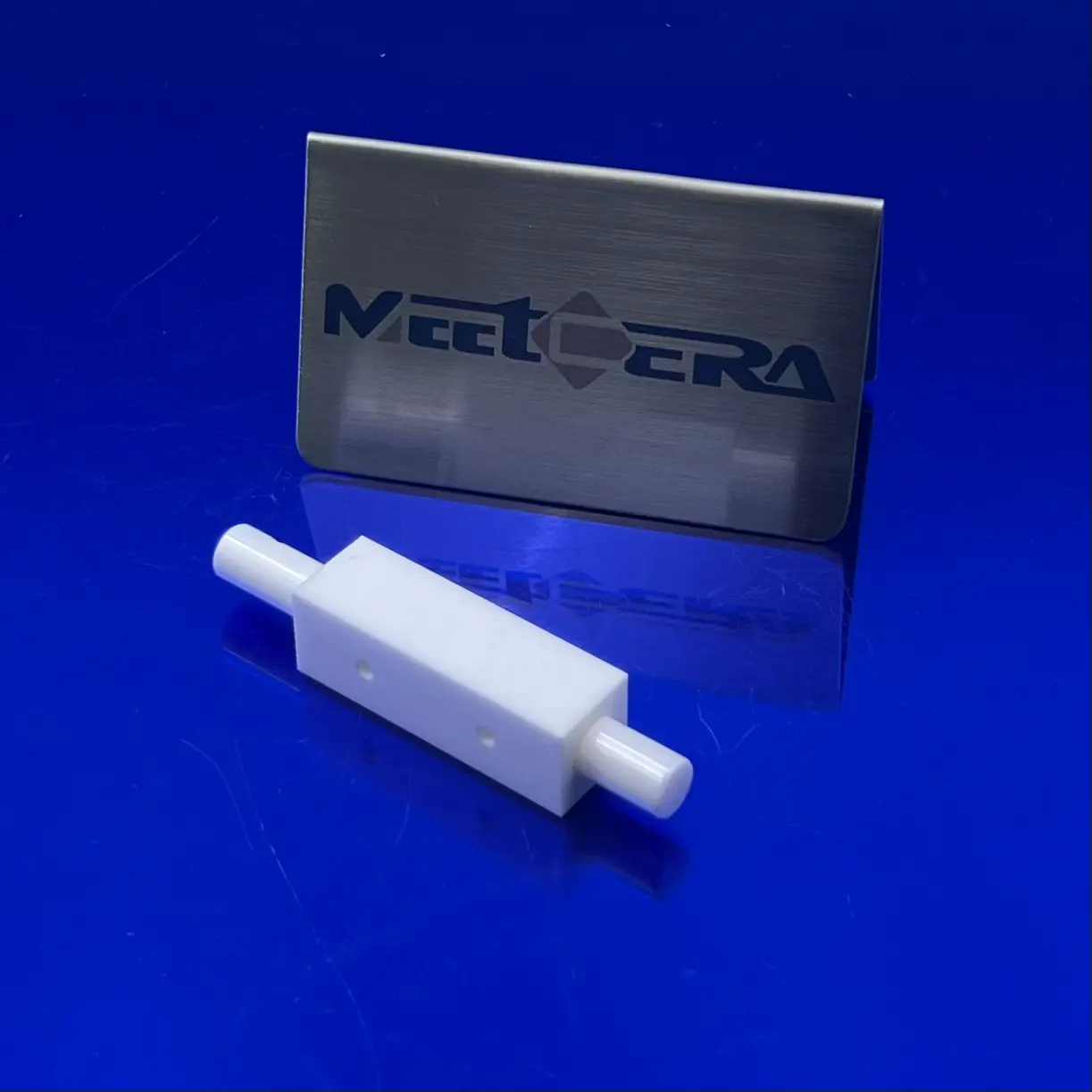

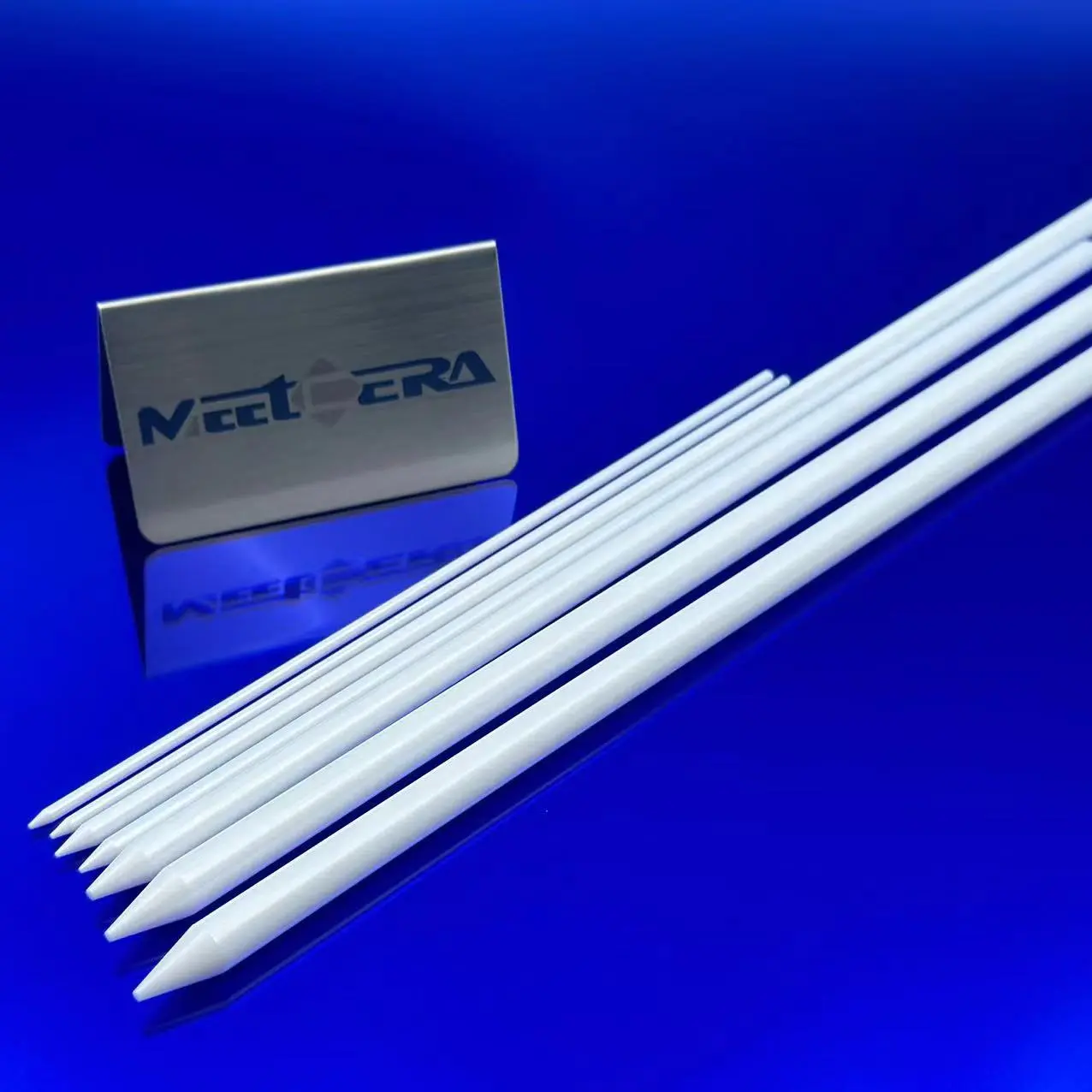

Mg-Stabilized Zirconia Tube

The Mg-Stabilized Zirconia Tube is a premium ceramic component designed for high-temperature and corrosive environments. Stabilized with magnesium oxide (MgO), this zirconia (ZrO2) tube offers enhanced thermal shock resistance, mechanical strength, and longevity compared to unstabilized zirconia. It is ideal for applications requiring structural integrity under extreme conditions, such as in furnaces, sensors, and chemical processing equipment. The stabilization process prevents phase transformations, ensuring consistent performance and reliability in demanding industrial settings.

Key Features:

- Material Composition: High-purity zirconia stabilized with 3-5% MgO for improved toughness and phase stability, preventing cracking during thermal cycling.

- High Thermal Resistance: Withstands temperatures up to 2,200°C, with excellent thermal insulation properties.

- Superior Mechanical Properties: High fracture toughness (8-10 MPa·m¹/²) and bending strength (>500 MPa), making it resistant to mechanical stress and impact.

- Corrosion and Wear Resistance: Inert to most acids, alkalis, and molten metals, outperforming metals and other ceramics in aggressive environments.

- Customization Options: Available in various dimensions (inner diameter: 5-100 mm, outer diameter: 10-150 mm, length: up to 2,000 mm) with options for custom coatings or threading.

Benefits:

- Enhanced Durability: Exceptional resistance to thermal shock (ΔT > 500°C) reduces failure rates and extends operational life, minimizing downtime.

- Improved Efficiency: Low thermal conductivity (2-3 W/m·K) helps maintain temperature gradients, ideal for insulation and heat management.

- Cost Savings: Longer service life in harsh conditions lowers replacement and maintenance costs, providing a high return on investment.

- Versatility: Lightweight (density ~5.7 g/cm³) yet robust, suitable for both static and dynamic applications without compromising performance.

- Environmental Compatibility: Non-toxic and recyclable, aligning with sustainable manufacturing practices.

Applications:

- High-Temperature Furnaces: Protective tubes for thermocouples and heating elements in metallurgical and glass industries.

- Chemical Processing: Liners for reactors handling corrosive fluids and gases.

- Sensors and Instrumentation: Oxygen sensors, pH probes, and analytical equipment in automotive and environmental monitoring.

- Aerospace and Energy: Insulation components in turbines, fuel cells, and nuclear applications.

- Medical and Laboratory: Biocompatible tubes for high-purity processing in pharmaceuticals and research.

Why Choose Our Mg-Stabilized Zirconia Tube?

Manufactured using advanced sintering techniques and certified to ISO 9001 standards, our Mg-stabilized zirconia tubes deliver unparalleled quality and performance. Whether for prototyping or large-scale production, we offer tailored solutions to meet your exact specifications. Contact us today for quotes, samples, or technical consultations to optimize your systems.