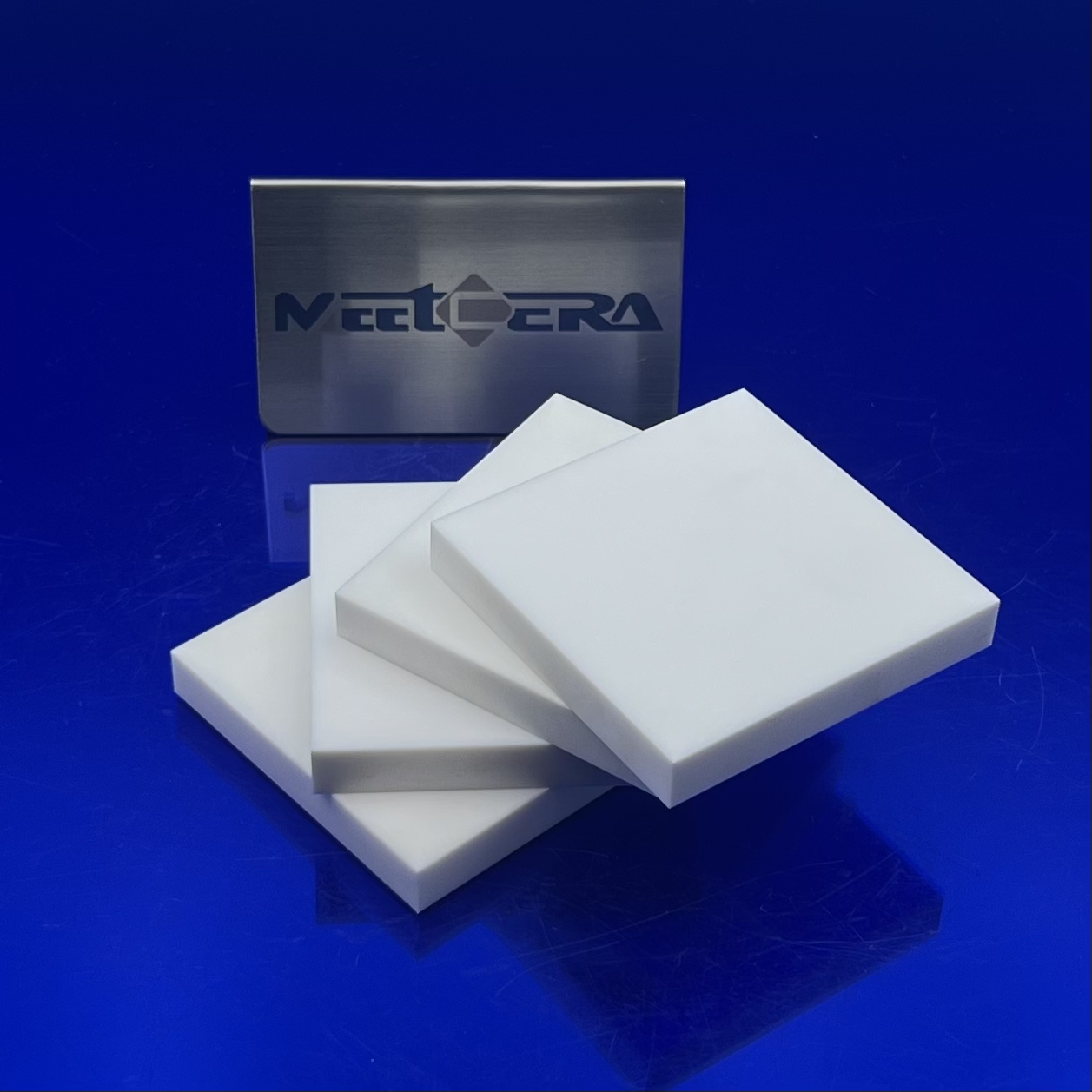

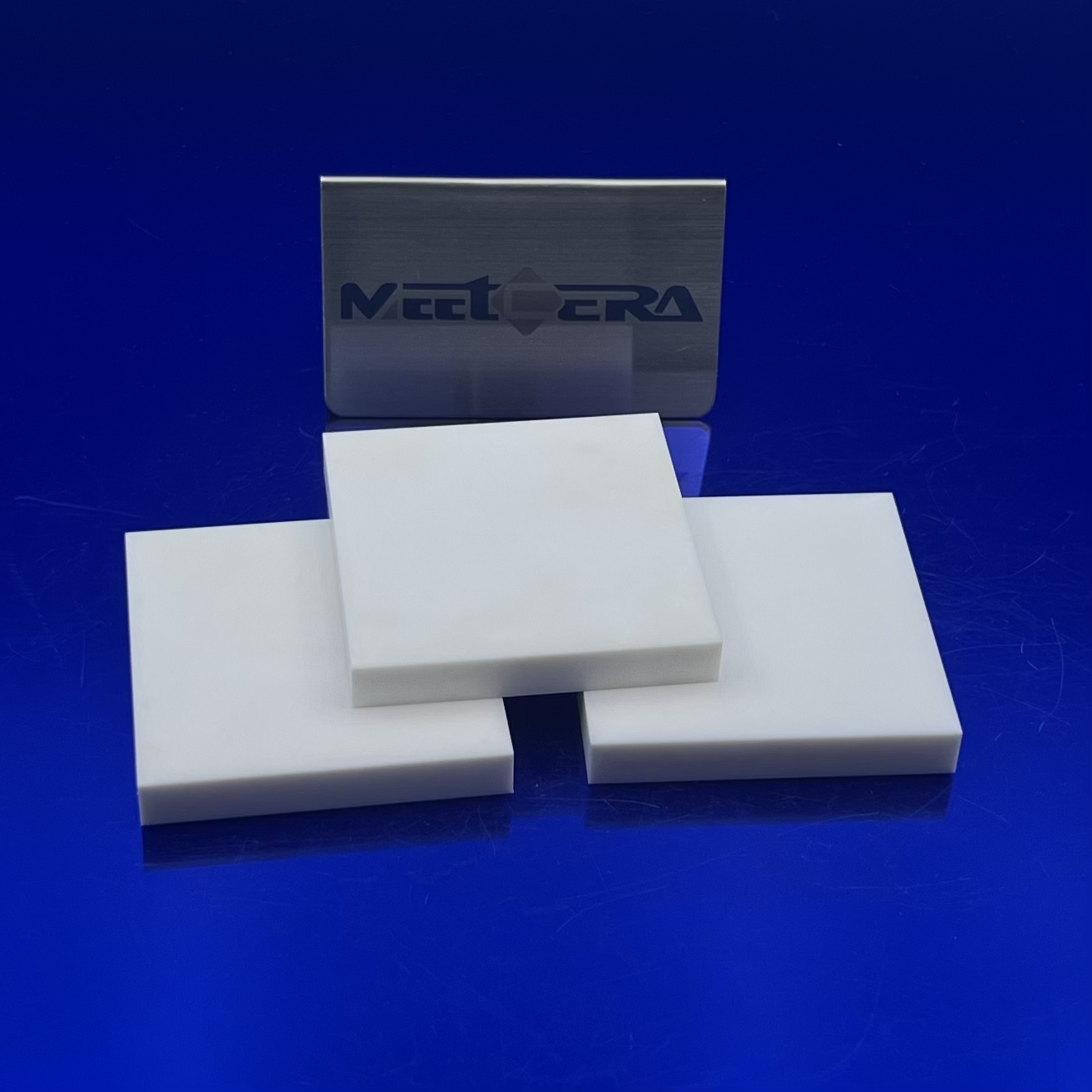

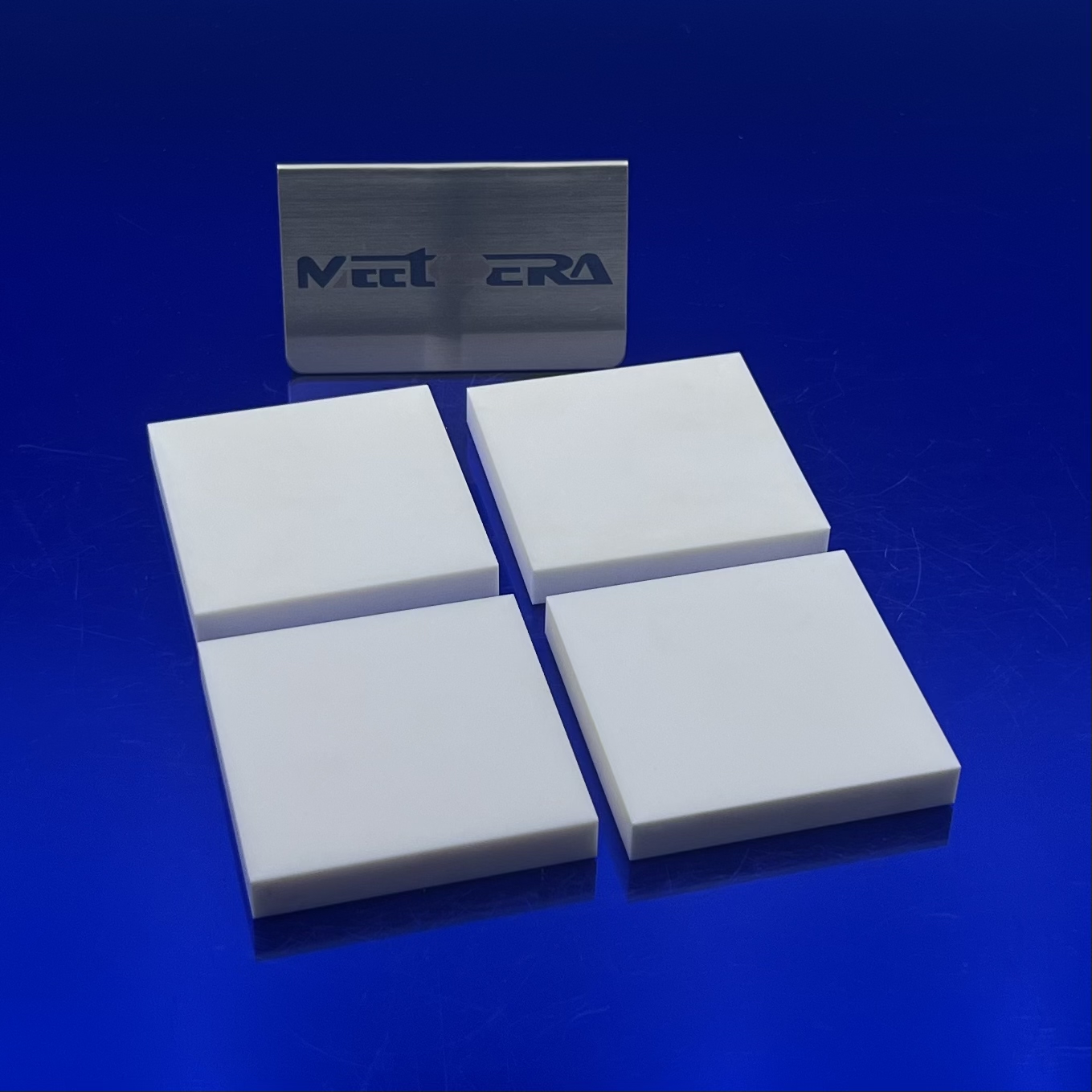

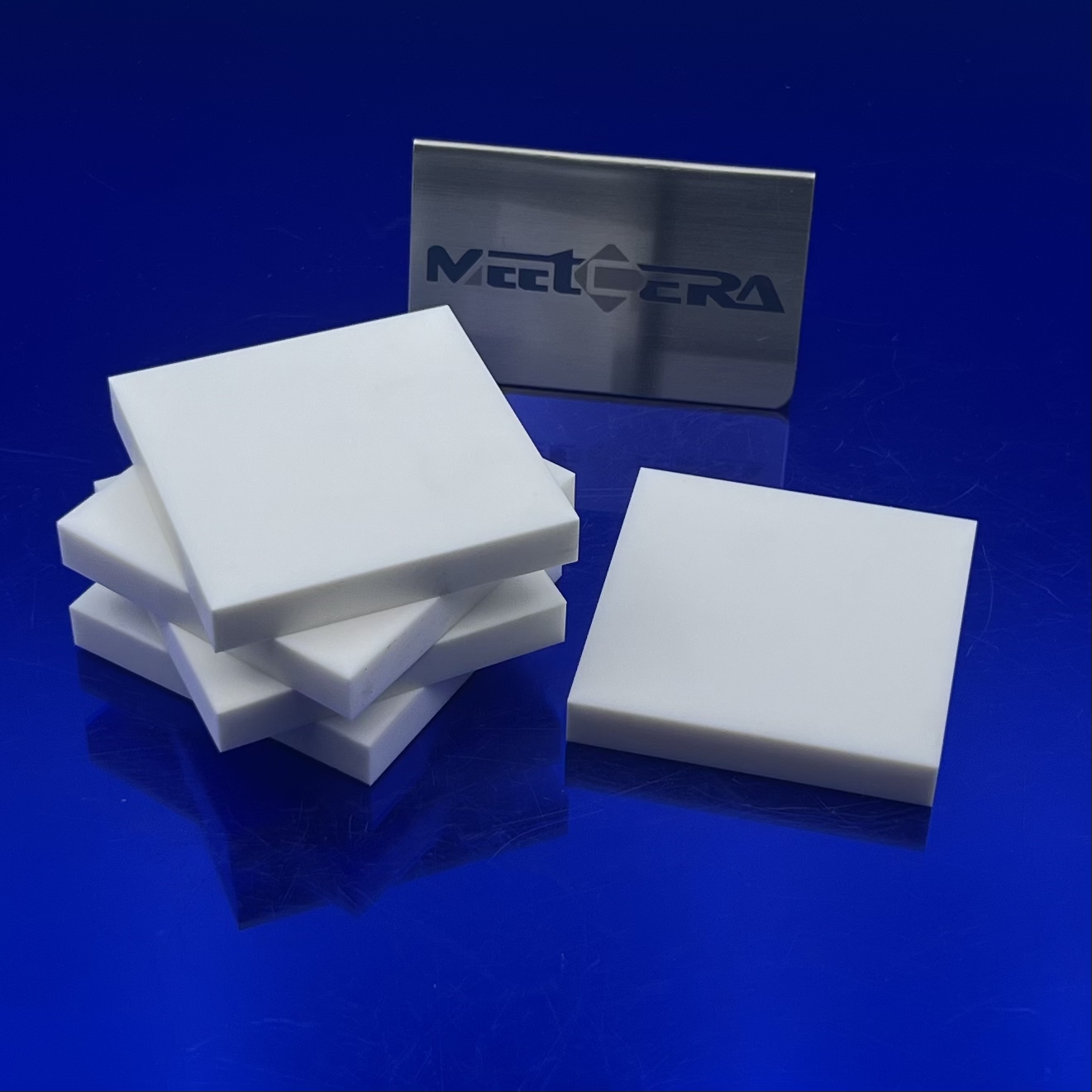

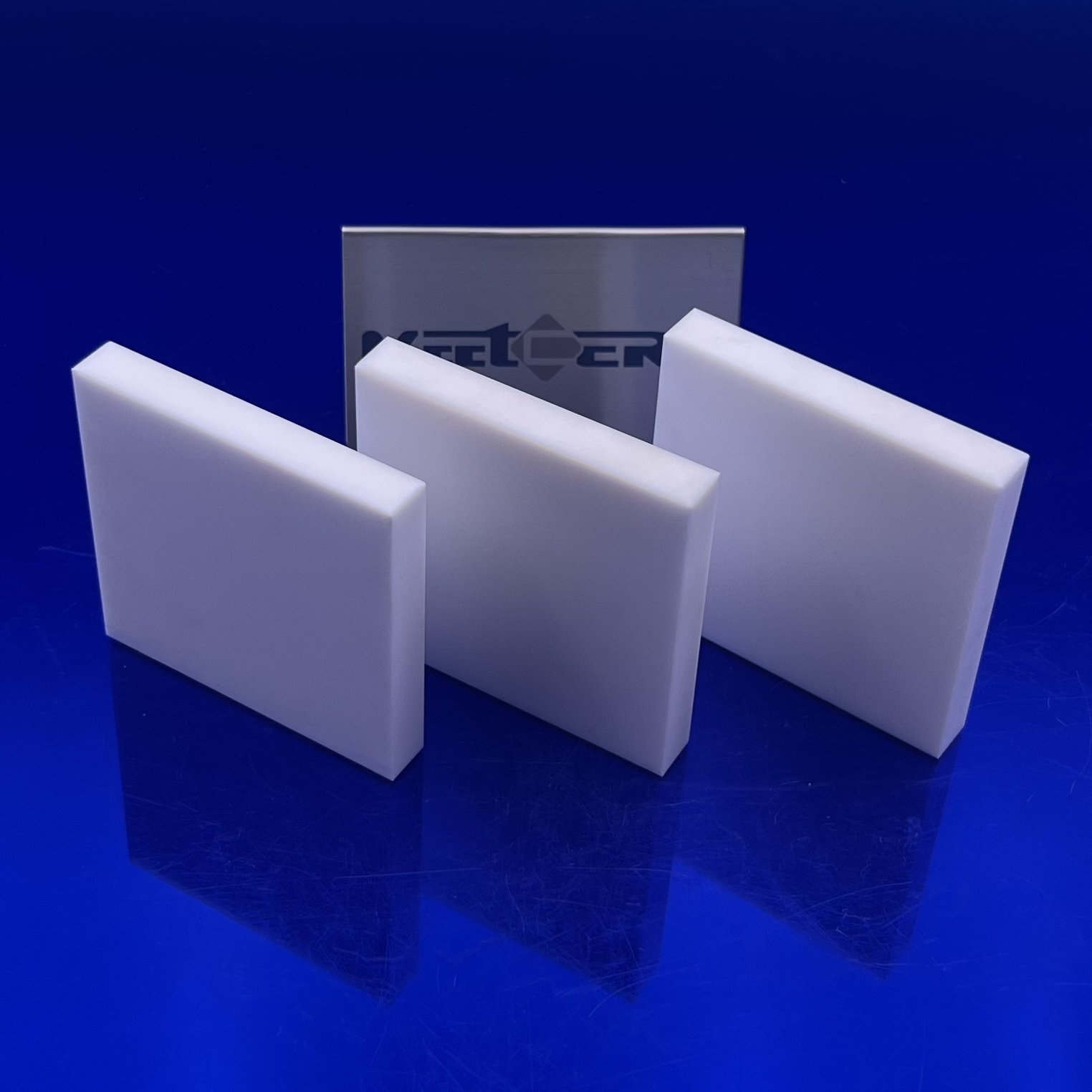

Rectangular Macor Sheets

Macor machinable glass ceramic is a unique high-performance material developed by Meetcera. It perfectly combines the easy machinability of glass with the excellent physical properties of advanced ceramics. With its distinctive white, porcelain-like appearance, Macor can be precisely machined into complex components using standard metalworking tools—no post-firing required. This significantly shortens production lead times.

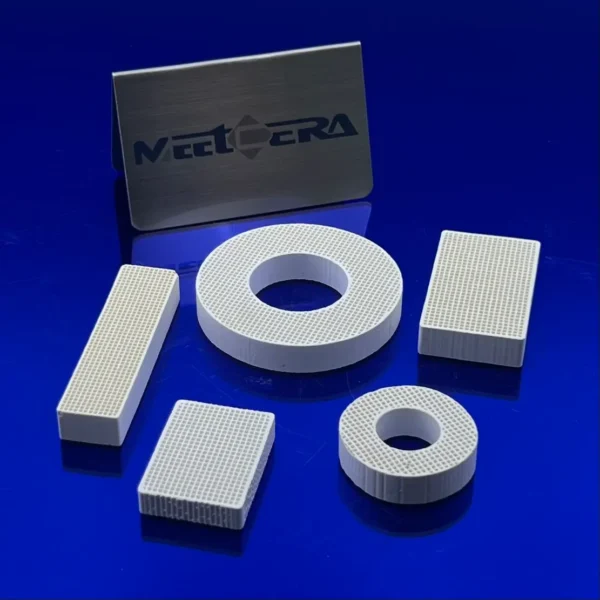

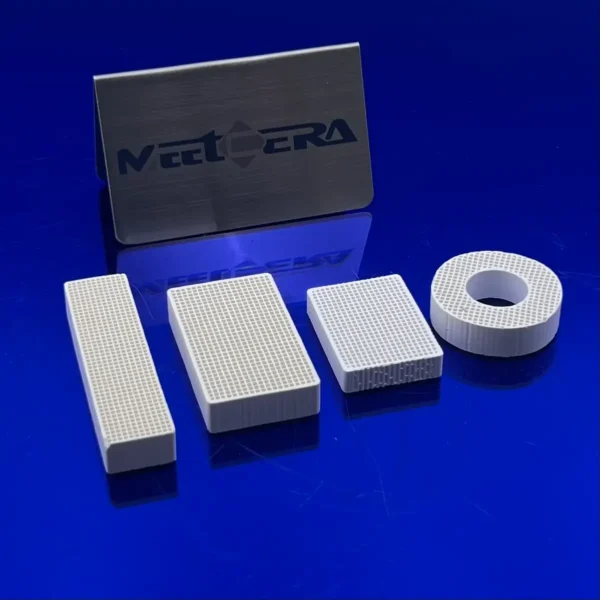

Whether you need standard plates, rods, or fully custom high-temperature precision machined Macor ceramic parts, it is the preferred material in high-end industries such as semiconductors, aerospace, medical devices, and vacuum systems.

Core Advantages of Macor Machinable Glass Ceramic

- Exceptional Machinability: Can be easily turned, milled, drilled, tapped, and ground using ordinary carbide tools on conventional metalworking equipment. Achieves micron-level precision and is ideal for custom precision machined Macor ceramic components and intricate geometries.

- Outstanding High-Temperature Performance: Continuous use up to 800°C, with short-term peaks reaching 1000°C (unloaded). Maintains excellent dimensional stability at high temperatures without creep or deformation—perfect for high-temperature precision Macor ceramic parts.

- Superior Electrical Insulation: Extremely high dielectric strength and volume resistivity, even under high temperature and high vacuum conditions. The top choice for vacuum insulation Macor ceramic rods and electronic device supports.

- Zero Porosity & Ultra-Low Outgassing: Fully dense structure with excellent vacuum compatibility, widely used in high-vacuum feedthroughs and semiconductor process chambers.

- Low Thermal Conductivity & Excellent Thermal Matching: Thermal conductivity of approximately 1.46 W/m·K and a coefficient of thermal expansion that closely matches many metals and sealing glasses, making it easy to metallize or hermetically seal.

- Additional Benefits: Radiation resistant, non-magnetic, highly polishable, good thermal shock resistance, and strong chemical stability.

Typical Applications

- Semiconductor & Electronics: Vacuum chamber components, insulating supports, RF windows, and other semiconductor equipment Macor glass ceramic parts.

- Aerospace & Defense: High-temperature insulation components and sensor housings.

- Medical Devices: Precision non-magnetic parts and laser equipment supports requiring biocompatibility and tight tolerances.

- Vacuum & Laser Systems: Vacuum feedthroughs, mirror mounts, and windows—especially high-vacuum Macor ceramic rods and components.

- Nuclear & Others: Radiation-resistant structures and high-temperature furnace insulation parts.

Why Choose Our Macor Machinable Glass Ceramic?

We provide a complete one-stop service from raw material to finished parts, including standard plates (thickness 0.5–50 mm), rods (diameter 3–100 mm), and custom Macor ceramic machining. With extensive machining experience, we can deliver complex geometries and tight tolerances to help you accelerate prototyping and scale to production quickly, significantly reducing development costs.

Frequently Asked Questions

Q: What are the advantages of Macor machinable glass ceramic compared to traditional alumina ceramics?

A: The biggest advantage is machinability. Unlike conventional ceramics that require diamond tools and often post-firing, Macor can be machined like metal, making it perfect for small-batch, high-variety precision machined Macor ceramic parts.

Q: Is Macor suitable for vacuum applications?

A: Absolutely. Its zero-porosity and extremely low outgassing properties make it a classic choice for vacuum insulation Macor ceramic in high and ultra-high vacuum environments.

Q: What is the maximum operating temperature?

A: Continuous use up to 800°C and short-term peaks up to 1000°C—far exceeding most engineering plastics and many other ceramics.

Q: Do you support custom parts?

A: Yes. We offer full high-temperature precision machined Macor ceramic parts customization according to your drawings. Feel free to send your designs for a quote.

Need Macor machinable glass ceramic plates, rods, or custom machined components? Contact us today for the latest pricing and technical support. We specialize in providing reliable easy-to-machine high-temperature glass ceramic material solutions for demanding applications.