Do You Know the Difference Between Vacuum and Hermeticity in Brazed Ceramics?

In high-reliability industries such as vacuum technology, aerospace, power electronics, and sensors, brazed ceramic-to-metal components play a crucial role in ensuring system integrity. However, two technical terms often cause confusion — vacuum level and hermeticity.

While they are closely related, they describe different aspects of performance. Understanding the difference is essential when evaluating the sealing quality of brazed ceramics used in vacuum or high-pressure environments.

What Is Vacuum Level?

The vacuum level refers to the pressure inside a sealed or evacuated system, typically measured in Pascal (Pa) or Torr.

It indicates how “clean” or “empty” the internal atmosphere is — the lower the pressure, the higher the vacuum.

In practical terms:

- A system operating at 10⁻⁵ Pa to 10⁻⁹ Pa is considered ultra-high vacuum.

- Maintaining such vacuum levels requires not only efficient pumping but also an airtight enclosure — and that’s where brazed ceramics come in.

What Is Hermeticity?

Hermeticity describes the ability of a sealed component to prevent gas leakage or penetration.

It’s a measure of how effectively a brazed ceramic joint resists air or gas permeation over time.

This property is usually verified through a helium leak test (He leak test), following standards such as MIL-STD-883 or MIL-STD-750.

A high-performance brazed ceramic assembly typically achieves:

Leak rate ≤ 1×10⁻⁹ Pa·m³/s

Such tight hermetic sealing ensures that the vacuum environment inside a device remains stable for years of operation.

How Are Vacuum Level and Hermeticity Related?

In short:

Hermeticity determines whether a vacuum level can be maintained.

- Vacuum level is the result — it shows how low the internal pressure is.

- Hermeticity is the cause — it determines whether gases can leak in or out.

If the hermeticity of a brazed ceramic assembly is poor, even a perfectly evacuated chamber will lose its vacuum over time.

Therefore, a strong, hermetic ceramic-to-metal seal is fundamental to achieving and sustaining ultra-high vacuum performance.

How Brazed Ceramics Achieve Hermetic Sealing

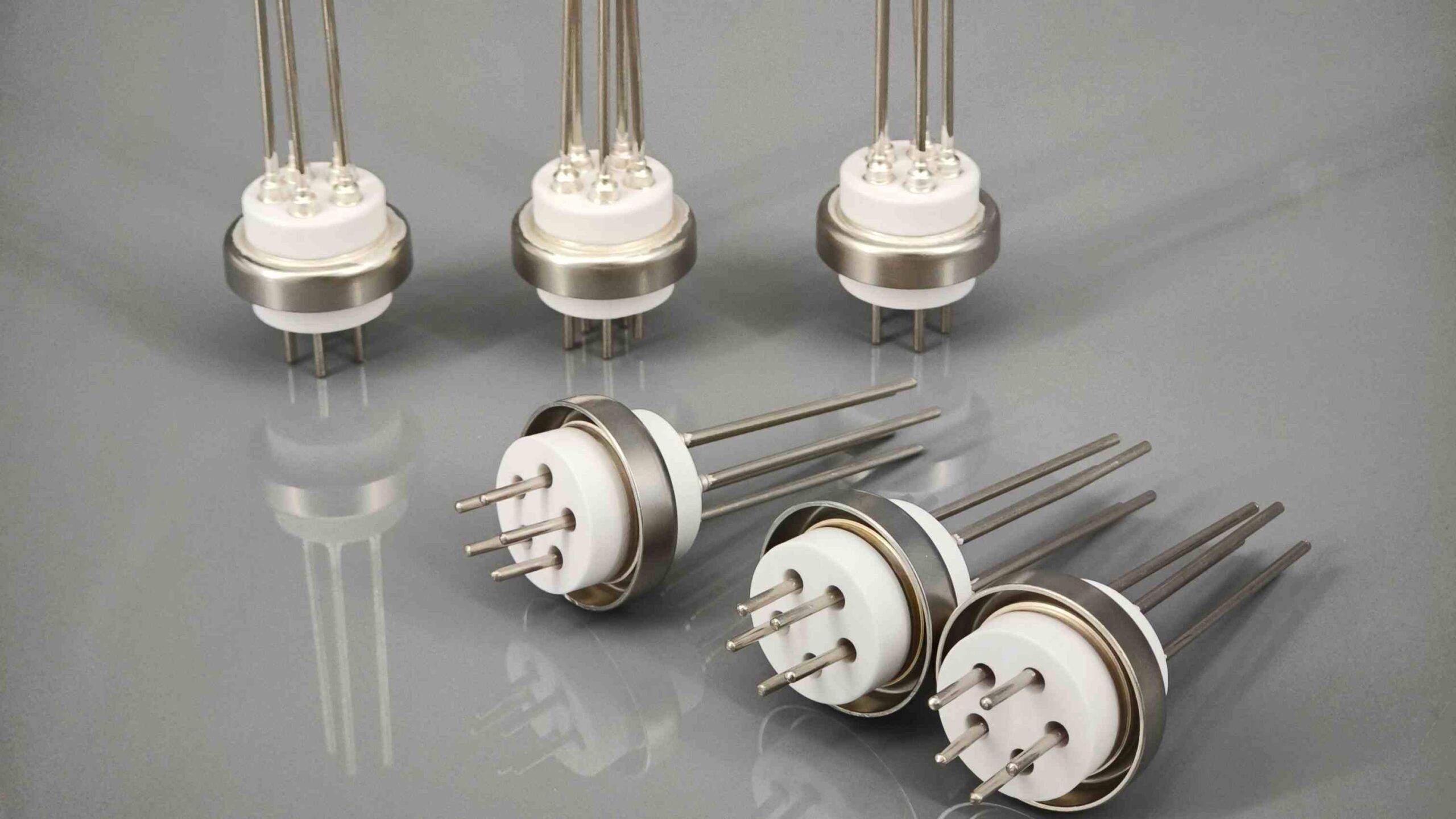

Brazed ceramics are made by joining ceramic materials (such as alumina) with metals (like Kovar or molybdenum) using a brazing alloy under high temperature.

The success of this process depends on:

- Material compatibility: Thermal expansion match between ceramic and metal

- Surface metallization: Mo-Mn and Ni plating ensure wetting during brazing

- Controlled atmosphere: Vacuum or hydrogen furnace brazing prevents oxidation

When done properly, the resulting joint is both mechanically strong and hermetically sealed — capable of withstanding thermal cycles, vibration, and high voltage stress.

Testing Hermeticity in Brazed Ceramics

Common testing methods include:

- Helium Leak Test: Detects microscopic gas leakage down to 1×10⁻¹⁰ Pa·m³/s

- Pressure Decay Test: Monitors internal pressure change over time

- Bubble Test: Used for larger parts under lower precision requirements

These tests ensure that each brazed ceramic component meets stringent vacuum and sealing standards before delivery.

Applications Requiring High Vacuum and Hermeticity

Brazed ceramic components are widely used in:

- Vacuum tubes and electron guns

- Feedthroughs and vacuum electrodes

- Power semiconductor packaging

- Medical and aerospace sensors

- Microwave and high-frequency devices

In all these fields, maintaining a stable vacuum environment is essential for long-term performance and reliability.

Related Reading

If you are interested in understanding how surface treatment improves the bonding strength between metal and ceramic, check out our related article:

👉 What Are Metallized Ceramics and How Do They Work?

This article explains the Mo-Mn metallization process, which is a key step before brazing and directly affects the final hermeticity of ceramic-to-metal assemblies.

Why Choose Meetcera Brazed Ceramics

At Meetcera, we specialize in producing custom brazed ceramic-to-metal components with exceptional hermeticity and vacuum stability.

Our advantages include:

- Leak rate down to 1×10⁻⁹ Pa·m³/s

- Ultra-clean vacuum brazing environment

- Material options including Al₂O₃, Kovar, Mo, and stainless steel

- Proven reliability across aerospace, power electronics, and vacuum industries

We work closely with engineers worldwide to deliver precision solutions tailored to demanding applications.

Conclusion

In summary, vacuum level and hermeticity are not the same — but they are fundamentally connected.

High hermeticity ensures that the vacuum level inside a brazed ceramic assembly remains constant over time, guaranteeing the stability and performance of critical systems.

If you are developing equipment that demands high-vacuum sealing, long-term reliability, and precise ceramic-to-metal integration, Meetcera offers the expertise and technology you can trust.