Metalized Ceramics Boost X-Ray Tube Insulation and Vacuum

Metalized ceramics are indispensable components in X-ray tubes. They deliver crucial high-voltage insulation and reliable vacuum sealing1, which directly enhances the overall performance and extends the operational lifespan of X-ray equipment. Understanding their applications and benefits is paramount for ensuring the reliability and safety of X-ray technology.

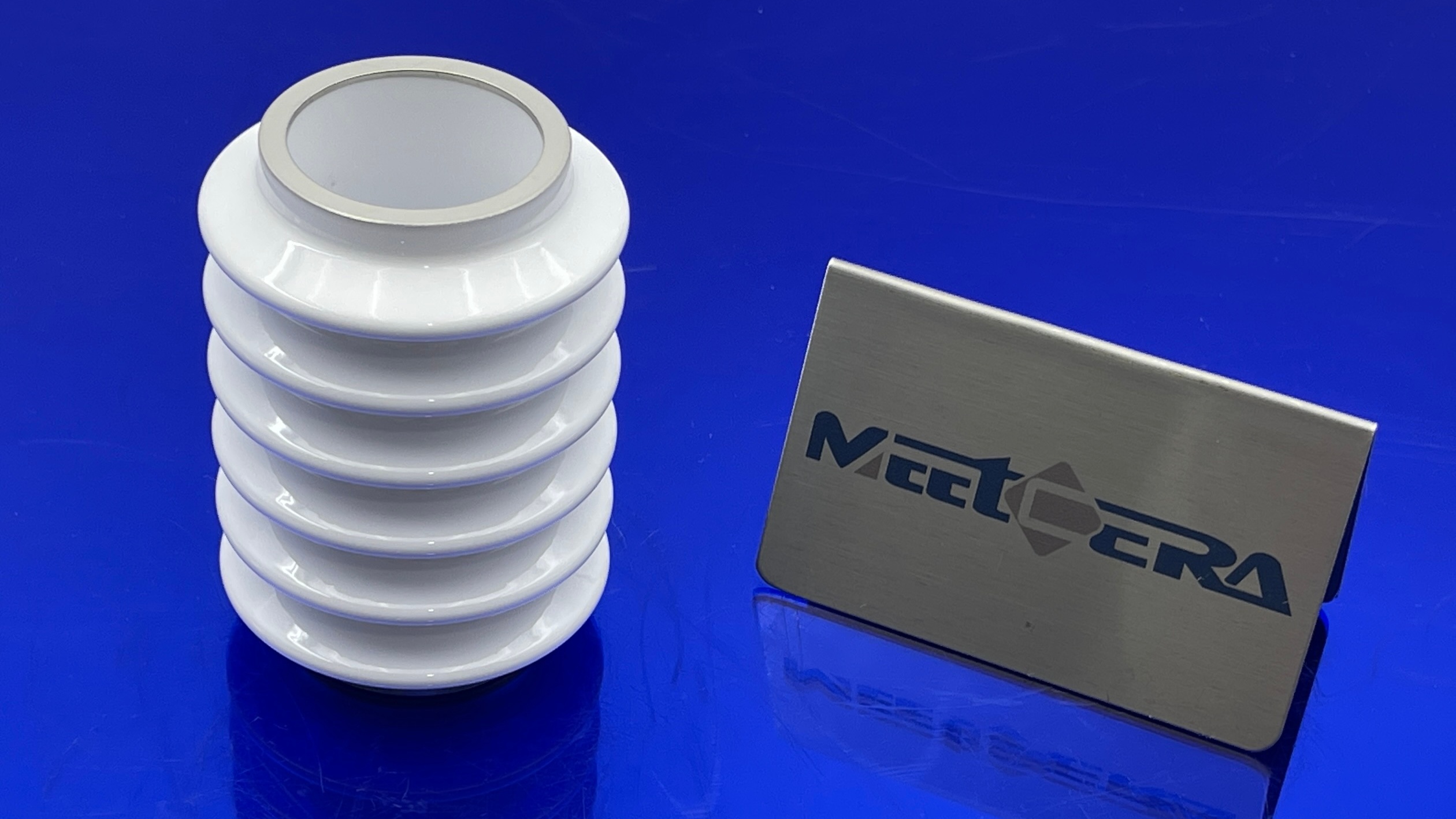

1. What are Metalized Ceramics?

What exactly are metalized ceramics, and what makes them so special for use in X-ray applications?

Metalized ceramics are engineered materials created by bonding ceramic materials to metal surfaces. This produces a strong, hermetic (airtight) seal that is crucial for many applications. A common technique involves moly-manganese metallization2, where a paste containing molybdenum and manganese is applied to the ceramic before firing at high temperatures.

Are they simply a mixture of metals and ceramic, or is it a more complex process? No, it's a strategic combination achieved through a sophisticated manufacturing process involving precise temperature control and material composition to ensure a robust and reliable bond.

2. What is the Role of Metalized Ceramics in X-Ray Tubes?

Why are metalized ceramics so frequently employed in the construction of X-ray tubes, and what specific functions do they fulfill?

Metalized ceramics are fundamental for connecting ceramic insulators to metal components within X-ray tubes. This ensures the creation of vacuum-tight seals to maintain the internal vacuum essential for proper X-ray generation. Furthermore, they provide reliable high-voltage (HV) insulation, preventing electrical arcing and ensuring safe operation.

Is their primary contribution limited to electrical insulation, or do they serve additional critical roles? No, beyond electrical insulation, they also play a vital role in maintaining the vacuum integrity of the tube, providing mechanical support to internal components, and facilitating reliable connections between different parts of the assembly.

3. How Do Metalized Ceramics Improve Insulation Performance?

How do metalized ceramics specifically enhance insulation capabilities in X-ray devices, and what are the underlying mechanisms?

Metalized ceramics provide exceptionally high dielectric strength3, which is the ability of a material to withstand an electric field without breaking down and conducting current. This characteristic is critical for preventing electrical arcing and short circuits at the high voltages used in X-ray tubes. Their high surface resistivity also minimizes leakage current, further enhancing insulation performance.

Are metalized ceramics merely good insulators, or do they possess superior qualities compared to traditional materials? They offer substantial advantages over traditional insulating materials due to their combination of high dielectric strength, resistance to thermal degradation, and ability to form hermetic seals, making them ideal for high-voltage applications.

4. How Do Metalized Ceramics4 Enhance Vacuum Reliability?

How do metalized ceramics contribute to maintaining a strong and stable vacuum inside X-ray tubes, ensuring optimal X-ray production?

Metalized ceramics are instrumental in creating hermetic, vacuum-tight seals between different components of the X-ray tube. These seals effectively prevent gas leakage into the tube, which can degrade the vacuum and reduce X-ray output. By maintaining a consistent vacuum level, metalized ceramics ensure stable and predictable X-ray generation.

Are they simply sealing agents, or do they actively work to prevent vacuum degradation over time? They are active in preventing long term degradation over time by being hermetic in nature.

5. How Do Metalized Ceramics Improve Structural Bonding?

What specific advantages do metalized ceramics offer concerning the structural integrity and mechanical stability within X-ray tubes?

Metalized ceramics facilitate strong, reliable bonds with other metal components within the X-ray tube assembly. This creates robust mechanical joints that can withstand the significant thermal and mechanical stresses encountered during operation. The strong bonds ensure stable assembly and prevent component failure, contributing to the overall reliability of the X-ray tube.

Are they brittle, or could they be considered durable? They are strong and durable; but they could break with a very heavy amount of force.

6. How Do Metalized Ceramics Improve High-Voltage Endurance?

How do metalized ceramics withstand the challenges of continuous high-voltage operation within X-ray tubes, ensuring long-term performance?

Metalized ceramics demonstrate exceptional resistance to electrical arcing, a phenomenon that can damage insulating materials and lead to equipment failure. The material is specifically designed to prevent surface breakdown and withstand the high voltage stresses present in X-ray tubes, ensuring long-term reliability, especially in continuous high-kV environment.

Can you relay a way to implement those ceramics? These can be helpful by minimizing downtime, and improves overall system performance.

7. How Do Metalized Ceramics Improve Long-Term Stability?

What characteristics make metalized ceramics a reliable choice for long-term use in X-ray tubes, particularly in harsh operating conditions?

Metalized ceramics exhibit remarkable resistance to degradation caused by X-ray radiation exposure5, maintaining their material properties over extended periods. They provide the tubes stable performance even in harsh conditions or environments.

Is there significant maintainence costs for these? The maintenance is extremely reduced.

8. What are the Key Advantages for Manufacturers and End Users?

What are benefits do metalized ceramics bring to both X-ray tube makers and its consumers?

Manufacturers benefit from improved production yields because of more reliable components and assembly processes. End users experience increased equipment reliability, resulting in reduced downtime, lower maintenance costs, and more stable performance. All benefits result in a longer equipment lifespan.

Is the total result good for business? Yes, the result is advantageous.

| Benefit | Manufacturer | End User |

|---|---|---|

| Production | Increased yield, decreased scrap, simplified assembly. | Higher equipment uptime, fewer interruptions in operation. |

| Costs | Reduced rework, fewer component failures during manufacturing. | Lower maintainence, less replacements and lower lifecycle costs. |

| Performance | Consistent component performance, higher reliability of end product | Stable and repeatable X-ray output, more accurate and reliable results. |

| Longevity | Extends component lifespans. | Reduces tube degradation. |

9. Practical Examples and Application Scenarios

In what real-world applications are metalized ceramics commonly found within X-ray technology?

Metalized ceramics are essential in numerous X-ray applications, including Computed Tomography (CT) scanners for medical imaging, industrial radiography for non-destructive testing6 of materials, analytical instruments, medical, industrial equipment, and even security screening systems that use X-ray technology.

How far can the practical application of the material be used in the real world? The material can be used for security, industrial, and medical use.

10. How We Connect Metalized Ceramics to Metal

Elaborate on the process of connecting metalized ceramics to metal components, and what makes it a critical aspect of X-ray tube construction.

You can process a metalized layer on certain surfaces. This layer enables the brazing or soldering.

How much labor is involved? Brazing and metallization is heavy in manufacturing labor.

Creating a good ceramic-to-metal joint is a whole field of engineering itself. The materials expand at different rates with heat. The joining method must handle this difference without creating too much stress. Metallization and brazing, when done right, solve this.

11. Conclusion

Metalized ceramics are indispensable for reliable X-ray tubes as they offer a unique combination and essential structural, electrical, thermal, and mechanical properties. Partnering with experienced manufacturers ensures that you're using the best components, leading to reduced downtime, improved performance, and ultimately a better return on investment. Investing in high-quality metalized ceramics is integral for the success and longevity of your X-ray equipment.

-

Understand the critical role of vacuum sealing in maintaining X-ray tube performance. ↩

-

Discover the process of moly-manganese metallization and its significance in ceramics. ↩

-

Find out how dielectric strength prevents electrical arcing in high-voltage applications. ↩

-

Explore how Metalized Ceramics enhance insulation and vacuum reliability in X-ray tubes. ↩

-

Explore the impact of X-ray radiation on the materials used in X-ray technology. ↩

-

Learn about the importance of metalized ceramics in industrial radiography applications. ↩