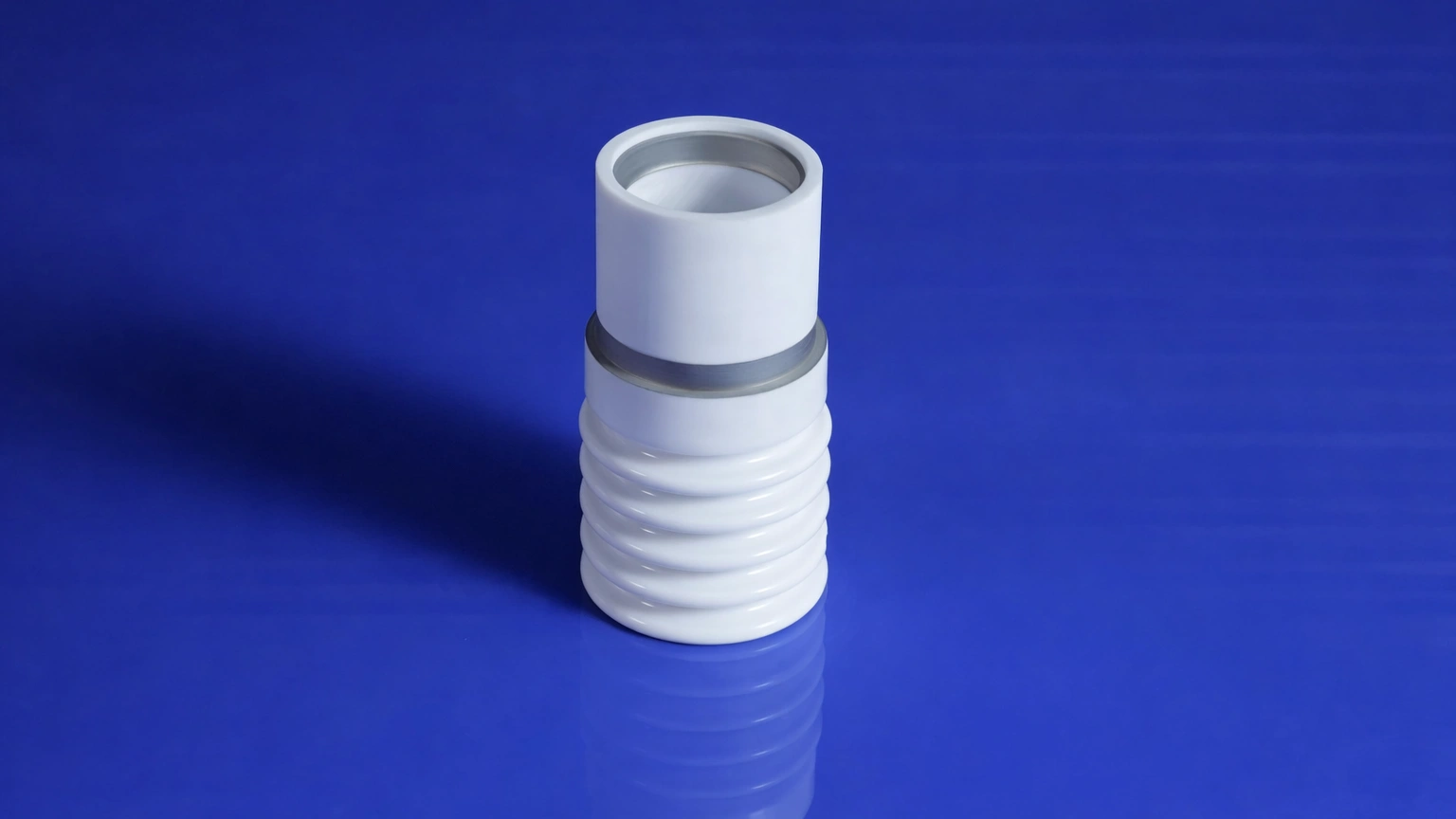

What Is a Metal Ceramic X-Ray Tube?

A metal ceramic X-ray tube uses a metal envelope + ceramic insulators instead of traditional all-glass design. This delivers much better durability, superior heat dissipation, lower arcing risk, and significantly longer service life — making it the go-to choice for CT scanners, industrial CT, high-power NDT, security inspection, and similar demanding applications.

1.Metal Ceramic vs Traditional Glass: Quick Comparison

| Feature | Glass Tube | Metal Ceramic Tube | Key Advantage |

|---|---|---|---|

| Envelope | All glass | Metal + ceramic | Higher strength & durability |

| Heat Capacity | Limited | 4–30+ MHU | Longer/higher power operation |

| Arcing Risk | High | Very low | Superior reliability |

| Lifespan (heavy use) | 3–5 years | 5–10+ years (CT models) | Fewer replacements |

| Off-Focus Radiation | Higher | Lower | Better image quality |

| Compactness | Larger | More compact | Fits modern high-speed systems |

(Based on Philips MRC, Siemens Straton, and Comet technical data)

2.How It Works & Why Thermal Management Matters

Core process is unchanged:

-Heated filament emits electrons

-High voltage accelerates them to tungsten anode

-Impact generates X-rays

Metal ceramic excels here: metal envelope + advanced bearings (e.g. liquid metal in premium models) enable far better heat spreading and cooling — directly translating to higher power, faster scans, and longer tube life.

3.Main Types in Use Today

- Conventional rotating anode tubes — Industrial NDT (100–450 kV), security, mid-range CT

- Philips MRC Series — Liquid metal bearing, 7–30 MHU, 800k–1.5M+ scan seconds lifespan; standard in Philips CT (Brilliance/Ingenuity)

- Siemens Straton Series — Entire tube rotates, near-zero heat storage, ultra-fast cooling; used in high-speed Siemens SOMATOM systems

- Micro-focus / high-capacity industrial

4.Realistic Lifespan & Maintenance Essentials

- Medical CT tubes (MRC/Straton): 5–10 years / 800k–1.5M+ scan seconds

- Industrial tubes: 3–7 years

- Micro-focus: 1–4 years

7 key maintenance rules to reach or exceed these numbers:

(1). Always do warm-up/seasoning

(2). Follow exposure & cooling charts strictly

(3).Use conservative mA settings

(4). Minimize rotor start/stop cycles

(5). Keep cooling system (oil/water/air) in top condition

(6). Monitor output & arcing events

(7). Update firmware for better heat algorithms

Replace when you see: reduced output, more noise/artifacts, frequent arcing, rotor noise, overheating, vacuum issues, or focal drift.

5.How to Choose the Right One

- Confirm exact system/model compatibility

- Weigh OEM vs quality refurbished/third-party

- Check HU capacity, cooling, focal spot specs

- Calculate total cost of ownership (lifespan + service)

For custom metalized ceramics, tube specs, or replacement help — check these:

Questions about your specific application? Just let me know!