What Are the Components of an X-Ray Tube?

Simply put, the X-ray tube is the true “heart” of every hospital X-ray machine, CT scanner, and dental imaging system. It looks like a big sealed light bulb, but inside it turns electricity into the invisible X-rays that let doctors see your bones.

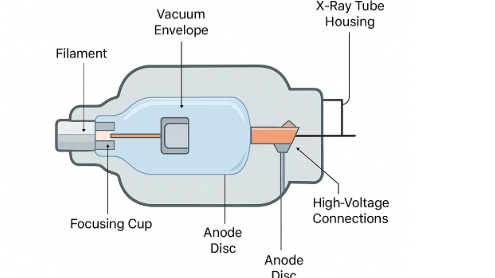

A complete modern medical X-ray tube consists of just these 6 major components:

- Cathode – produces electrons

- Anode – electrons crash here to create X-rays

- High-vacuum glass or metal-ceramic envelope

- Rotating mechanism1 (99 % of today’s tubes use a rotating anode)

- Cooling system2 – prevents meltdown in seconds

- Protective housing3 – the thick lead shield that stops radiation leaks

This article uses the simplest language + clear diagrams to help medical students, radiographers, service engineers, or anyone curious fully understand every part from scratch.

1.How Does an X-Ray Tube Actually Make X-Rays?

- The cathode filament is heated red-hot → electrons “boil off” like crazy

- 80–150 kV high voltage is applied → electrons are yanked toward the anode at ~1/3 the speed of light

- Electrons slam into the tungsten target and suddenly “hit the brakes” → their kinetic energy instantly turns into X-ray photons (called Bremsstrahlung radiation)

- X-rays shoot out through a tiny side window (beryllium window), pass through the patient, and create the image on the detector

That’s literally all it takes — four steps from electricity to X-ray!

2.The 6 Core Components Explained

(1). Cathode4 – The “Electron Gun”

- Core part: tungsten filament (same material as old incandescent bulbs)

- Heats to ~2400 °C in 2 seconds and shakes electrons loose

- Focusing cup shapes the electrons into a tight, straight beam

- Most tubes have dual focal spots: large for chest, small for sharp extremity images

- This filament is the #1 thing that fails — it slowly evaporates and finally snaps

(2).Anode5 – The “Target Disc”

- 99 % of medical tubes use a rotating anode: a tungsten-rhenium disc spinning 9,000–10,000 RPM

- Impact temperature hits 2500 °C instantly — without rotation it would melt a pit in one second

- Rotation spreads the heat over a ring track, letting the tube handle hundreds of kilowatts

- Spinning is powered by an internal rotor + external stator coils (exactly like an electric fan motor)

(3). Vacuum Envelope (Glass or Metal-Ceramic)

- Vacuum is millions of times better than outer space

- Even a tiny bit of air would scatter electrons and burn out the filament immediately

- Older tubes used glass (you could see the glowing filament); modern CT tubes use stronger metal-ceramic

(4). Beryllium Window – The “X-Ray Escape Door”

- Regular glass would absorb most low-energy X-rays

- A 0.1–1 mm thin beryllium window lets almost all X-rays out while keeping vacuum sealed

- No beryllium window = dark, useless images

(5).Cooling System + Insulating Oil

- 99 % of input energy becomes heat

- The tube is submerged in circulating transformer oil that carries heat away

- High-end CT tubes add water or forced-air cooling

- The oil also provides high-voltage insulation to prevent arcing

(6). Protective Housing – The “Thick Lead Tank”

- Entire insert + oil is sealed inside a lead-lined metal case

- Blocks stray radiation in every direction except the beryllium window

- Includes an expansion bellows so oil can expand and contract safely

One-sentence memory trick:

Red-hot filament spits electrons → high voltage accelerates → smash into spinning tungsten disc → sudden stop makes X-rays → escape through beryllium window → safely contained inside a lead tank.

Frequently Asked Questions (FAQ)

Q1: Which part of an X-ray tube6 fails most often?

A: The tungsten filament in the cathode. It evaporates over time and eventually breaks — 90 % of tube replacements are because the filament died.

Q2: Why can a rotating anode handle tens of times more power than a stationary one?

A: Because the heat is spread over a moving ring instead of burning one tiny spot.

Q3: How thick is the beryllium window?

A: Regular diagnostic tubes: 0.1–0.5 mm

CT tubes: 0.5–1 mm

Mammography tubes: as thin as 0.05–0.1 mm

Q4: How can you tell if an X-ray tube is leaking oil?

A: Oil stains on the housing, overheating alarms, crackling/arcing sounds during exposure, or a collapsed or overly swollen expansion bellows. Stop using it immediately!

3.conclusion

You now know the X-ray tube’s 6 key parts:

Cathode ・ Anode (rotating) ・ Vacuum envelope ・ Rotation system ・ Cooling ・ Protective housing.

Quick flow: Hot filament → electrons → smash spinning target → X-rays out through beryllium window → safely shielded.

Master this → operate better, spot failures faster (filament or oil issues most common).

Want deeper details on any part or brand? Email me on the right — happy to send diagrams!

Looking forward to your message!

-

Find out how rotation enhances the performance and longevity of X-ray tubes. ↩

-

Understand how cooling systems prevent overheating and ensure safe operation. ↩

-

Discover how protective housing safeguards against radiation exposure. ↩

-

Learn about the cathode's role in producing electrons for X-ray generation. ↩

-

Discover how the anode transforms electron energy into X-rays. ↩

-

Understanding the X-ray tube is crucial for grasping medical imaging technology. ↩