is a unique high-performance engineering ceramic that combines exceptional thermal, electrical, mechanical, and optical properties. It is the only oxide ceramic that simultaneously offers this outstanding combination of characteristics.

Key Performance Advantages:

- Extremely high thermal conductivity: 250–325 W/m·K at room temperature — over 9 times that of alumina (Al₂O₃), 1.5–1.8 times that of aluminum nitride (AlN), surpassed only by diamond.

- Excellent electrical insulation: Low dielectric constant (≈6.7), very low loss, and volume resistivity >10¹⁵ Ω·cm — ideal for high-frequency and high-power applications.

- Superior chemical stability and lightweight design: Lower density than Al₂O₃ and AlN, with high stiffness and good thermal shock resistance.

Comparison with Common Alternatives:

- Much higher thermal conductivity than Al₂O₃ and AlN

- Lower dielectric constant

- Lighter weight with superior overall performance

Typical Applications:

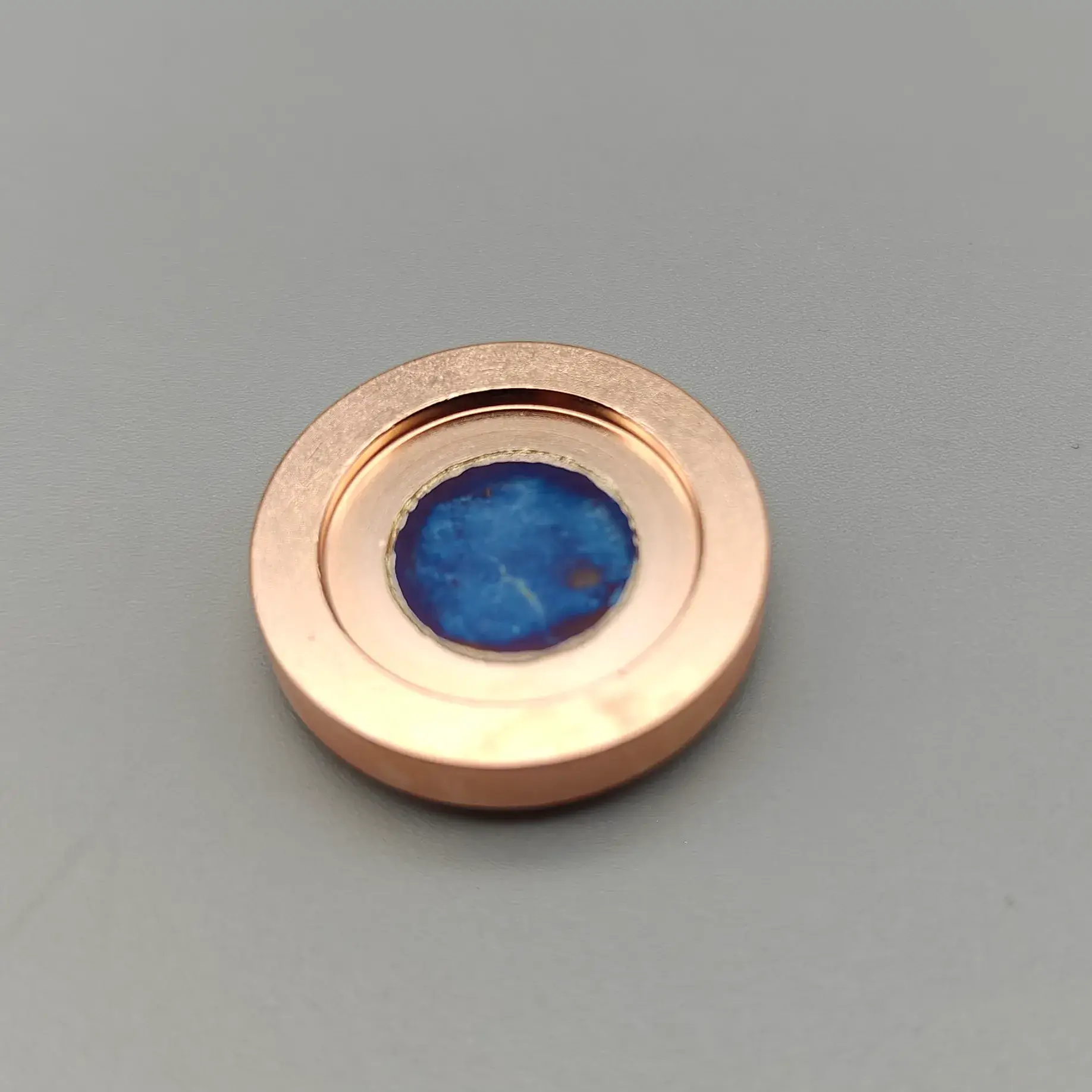

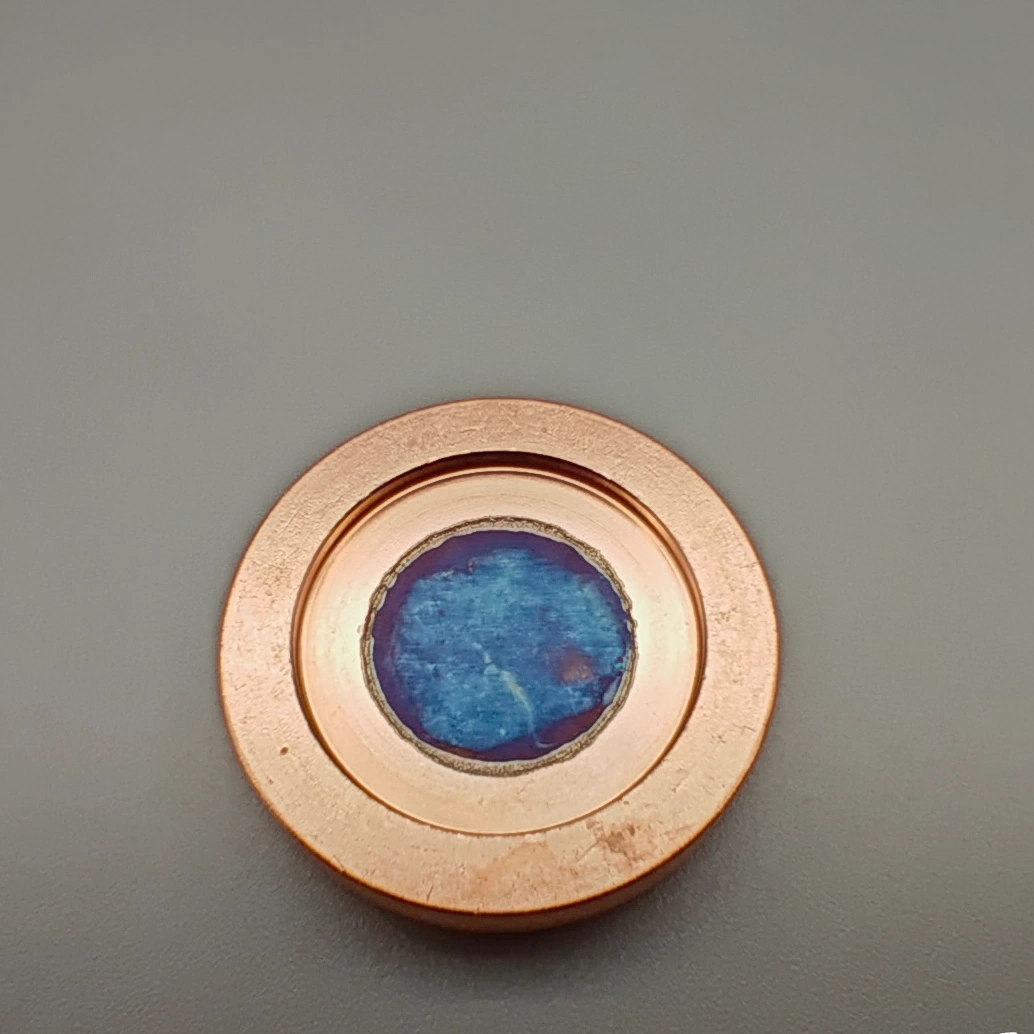

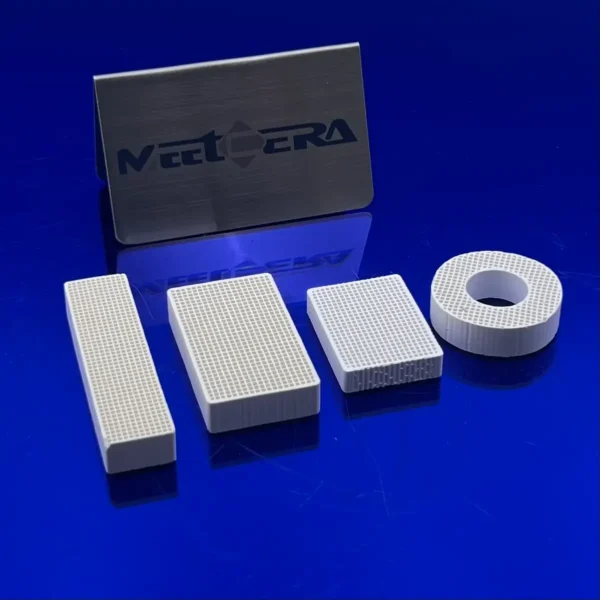

- Heat sinks, insulating washers, and substrates for high-power electronics

- RF/microwave components (waveguides, radomes)

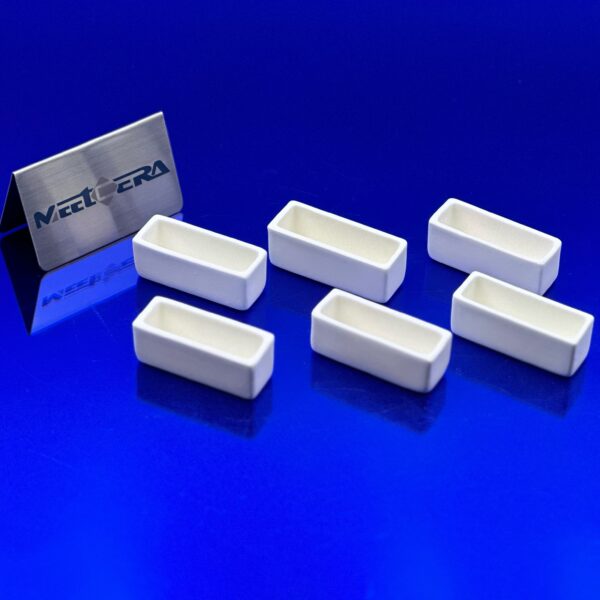

- Nuclear technology (neutron moderators, high-temperature crucibles)

- Laser devices, vacuum tubes, and emerging fields like quantum computing thermal management

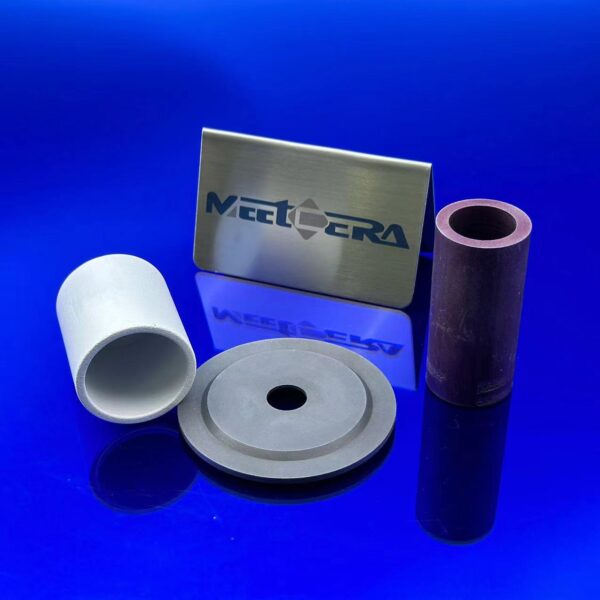

Supply Information: Meetcera suppliers offer high-purity (≥99.5%) BeO ceramic products, including sheets, rods, crucibles, and custom parts for research and industry.

Safety Note: Fully sintered BeO ceramics are safe and non-toxic under normal use. Avoid dust during machining and follow safety protocols.

BeO is the preferred material for applications demanding electrical insulation + extreme thermal conductivity + high-temperature stability.

Typical Properties of High-Purity BeO Ceramics (99.5%+)

| Property | Units | Typical Value (99.5% BeO) | Notes / Comparison |

|---|---|---|---|

| Composition | % | ≥99.5 BeO | High-purity grade |

| Color | - | White to light grey | |

| Density | g/cm³ | 2.85–2.90 | ~75% of Al₂O₃ density |

| Thermal Conductivity (at RT) | W/m·K | 250–325 | 9–10× Al₂O₃; 1.5–1.8× AlN |

| Coefficient of Thermal Expansion (RT to 1000°C) | 10⁻⁶/°C | 9 | |

| Specific Heat | cal/g°C | 0.25 | |

| Flexural Strength | MPa | 200–260 | |

| Hardness | Rockwell 45N | 60 | |

| Dielectric Constant (1 MHz, RT) | - | ≈6.7 | Lower than Al₂O₃ (~9.8) and AlN (~8.5) |

| Dissipation Factor (1 MHz, RT) | - | 0.0004 | Very low loss |

| Volume Resistivity (RT) | Ω·cm | >10¹⁵ | Excellent insulation |

| Dielectric Strength | V/mil | ~230 |

Frequently Asked Questions (FAQ)

1. Is BeO ceramic toxic?

Finished sintered BeO is safe for normal handling and use. Toxicity risk comes only from inhalable dust during machining. Use proper ventilation, wet processing, and respirators to eliminate risks.

2. Why choose BeO over aluminum nitride (AlN)?

BeO provides 50%–80% higher thermal conductivity, lower dielectric constant, and better stability in oxidizing environments, while being lighter. AlN is easier to machine and non-toxic, but BeO outperforms in extreme thermal applications.

3. Is BeO expensive, and can it be fully replaced?

BeO is more costly due to material scarcity and safety requirements, but its unique performance often justifies the price in high-power designs. No single alternative currently matches its full combination of properties.

For additional questions, feel free to ask!