What Are the Different Types of Vacuum Feedthroughs?

Vacuum feedthroughs are critical components in high-vacuum (HV) and ultra-high vacuum (UHV) systems. They allow the transfer of electricity, fluids, gases, or mechanical motion from the atmospheric side to the vacuum side while maintaining a hermetic seal.

Understanding the different types of vacuum feedthroughs helps you select the right solution for applications such as semiconductor manufacturing, thin-film deposition, research chambers, and cryogenic systems.

This guide explores the main categories of vacuum feedthroughs and their subtypes.

1. Electrical Feedthroughs

Electrical feedthroughs transmit electrical power or signals into a vacuum environment. They vary by voltage, current, and signal type.

| Subtype | Typical Applications | Features |

|---|---|---|

| High-Current Power Feedthroughs (Learn more) | Deposition sources, sputtering targets, substrate heating | Low voltage (<50 V) but high current (hundreds–thousands of amps); optional water cooling for high thermal loads |

| Thermocouple Feedthroughs (Learn more) | Temperature monitoring in vacuum chambers | Accurate temperature measurement; maintains vacuum integrity |

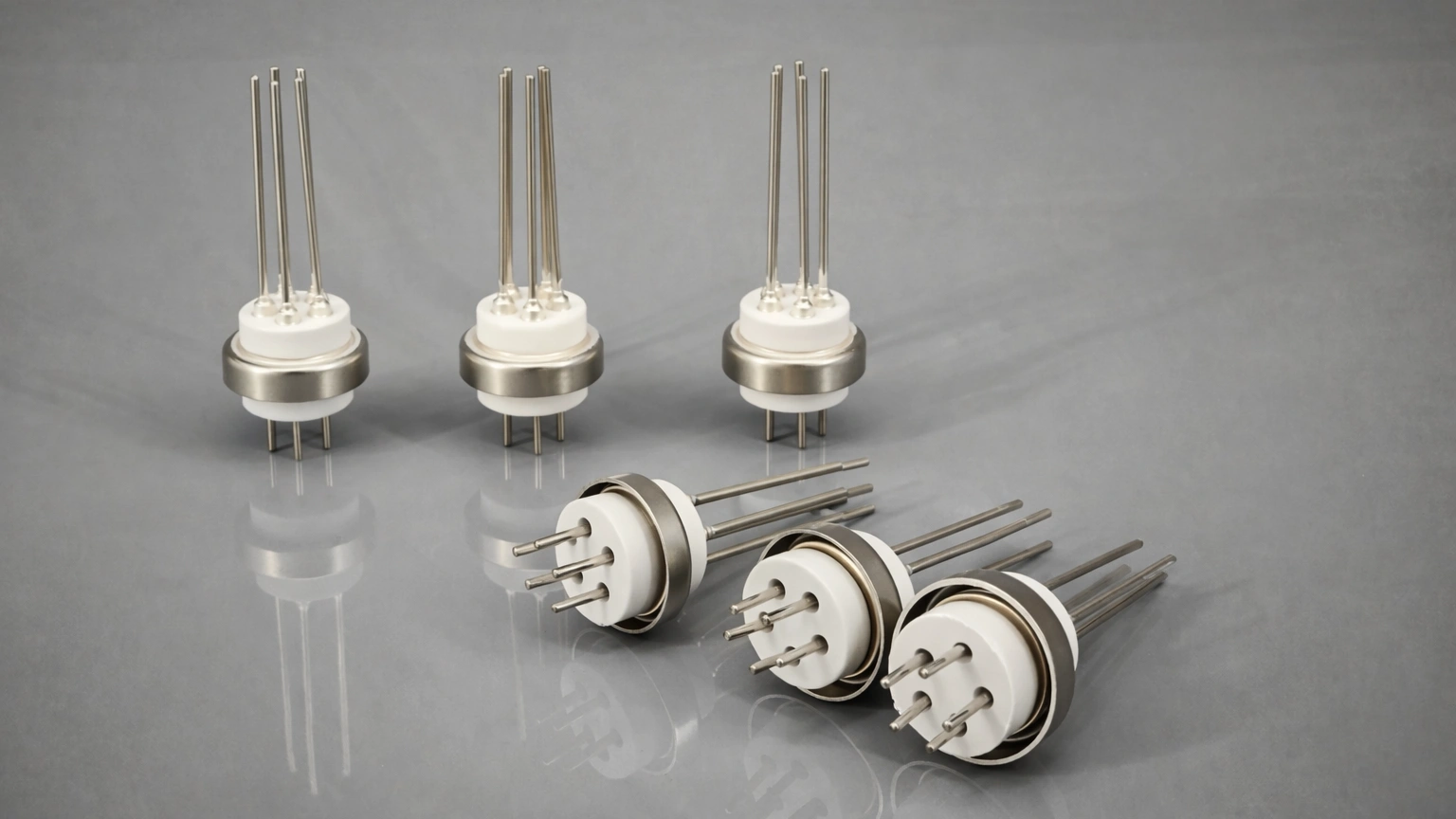

| Multipin Feedthroughs (Learn more) | Instrumentation, sensors, control signals | Multiple electrical connections in a single unit |

| Coaxial Feedthroughs | High-frequency signal transmission | Shielded conductors; minimal interference |

| RF Feedthroughs | RF plasma, deposition systems | Optimized for radio-frequency power; low signal loss |

2. Fluid and Gas Feedthroughs

Fluid and gas feedthroughs allow liquids or gases into a vacuum chamber for cooling, purging, or process gas delivery.

| Subtype | Applications | Features |

|---|---|---|

| Standard Fluid/Gas Feedthroughs (Learn more) | General cooling or gas delivery | Stainless steel tubing, VCR or Swagelok fittings, high bakeout capability |

| Cryogenic Feedthroughs | Liquid nitrogen (LN₂), liquid helium (LHe) | Thermal insulation shields to prevent condensation; suitable for UHV cryogenic applications |

3. Rotary Motion Feedthroughs

Rotary feedthroughs transmit rotational motion into the vacuum chamber. Common uses include sample manipulation, beam steering, or rotating sputtering targets.

| Seal Type | Applications | Features |

|---|---|---|

| Elastomer-Sealed Rotary Feedthroughs | Lower RPM applications | O-ring seals; serviceable; cost-effective; good torque at moderate speeds |

| Ferro-Sealed (Ferrofluid) Rotary Feedthroughs | High RPM / high torque | Magnetic ferrofluid seals; minimal particles; ideal for UHV and clean environments |

4. Transition Feedthroughs

Transition feedthroughs, or baseplate feedthroughs, provide adaptable interfaces for vacuum chamber ports.

| Type | Applications | Features |

|---|---|---|

| Flange-Based Transition Feedthroughs (Learn more) | Mounting gauges, sensors, or additional components | Compatible with standard flanges: ConFlat (CF), ISO-QF (KF) |

| Fitting-Based Transition Feedthroughs | Flexible system connections | Female NPT threads, quick disconnects, blank plugs |

5. Key Considerations for Choosing Vacuum Feedthroughs

When selecting a vacuum feedthrough, consider:

- Type of transfer (electrical, fluid/gas, motion, or transition)

- Vacuum level (HV vs. UHV)

- Operating temperature and bakeout requirements

- Electrical current and voltage ratings

- Material compatibility

- Flange and connection standards

Choosing the right feedthrough ensures system efficiency, reliability, and leak-free operation. For specialized applications, consult with vacuum system experts.

6. Frequently Asked Questions (FAQ)

Q: What is the main purpose of a vacuum feedthrough?

A: To maintain a hermetic seal while allowing power, signals, fluids, gases, or motion between atmospheric and vacuum environments.

Q: Can vacuum feedthroughs be used in cryogenic applications?

A: Yes. Specialized cryogenic feedthroughs support low-temperature fluids like liquid nitrogen, with insulation to minimize heat leakage.

7. Conclusion & Next Steps

Selecting the right vacuum feedthrough ensures reliable and efficient operation of your vacuum system. Explore high-quality feedthroughs tailored to your applications and consult qualified suppliers for:

- Custom solutions

- Detailed specifications

- Technical support for HV, UHV, or cryogenic systems

Optimize your vacuum system today by choosing the right feedthrough technology for your application.