Why Ceramic-to-Metal Seals Excel in Vacuum Feedthroughs?

A single tiny leak in a semiconductor production line or particle accelerator can cause massive financial losses or invalidate critical experiments. These risks highlight the need for absolute reliability in vacuum systems.

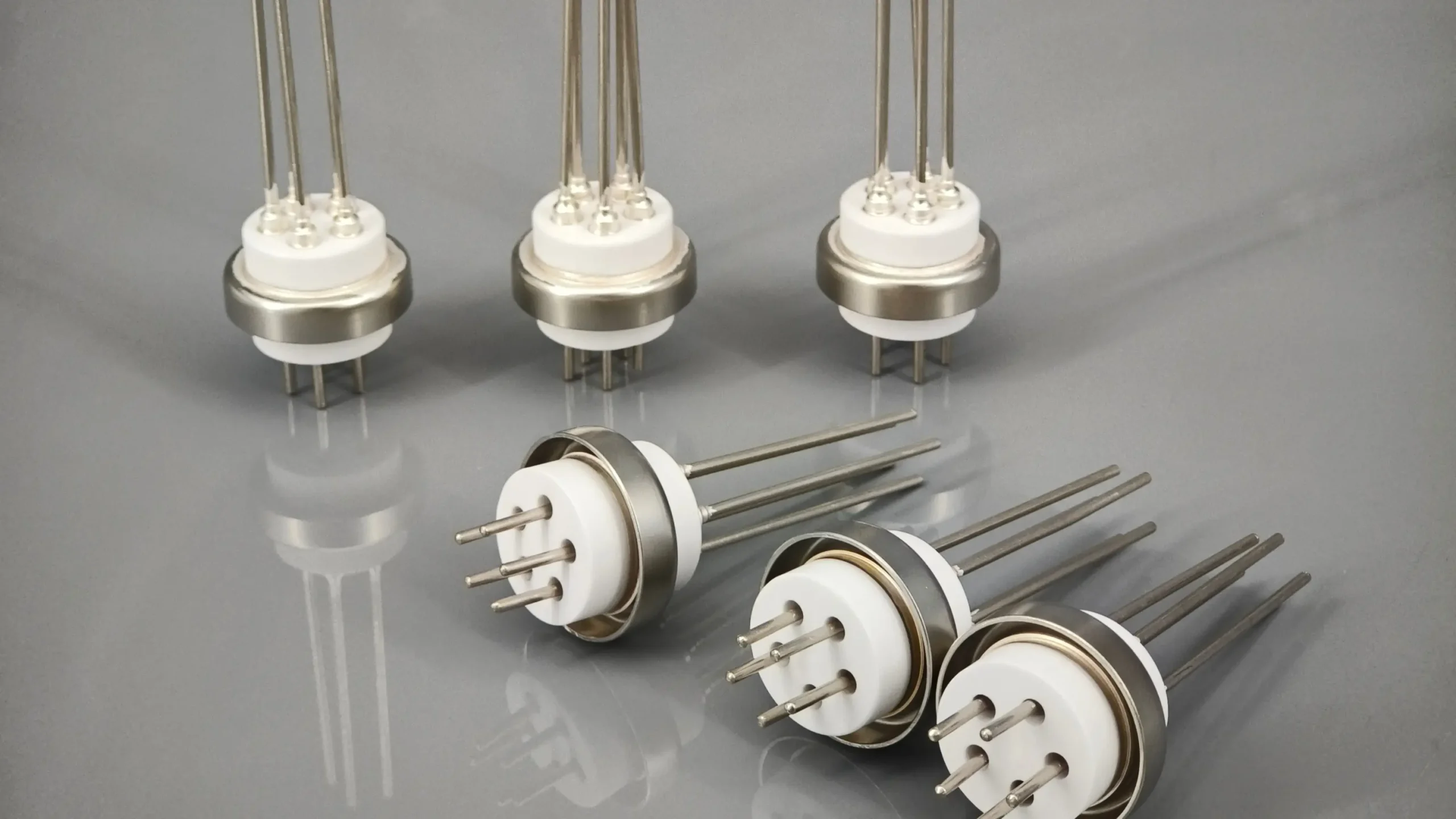

Vacuum feedthroughs act as a secure “gate,” allowing power, signals, or fluids to enter a vacuum chamber without compromising the vacuum. Among all sealing technologies, ceramic-to-metal seals are widely recognized as the industry gold standard due to their superior performance and reliability.

For high-vacuum and ultra-high-vacuum definitions, see the standards published by the

European Organization for Nuclear Research (CERN)

1. What Is a Ceramic-to-Metal Seal?

Ceramic-to-metal seals permanently bond high-purity ceramics (e.g., alumina Al₂O₃) with metals (e.g., stainless steel, titanium, or Kovar) using brazing or metallization.

The key lies in precisely matched thermal expansion coefficients, preventing cracks or leaks during temperature changes. This fusion combines the ceramic’s excellent insulation and heat resistance with the metal’s strength and conductivity, creating a permanent, outgassing-free seal.

NASA has extensively documented the use of ceramic-to-metal seals in space and vacuum environments:

NASA – Materials and Processes for Space Vacuum Systems

2. Four Key Advantages of Ceramic-to-Metal Seals

Ceramic-to-metal seals excel thanks to:

- Ultimate hermeticity: Leak rates as low as 10⁻¹⁰ mbar·l/s, ideal for HV and UHV applications.

- Extreme temperature resistance: From -269°C (liquid helium) to over 450°C (bakeout-compatible), with strong thermal shock tolerance.

- Superior electrical performance: High dielectric strength for high voltage (10kV–100kV) and current feedthroughs.

- Long life and reliability: Inorganic materials with no aging or outgassing; supports repeated bakeout cycles.

Leading vacuum technology manufacturers also confirm these performance benchmarks, such as

Pfeiffer Vacuum – Vacuum Feedthrough Technology

3. Comparison with Other Sealing Technologies

| Parameter | Ceramic-to-Metal Seal | Glass-to-Metal Seal | Rubber/Epoxy Resin Seal |

|---|---|---|---|

| Vacuum Level | Ultra-High Vacuum (UHV) | High Vacuum (HV) | Medium / Low Vacuum |

| Temperature Range | -269°C to 450°C+ | -200°C to 300°C | <150°C |

| Mechanical Strength | High | Medium | Low |

| Service Life | Extremely long | Long | Short |

| Typical Cost | High | Medium | Low |

Ceramic-to-metal seals are unmatched where maximum reliability is required.

4. Typical Application Scenarios

- Semiconductor manufacturing: Plasma etching and coating equipment

- Scientific research: Particle accelerators, electron microscopes

- Aerospace: Space simulation chambers and satellite systems

- Medical devices: X-ray tubes and particle therapy equipment

5. Frequently Asked Questions (FAQ)

Q: Are ceramic-to-metal seals significantly more expensive?

A: Initial cost is higher due to precision manufacturing, but lifecycle cost is lower thanks to exceptional durability and minimal failures.

Q: What voltage and temperature extremes can they handle?

A: Typically 10kV–100kV and -269°C to over 450°C—perfect for cryogenic and high-temperature applications.

Q: Are there cheaper alternatives?

A: Glass-to-metal or epoxy seals work for less demanding applications, but for UHV or bakeout requirements, ceramic-to-metal is strongly recommended.

Need reliable vacuum feedthroughs? Contact us for expert advice and custom solutions.

Get Free Consultation & Quote

6. Conclusion: Choose the Gold Standard

Ceramic-to-metal seals have earned their position as the gold standard for high-reliability vacuum feedthroughs through unmatched hermeticity, extreme durability, and long-term stability.

For projects demanding uncompromised vacuum performance, choosing ceramic-to-metal seals is a smart, future-proof investment that protects against losses and supports innovation.

Ready to upgrade your vacuum system? Download our free selection guide today.

Download the Ceramic-to-Metal Feedthrough Guide

Reliability starts with the right seal—choose the gold standard.