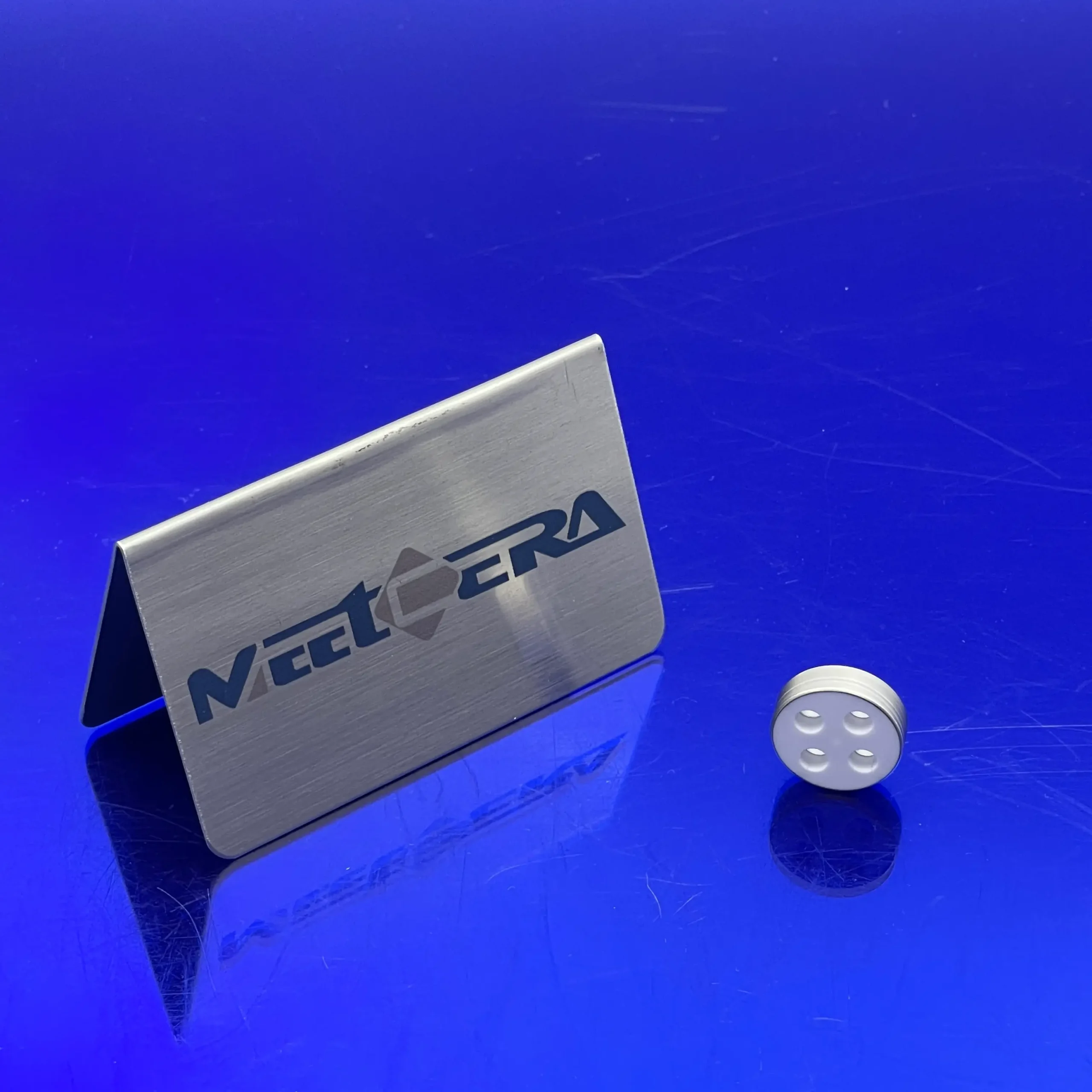

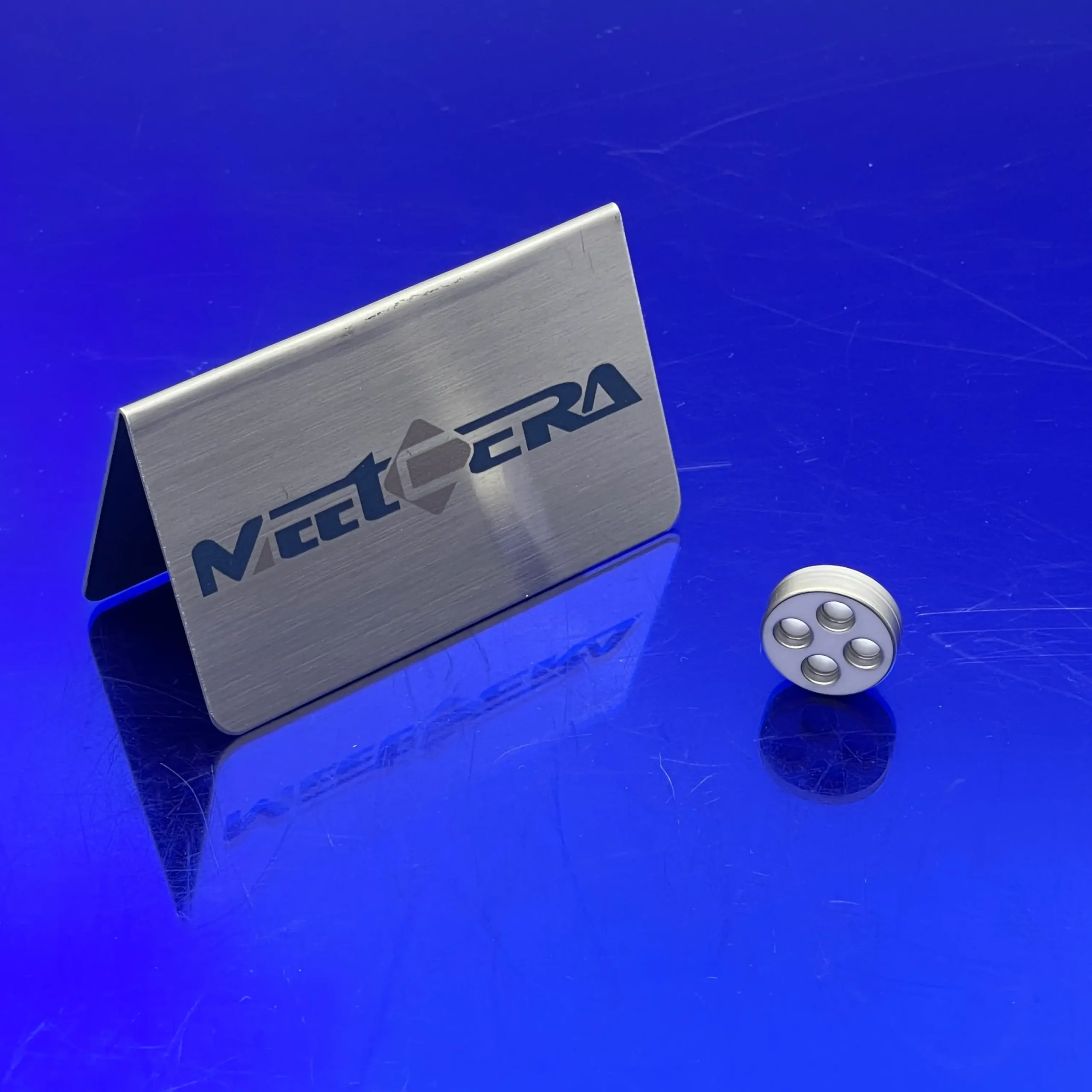

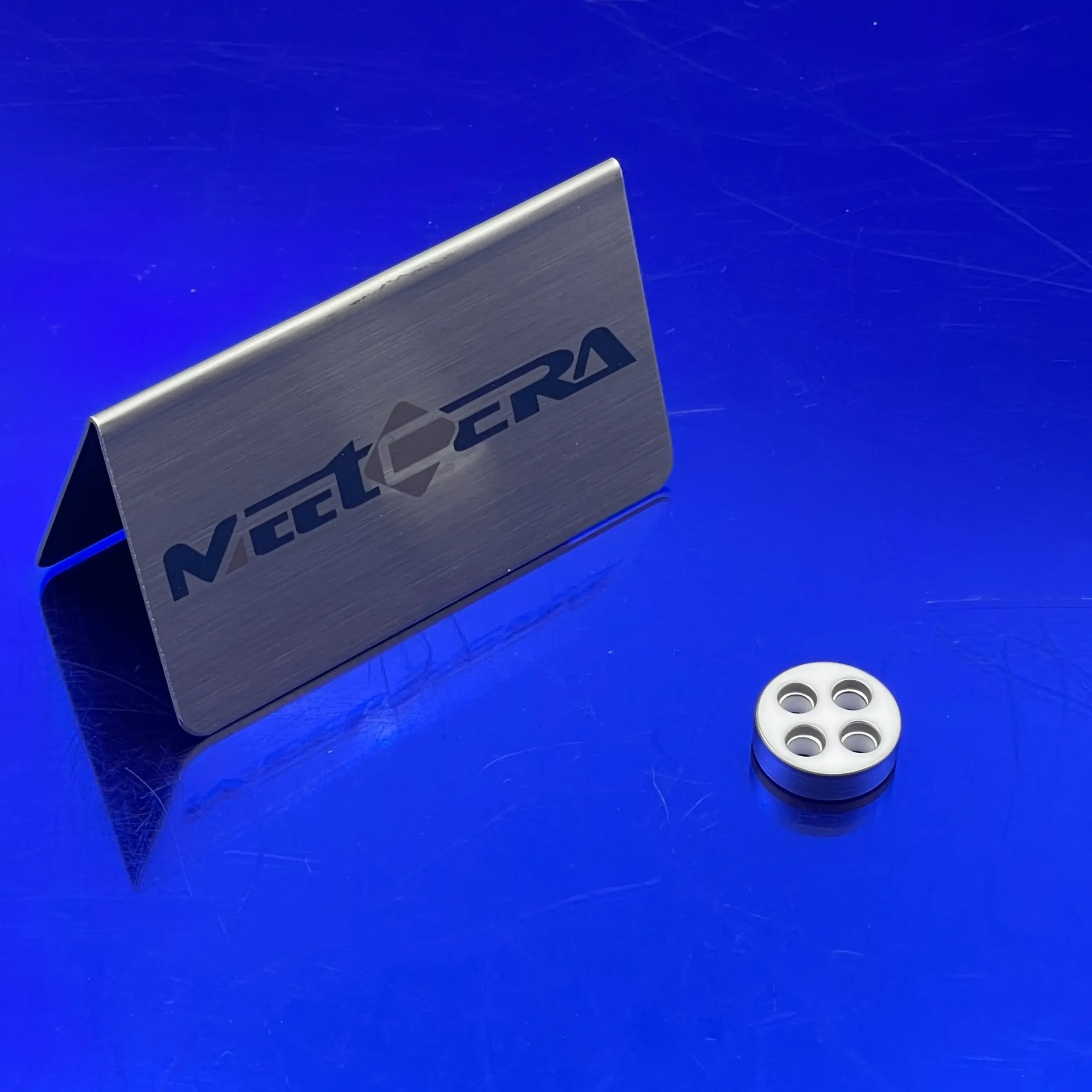

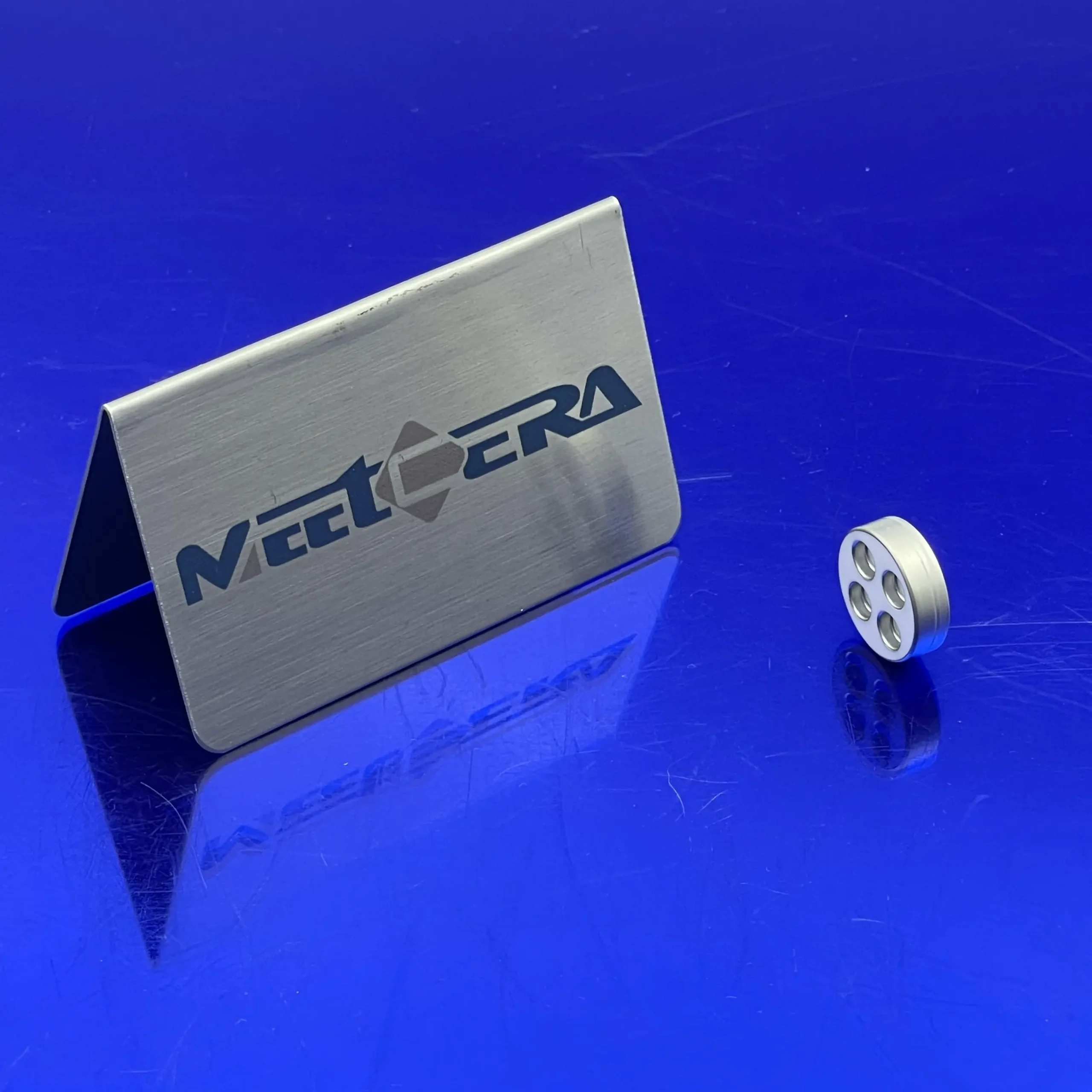

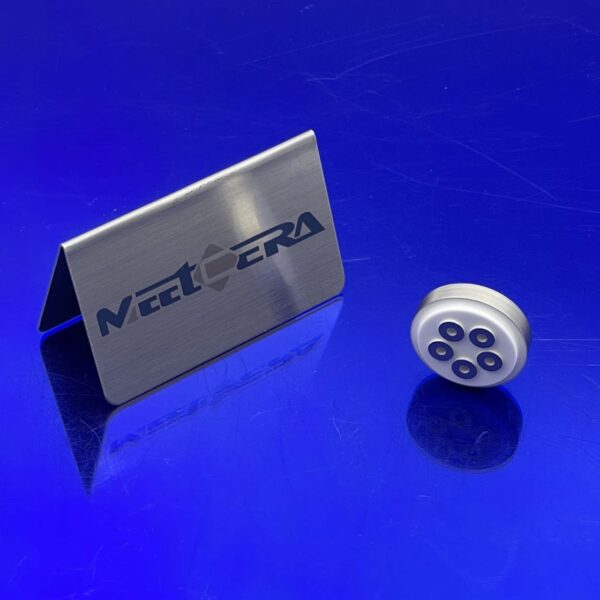

Metallized ceramic components

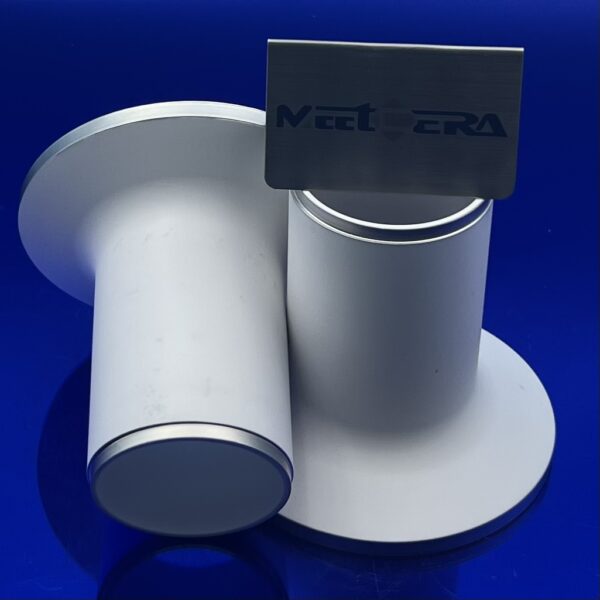

Product Name | Metallized Ceramics Componenets ( Tube, Ring, Plate, Rod, Substrate . . . ) |

Material | 95%, 96%, 99% Alumina (AL2O3) |

Color | White+Metal |

Coaing Layer | Mo/Mn |

Coaing thickness | 15-25um |

Plated Layer | Ni,Cu,Au,Etc |

Plating thickness | 8-10um |

Brand | MEETCERA |

Metallized Ceramics Applications:

- Ceramic Feed-through Insulators (for hermetic electrical pass-throughs)

- Ceramic Headers and High-Power Receptacles

- Insulating Discs, Rings, and Cylinders

- Precipitator Products and Power Switches

- Traveling Wave Tubes and Vacuum Interrupters

- Windows, Power Grid Tubes, and X-ray Tubes

These applications benefit from the components' ability to maintain integrity in harsh conditions, such as vacuum electronics, RF/microwave devices, sensors, and power modules

Metallized Ceramics Joining types:

- Ceramic + Mo/Mn Metallized + plating Ni

- Ceramic + Mo/Mn Metallized + plating Ag

- Ceramic + Mo/Mn Metallized + plating Au

- Ceramic + printing Ag

FAQ

Q.What is the purpose of metallization?

A.It enables strong brazing/soldering of ceramics to metals, creating reliable hermetic seals and electrical connections in high-vacuum or high-voltage applications.

Q.Why use Molybdenum-Manganese (Mo/Mn) as the base coating?

A.Mo/Mn provides excellent adhesion to alumina through high-temperature sintering, ensuring high bond strength and reliability.

Q. Do you offer custom metallized ceramics?

A.Yes, we produce fully customized components based on your drawings, samples, or specific requirements.

For detailed technical data, quotations, please contact us directly. Meetcera is committed to delivering innovative, high-quality solutions for your most challenging applications.