Alumina Ceramic Metallization Brazing: Mo-Mn Process & HV Cases

Alumina ceramic excels in insulation, high-temperature resistance, and corrosion resistance — perfect for high-voltage use.

Reliable ceramic-to-metal bonding is vital for high-voltage insulators.

The Mo-Mn metallization process is the industry standard for hermetic, high-strength joints.

This article explains the essentials of alumina ceramic metallization brazing, with focus on the Mo-Mn process and its use in high-voltage ceramic insulator metallization and high-voltage feedthrough MoMn.

Why Mo-Mn Is Preferred for High-Voltage Insulators

High-voltage insulators must handle tens of kV and severe thermal stress.

Mo-Mn creates a robust ceramic-metal interface with strong adhesion and matched thermal expansion.

Compared to active brazing or thin-film methods, Mo-Mn is cost-effective, mature, and highly reliable for sealing.

It prevents leakage and breakdown in feedthroughs, ensuring long-term stability.

See this ScienceDirect review on alumina-to-metal joining technologies.

Mo-Mn Metallization Process Overview

Slurry Coating

Mo-Mn slurry (molybdenum + manganese + binder) is applied evenly by screen printing or spraying. Thickness must be uniform.

High-Temperature Sintering

Performed in hydrogen/forming gas at 1300–1500°C.

Manganese forms a glassy phase for chemical bonding; molybdenum ensures conductivity.

Result: 10–30 μm metallized layer.

Microstructure details are covered in this ScienceDirect study on metallized ceramics.

Nickel Plating

A 3–8 μm nickel layer is electroplated or electroless-plated to improve wettability for brazing.

Brazing with AgCu Solder & Key Parameters

Eutectic AgCu solder (Ag72-Cu28, melting ~779°C) is standard.

Brazing occurs in vacuum at 810–850°C peak, 5–15 min hold, 5–10°C/min ramp.

Nickel layer ensures excellent wetting and dense joints.

This delivers high hermeticity and strength in high-voltage feedthrough MoMn applications.

Brazing & hermeticity research (Mo-Mn included) is detailed in this Frontiers article on ceramic-metal joints.

Common Defects and Prevention

Peeling/Delamination — caused by contamination, over-sintering, or thermal mismatch.

Prevention: thorough cleaning, controlled profile, uniform thickness.

Weak Brazing — due to poor wetting, thin nickel, or oxidation.

Prevention: proper nickel thickness, high vacuum, fresh solder.

Early X-ray/ultrasonic inspection + full process control greatly reduces defects in alumina ceramic metallization brazing.

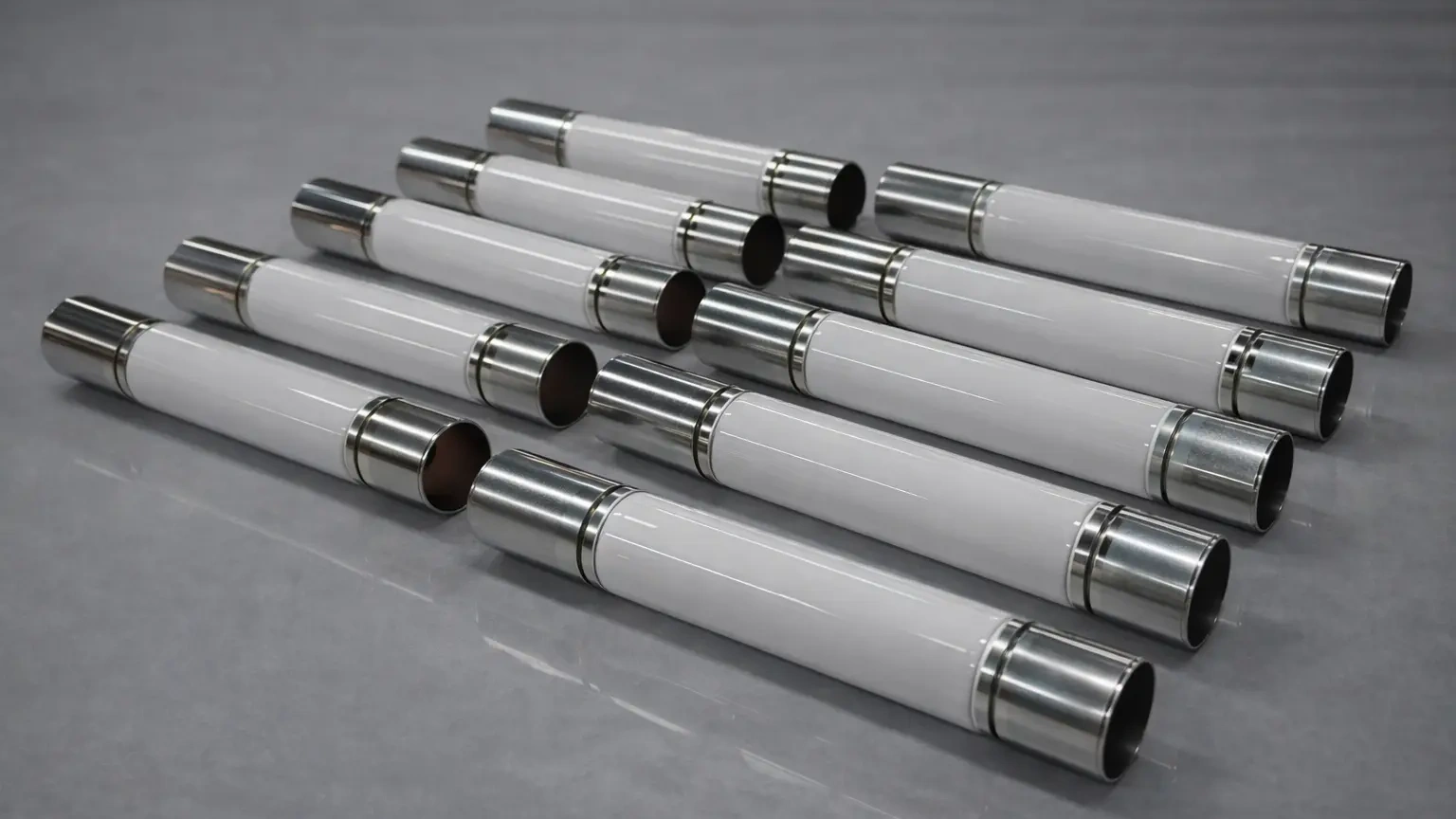

Real-World High-Voltage Feedthrough Examples

In semiconductor vacuum feedthroughs, Mo-Mn + AgCu withstands >50 kV with hermeticity ≤10⁻⁹ Pa·m³/s.

In gas-insulated high-voltage equipment, the process supports reliable long-term operation with very low failure rates.

Optimized layers routinely achieve >20 MPa adhesion.

Conclusion

Mo-Mn metallization remains the go-to solution for alumina ceramic metallization brazing in high-voltage applications.

Mastering slurry application, sintering, nickel plating, brazing parameters, and defect prevention delivers superior reliability and longevity — especially in high-voltage ceramic insulator metallization and high-voltage feedthrough MoMn.

Frequently Asked Questions

-

Which alumina ceramics suit the Mo-Mn process?

→ 96%–99% alumina grades. -

How is metallization adhesion tested?

→ Tensile testing or peel strength measurement. -

Are there AgCu solder alternatives for HV feedthroughs?

→ AgCu is standard; AgCuTi active solder is used in select cases.