Alumina Metallized Ceramics: Bottlenecks & Solutions

Alumina metallized ceramics are widely used in power electronics, automotive electronics, vacuum devices, and LED applications. They are essential for achieving reliable bonding between ceramic and metal. However, several technical bottlenecks during manufacturing still affect product reliability and production yield.

This article systematically reviews the four major bottlenecks, analyzes their root causes, and shares Meetcera’s advanced solutions, real-world application cases, and practical recommendations to help engineers and procurement teams make better decisions.

1. Main Technical Bottlenecks

Due to the chemical inertness of alumina surfaces, the metallization process faces several core challenges:

Poor Adhesion and Reliability Issues

The metal layer tends to delaminate under thermal cycling or mechanical stress, leading to device failure.Process Inconsistency Affecting Performance and Yield

Large variations in metal layer thickness, uniformity, and performance make standardized production difficult.Material and Design Limitations

Limited choice of metals, high process temperatures, and strict atmosphere requirements restrict design flexibility.Hermetic Sealing Challenges

Micro-cracks or pores cause sealing failure, making it hard to meet vacuum or high-pressure requirements.

| Bottleneck | Main Consequences | Impact Level |

|---|---|---|

| Poor Adhesion | Delamination, device failure | Severe |

| Process Inconsistency | Performance variation, low yield | Significant |

| Insufficient Hermeticity | Leakage, vacuum failure | Severe |

2. Root Causes and Mechanisms

These bottlenecks mainly stem from material and process characteristics:

Surface Wettability Problems

Alumina has low surface energy, so molten metal spreads poorly (large contact angle), resulting in weak bonding.Interfacial Chemical Reaction Mechanisms

In traditional processes, the reaction layer is difficult to control, often forming brittle phases or insufficient bond strength.CTE Mismatch and Stress Failure

Alumina’s CTE (≈ 6.5–7.5 × 10⁻⁶ / °C) differs significantly from most metals. Residual stress builds up during cooling, causing cracks or delamination.

For a detailed review on thermal expansion mismatch stresses in ceramic–metal joints, see: Joining of Ceramics and Metals – Annual Reviews (1988)

3. Advanced Solutions

Meetcera overcomes these challenges through the following technical breakthroughs:

Surface Activation Techniques

Plasma treatment or chemical etching increases surface energy and roughness, enabling better mechanical interlocking and chemical bonding.Metallization Process Comparison (Core Recommended Table)

| Process | Temperature (°C) | Atmosphere | Adhesion Strength | Typical Applications |

|---|---|---|---|---|

| Mo–Mn | 1400–1600 | Reducing / Inert | Medium | High-voltage insulation, traditional sealing |

| AMB | 800–1000 | Vacuum / Inert | High | High-reliability power modules |

| DCB | 1060–1080 | Inert / Reducing | High | High-thermal-conductivity power electronics |

- Interface Engineering for Stress Relief

Intermediate layers, gradient interfaces, or compliant layers are used to distribute thermal stress evenly and improve thermal cycling reliability.

For an in-depth discussion on active metal brazing mechanisms and advancements, refer to: A Review of the Alumina / Ag–Cu–Ti Active Metal Brazing Process

Need a tailored process solution?

Contact Meetcera engineers for customized technical support.

4. Real-World Applications

Advanced metallization technologies have significantly improved performance across multiple fields:

Power Electronics

DCB technology enables direct bonding of thick copper layers, delivering excellent thermal conductivity and high current-carrying capacity while extending device lifespan.

View Meetcera power electronics metallized ceramic case studiesAutomotive Electronics

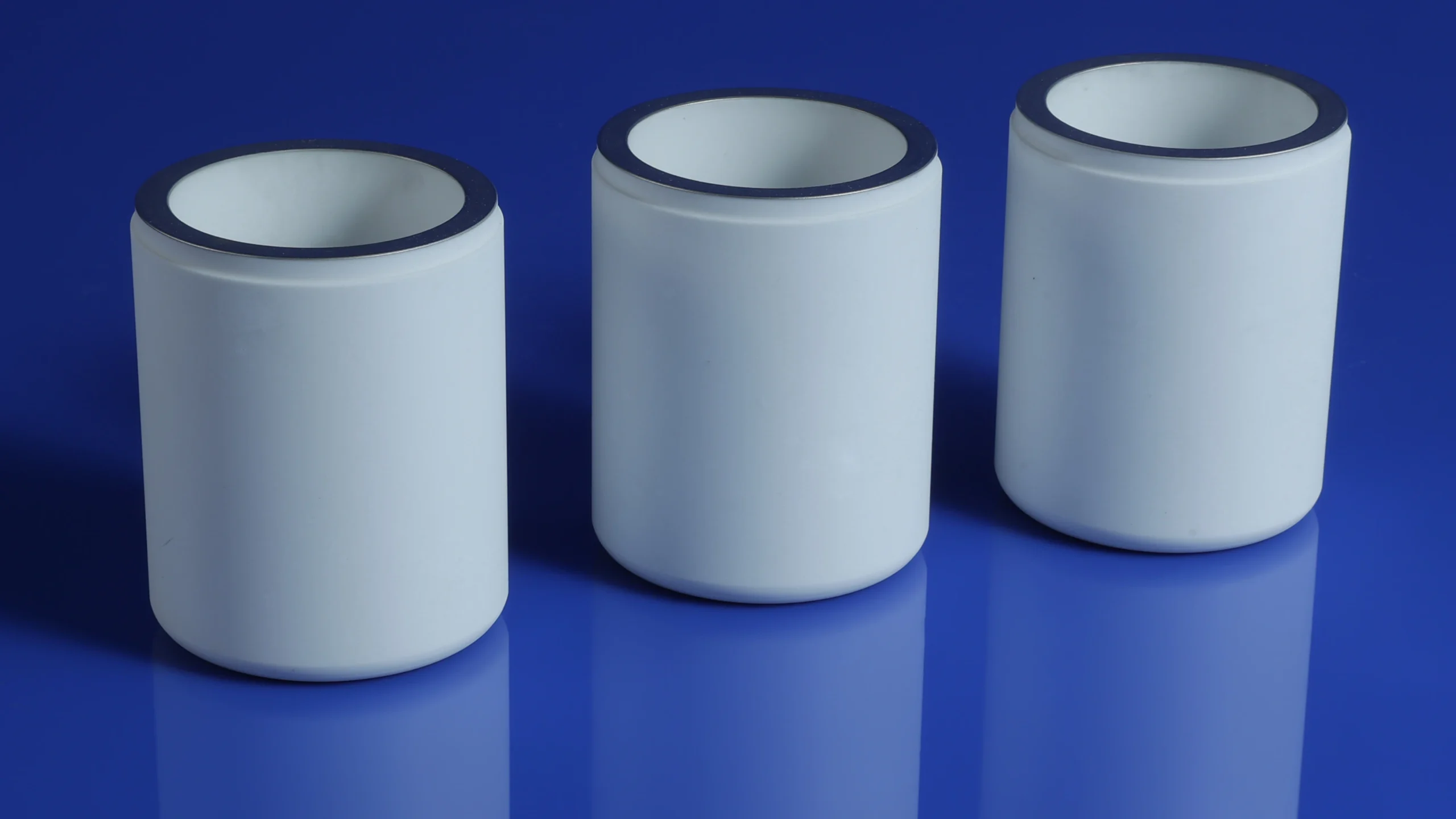

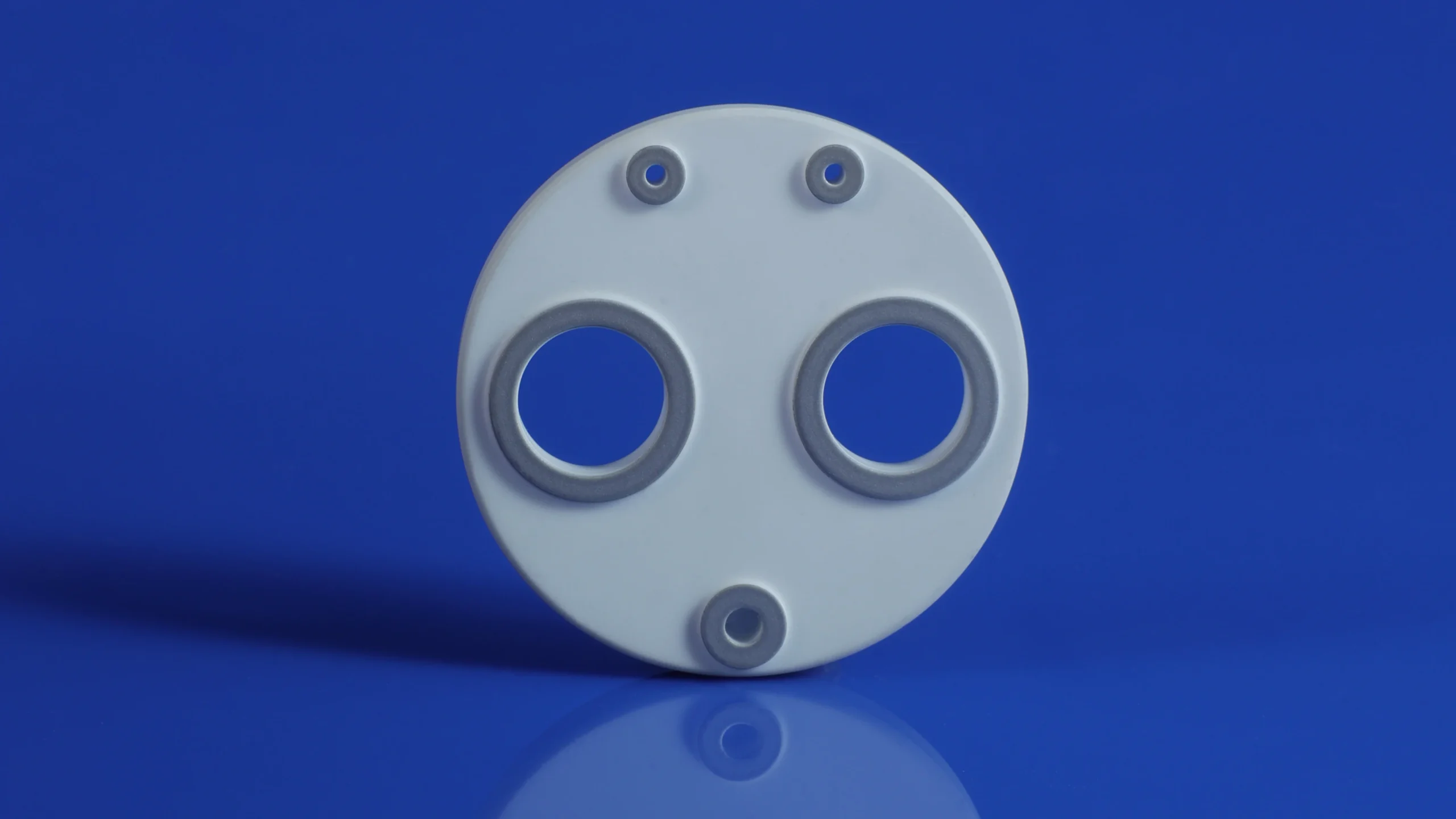

Metallized ceramics withstand high-temperature cycling, vibration, and humidity, ensuring stable operation of ECUs and sensors in harsh environments.Vacuum and RF Devices

High-hermeticity metallization provides reliable vacuum sealing for microwave tubes, X-ray tubes, and feedthrough components.LED and Optoelectronics

High-efficiency heat-dissipating metallized layers reduce junction temperature, improving luminous efficiency and service life.

5. FAQ

Q1: What is the most common failure mode in alumina metallized ceramics?

A: Adhesion delamination and cracks caused by CTE mismatch.

Q2: What is the difference between AMB and DCB processes?

A: AMB uses active metal reaction bonding at lower temperatures, while DCB is specialized for direct copper–ceramic bonding and offers superior thermal performance.

Q3: How can CTE mismatch be solved?

A: It can be effectively relieved through intermediate layers or gradient interface designs.

6. Conclusion

The main technical bottlenecks in alumina metallized ceramics center on adhesion, process consistency, material limitations, and hermetic sealing. Through surface activation, advanced metallization processes (Mo–Mn, AMB, DCB), and interface engineering, these challenges can be effectively addressed.

Optimized solutions significantly enhance product reliability and meet the demands of high-end applications in power electronics, automotive, vacuum, and optoelectronics.

For further academic insights on stress mitigation in ceramic–metal systems, see:

Effect of Interlayers in Ceramic–Metal Joints with Thermal Expansion Mismatches

Need high-reliability alumina metallized ceramic solutions?

Contact the Meetcera technical team today for professional consultation and custom support!