How to Choose the Right Vacuum Feedthrough?

In advanced manufacturing and scientific research, maintaining a pristine vacuum environment is critical. A vacuum feedthrough ensures your system remains sealed while allowing electricity, fluids, or mechanical motion to pass into your vacuum chamber.

Whether you are developing semiconductors, conducting aerospace simulations, or exploring high-energy physics, the right feedthrough can make all the difference.

1. Identify Your Core Requirement

The first step is defining the type of signal or energy you need to transmit. Selecting the correct feedthrough ensures system reliability and vacuum integrity.

| Type | Application / Use Case | Notes |

|---|---|---|

| Electrical & Power | High-voltage or high-current applications | Supports signals from 1 kV up to 100 kV+ |

| Signal Feedthroughs | Sensitive data transmission (thermocouples, coaxial lines) | Maintains signal integrity in UHV environments |

| Vacuum Rotary Feedthroughs | Mechanical motion inside vacuum chamber | Allows rotation or linear movement while preserving vacuum seal |

2. Technical Specifications at a Glance

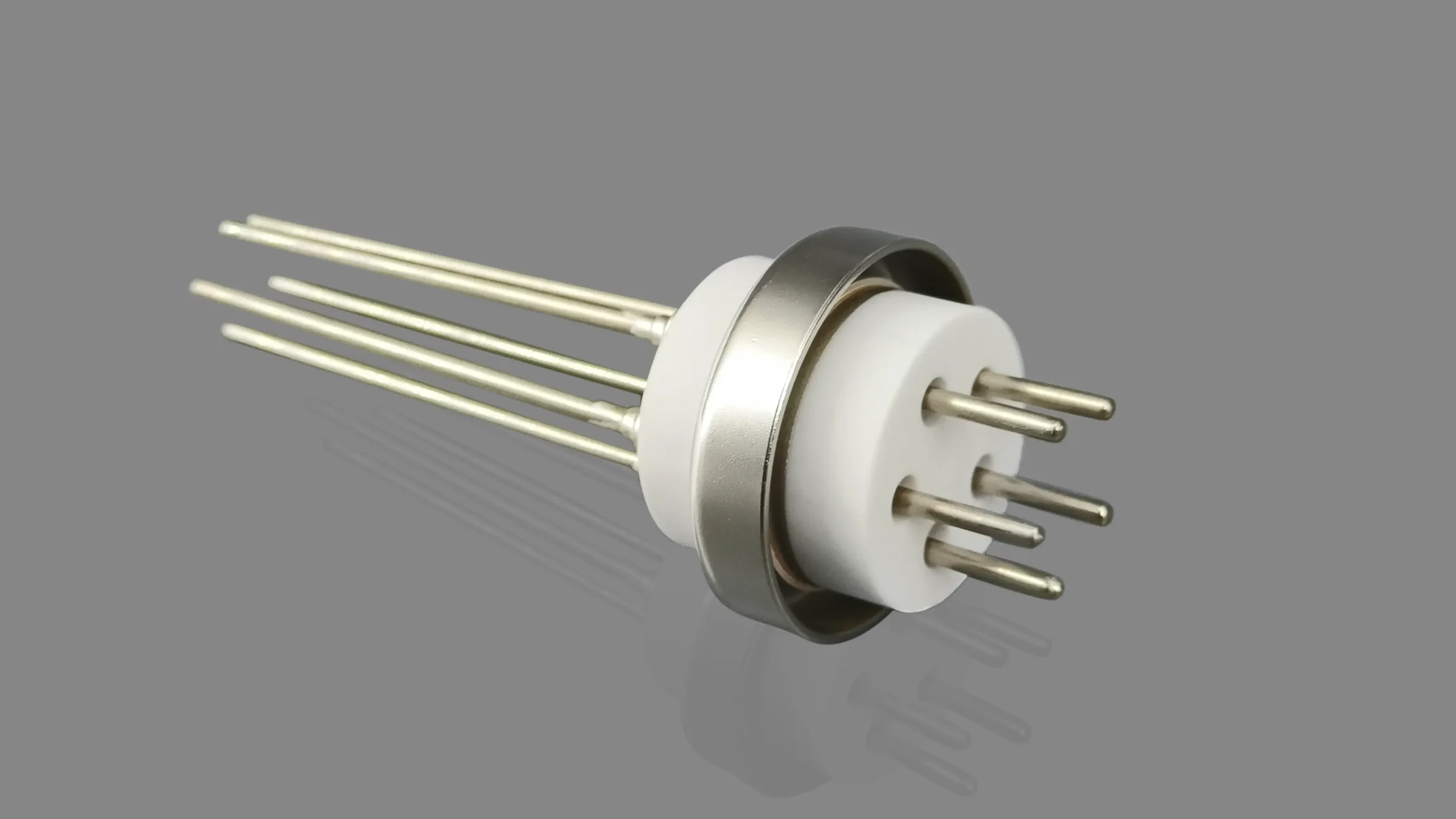

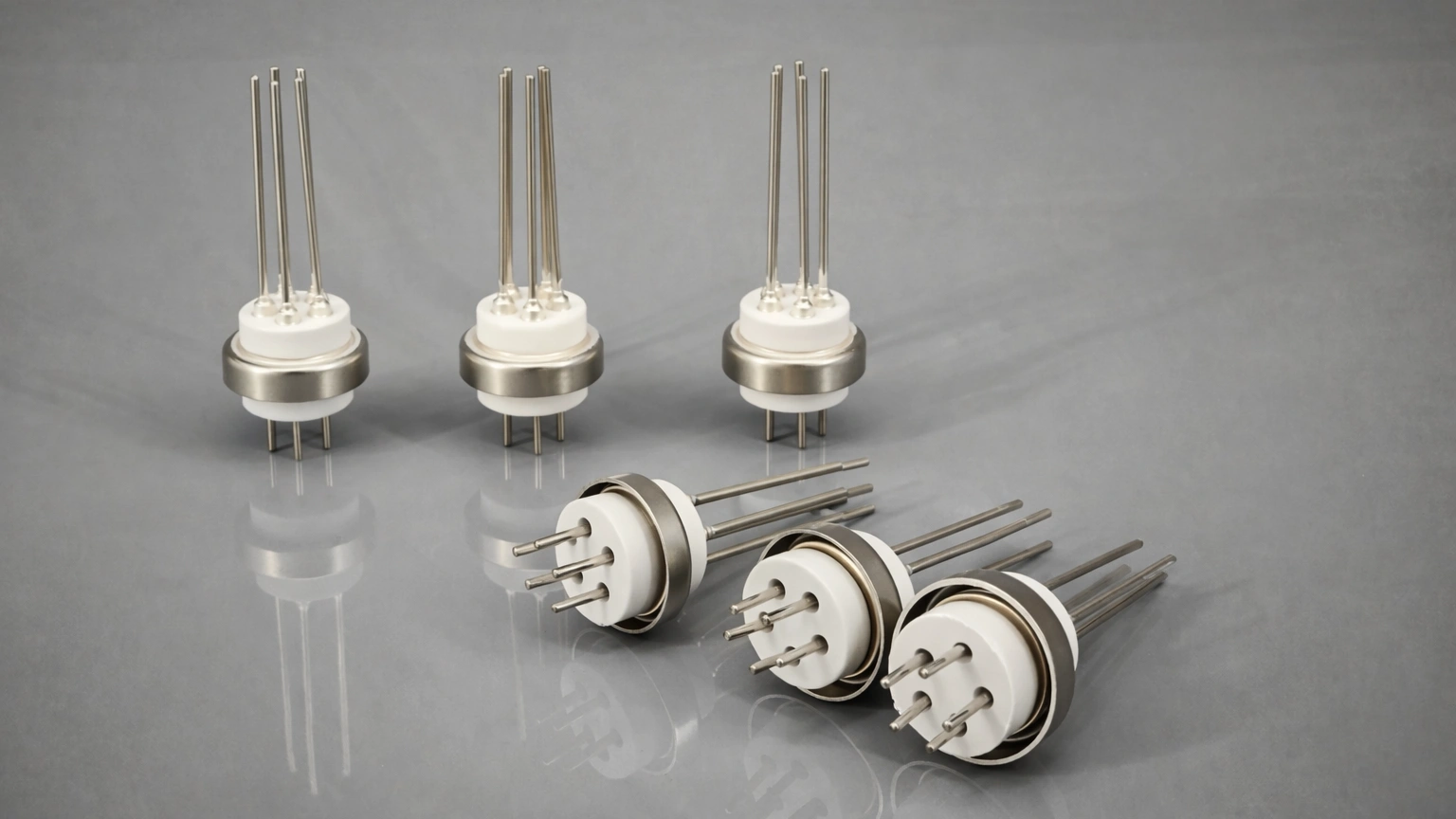

Here’s a summary of Meetcera’s metallized ceramic feedthroughs, suitable for ultra-high vacuum (UHV) and extreme conditions:

| Feature | Specification Details | Benefit |

|---|---|---|

| Insulation Material | 95% – 99.7% Alumina (Al₂O₃) | High dielectric strength & thermal resistance |

| Seal Type | Hermetic Ceramic-to-Metal Brazing | Long-term vacuum integrity |

| Leak Rate | < 1 × 10⁻¹⁰ atm·cc/sec (He) | Perfect for UHV applications |

| Voltage Range | 1 kV – 100 kV+ | Supports both signal & high-power applications |

| Temperature Range | −269 °C to 450 °C | Cryogenic & high-temperature bakeout compatibility |

3. Advantages of Metallized Ceramic Technology

Metallized ceramics outperform traditional glass-to-metal seals in thermal, electrical, and mechanical durability.

Key Benefits

High Thermal Stability

Resists extreme temperature cycles during UHV bakeouts.Superior Dielectric Strength

Provides reliable insulation for high-voltage applications.Mechanical Robustness

Durable under industrial handling and long-term operation.

According to Stanford Materials Science, alumina ceramics maintain structural integrity under extreme vacuum stress, making them ideal for mission-critical applications.

4. Frequently Asked Questions (FAQ)

Q: Can these feedthroughs operate in cryogenic environments?

A: Yes. Ceramic-to-metal seals remain hermetically tight at temperatures as low as −269 °C (liquid helium).

Q: What is the maximum bakeout temperature for UHV feedthroughs?

A: Most CF-flanged feedthroughs can withstand 450 °C, ensuring ultra-high vacuum readiness (NASA Vacuum Outgassing Data).

Q: How do you ensure leak-tight performance?

A: Every unit is tested via Helium Mass Spectrometer Leak Detection, achieving leak rates below 1 × 10⁻¹⁰ atm·cc/sec.

Q: Which feedthrough is best for high-voltage cryogenic applications?

A: Metallized ceramic high-voltage feedthroughs are ideal due to their thermal shock resistance and superior insulation.

5. Ready to Optimize Your Vacuum System?

Choosing the right vacuum feedthrough is a balance of electrical specifications, thermal performance, and material science. At Meetcera, we deliver precision-engineered solutions for critical vacuum applications.

Explore Your Options

Browse Our Catalog

Find the full range of metallized ceramic and UHV feedthroughs.Get a Custom Quote

Submit your technical drawings for a free engineering review.Consult an Expert

Discuss your specific voltage, pressure, and temperature requirements.

Don’t compromise on vacuum integrity. Choose Meetcera for world-class hermetic sealing solutions.