Vacuum and Hermetic Feedthroughs: Types, Materials & Applications

Vacuum and hermetic feedthroughs play a critical role in modern vacuum systems, enabling the safe and reliable transmission of electrical signals, fluids, motion, or thermal energy through a sealed vacuum boundary. They are widely used in industries such as semiconductor manufacturing, aerospace, medical devices, and scientific research, where maintaining vacuum integrity and leak-tight performance is essential.

This article provides a comprehensive introduction to vacuum and hermetic feedthroughs, including their definitions, differences, types, materials, applications, and key considerations for selecting the right feedthrough for your system.

1.What Is a Vacuum Feedthrough?

A vacuum feedthrough is a component designed to allow electrical, mechanical, or fluid connections to pass through the wall of a vacuum chamber while maintaining the required vacuum level inside the system.

Vacuum feedthroughs are commonly used in:

- Vacuum chambers

- Deposition systems

- Analytical instruments

- Research and laboratory equipment

Depending on the application, vacuum feedthroughs may use elastomer seals, metal gaskets, or other sealing methods to achieve acceptable leak rates for low to high vacuum environments.

2.What Is a Hermetic Feedthrough?

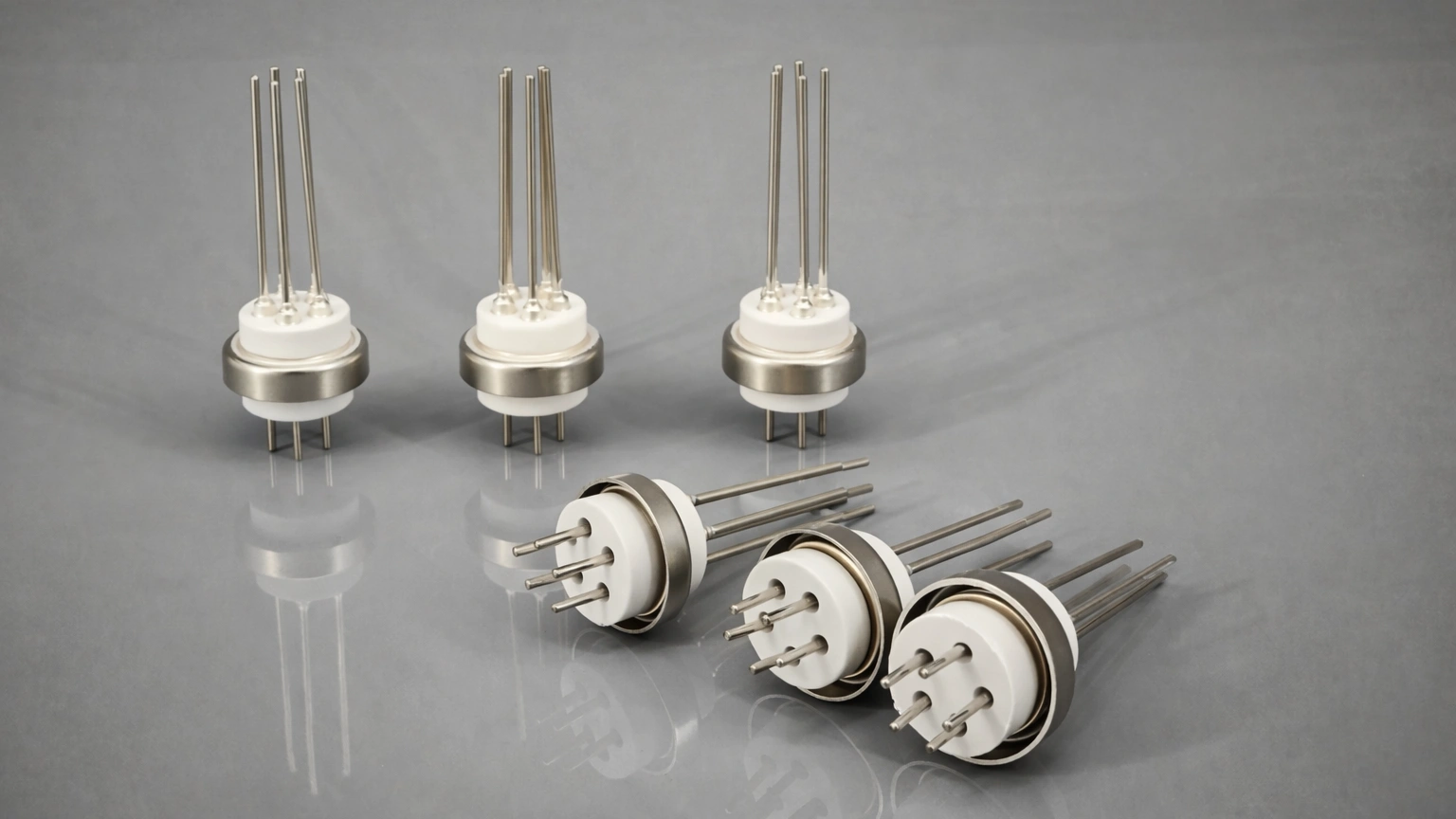

A hermetic feedthrough is a specialized type of feedthrough that provides a gas-tight (hermetic) seal, preventing any leakage between internal and external environments. Hermetic feedthroughs are typically manufactured using ceramic-to-metal or glass-to-metal sealing technologies, resulting in extremely low leak rates.

Hermetic feedthroughs are designed to meet strict leak rate requirements defined by international standards organizations such as the International Organization for Standardization (ISO), making them ideal for critical and long-life applications.

Hermetic feedthroughs are essential in applications that require:

- Ultra-high vacuum (UHV)

- Long-term reliability

- High pressure or harsh environments

- Strict leak rate standards

3.Vacuum Feedthrough vs Hermetic Feedthrough

Although the terms are sometimes used interchangeably, there are important differences between vacuum and hermetic feedthroughs.

| Feature | Vacuum Feedthrough | Hermetic Feedthrough |

|---|---|---|

| Sealing method | Elastomer or mechanical seals | Ceramic-to-metal or glass-to-metal |

| Typical leak rate | Moderate | Extremely low (hermetic) |

| Vacuum level | Low to high vacuum | High vacuum to ultra-high vacuum |

| Reliability | Application-dependent | Long-term, high reliability |

| Common use | General vacuum systems | Aerospace, medical, semiconductor |

Understanding the difference between vacuum feedthrough vs hermetic feedthrough is essential when selecting components for critical vacuum applications.

4.Types of Vacuum and Hermetic Feedthroughs

Vacuum and hermetic feedthroughs can be broadly classified into three main types based on their function and application requirements. Each type is designed to transmit specific forms of energy or motion through a vacuum boundary while maintaining vacuum integrity.

| Feedthrough Type | Product Description | Typical Applications |

|---|---|---|

| Electrical Vacuum Feedthroughs | Designed to transmit electrical power or signals through a vacuum boundary while maintaining reliable sealing. Available in low-voltage, high-voltage, multi-pin, coaxial, and triaxial configurations. | Semiconductor manufacturing equipment, vacuum coating systems, particle accelerators, electron microscopes, medical imaging devices |

| Thermal Vacuum Feedthroughs | Used to transfer heat into or out of a vacuum chamber for heating or temperature control purposes. These feedthroughs must withstand high temperatures, thermal cycling, and vacuum conditions. | Vacuum furnaces, heating chambers, material testing equipment, vacuum heat treatment systems, high- or low-temperature experimental setups |

| Fluid & Mechanical Vacuum Feedthroughs | Enable the controlled transfer of gases, liquids, or mechanical motion (rotary or linear) into a vacuum system while maintaining a leak-tight seal. | Gas delivery systems, chemical vapor deposition (CVD), vacuum reactors, valve control systems, motion and positioning platforms |

For applications requiring reliable signal transmission and insulation performance, our range of electrical vacuum feedthroughs offers customizable configurations for demanding vacuum environments.

5. Materials Used in Hermetic Feedthroughs

Material selection has a significant impact on performance, durability, and compatibility.

Common materials include:

Ceramics (Alumina)

Excellent electrical insulation, high temperature resistance, and low outgassing.

Advanced ceramic hermetic feedthroughs are widely used in high-voltage and high-temperature applications due to their excellent insulation and sealing stability.Metals (Kovar, Stainless Steel)

Provide mechanical strength and thermal compatibility with ceramic sealing.Glass-to-Metal Seals

Used for specific electrical and sensor feedthrough applications requiring precision sealing.

The combination of these materials enables hermetic feedthroughs to achieve extremely low leak rates and long service life.

6.Key Applications of Vacuum and Hermetic Feedthroughs

Vacuum and hermetic feedthroughs are widely used across high-tech industries, including:

- Semiconductor Manufacturing – wafer processing, deposition, and etching systems

- Aerospace and Defense – avionics, satellites, and high-reliability electronics, where vacuum integrity and hermetic sealing are critical for mission success (NASA)

- Medical Devices – implantable devices and diagnostic equipment

- Scientific Research – particle accelerators, electron microscopes, and vacuum experiments conducted at large-scale facilities such as those operated by CERN

Each application has unique requirements for vacuum level, electrical performance, and environmental resistance.

7.How to Choose the Right Vacuum or Hermetic Feedthrough

Selecting the right feedthrough is critical to system performance and reliability. Key factors to consider include:

- Required vacuum level (low, high, or ultra-high vacuum)

- Acceptable leak rate

- Operating temperature range

- Electrical or mechanical requirements

- Material compatibility with the environment

- Long-term reliability and maintenance needs

For high-reliability systems and ultra-high vacuum conditions, selecting certified hermetic feedthrough solutions can significantly improve long-term system performance.

Conclusion

Vacuum and hermetic feedthroughs are essential components for maintaining vacuum integrity while enabling critical connections across sealed boundaries. By understanding the differences, types, materials, and applications, engineers can select the most suitable feedthrough for their systems and ensure reliable, long-term performance.

For high-reliability and high-vacuum applications, hermetic feedthroughs remain the industry standard.