Metallized Ceramics in High-Frequency RF Components ?

When I talk with engineers designing 5G base stations, they often share their biggest headaches. Building equipment that works at very high radio frequencies (RF) and handles lots of data is not easy. There are many hidden challenges. One technology that helps solve some of these challenges is the use of metallized ceramics1 in RF components. This article will look at the problems engineers face and how this material provides answers.

What Challenges Does 5G Bring?

Building 5G networks means working at higher frequencies than older mobile systems. This lets us send much more data, much faster. But higher frequencies bring new problems. Signals are harder to control. Components get hotter. Everything needs to be smaller because base stations use technology like Massive MIMO, which packs many antennas and circuits together. Materials used inside these stations must handle these tough conditions perfectly. Failure of one small part can affect many users.

How do we keep the high-frequency signal clean?

When radio signals travel through materials, they can lose energy or get distorted. This is called dielectric loss. At the high frequencies used in 5G, this loss becomes a much bigger problem. If the material around the signal path absorbs too much energy or changes the signal's timing, the data gets corrupted. The base station cannot send or receive information correctly. This limits the range and speed of the network. Engineers need materials with very low loss at these frequencies.

We need a material that allows radio waves to pass through or travel along its surface with minimal energy loss and without distorting the signal shape or timing, especially at gigahertz frequencies.

Metallized ceramics, particularly those made from high-purity alumina, have very low dielectric loss2 at high frequencies. This means they absorb very little energy from the RF signal. They also have stable electrical properties as temperature changes. This helps keep the signal clean and strong as it moves through the component. Using these ceramics helps engineers maintain signal integrity, which is vital for high-speed data transmission in 5G.

How do we handle the heat inside the box?

5G base stations, especially the parts that send and receive signals (the radios), generate a lot of heat. Packing many powerful electronic components into a small space makes heat management a major challenge. If the heat is not moved away effectively, the electronic chips overheat. This reduces their performance. It shortens their lifespan. In extreme cases, it can cause them to fail completely. Reliable operation needs materials that can help spread or move this heat away from sensitive areas.

We require a material that can act as an electrical insulator to separate components but also conducts heat well away from the heat-generating sources like power amplifiers.

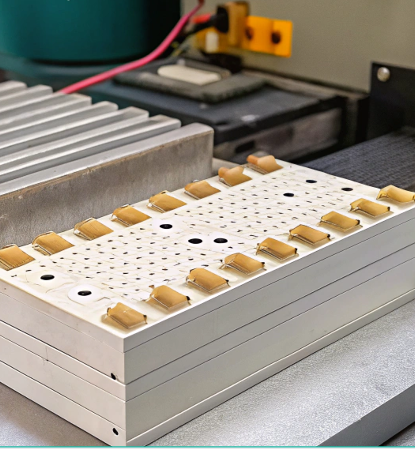

Ceramics like alumina are excellent electrical insulators. But importantly, they also have good thermal conductivity3 compared to many other insulators like plastics. Metallized ceramic substrates or packages can act as a base for RF components. They provide electrical isolation while helping to draw heat away from the chips and spread it out. This keeps the electronic components cooler, which improves their performance and makes them last longer. It is a critical feature for densely packed 5G radios.

How do we make strong, reliable electrical links?

Connecting sensitive RF chips and circuits to the rest of the system is hard, especially when dealing with high frequencies and heat cycles. Traditional methods might not provide a stable enough connection for fast signals. Also, electrical connections need to be strong mechanically and handle potential temperature changes without failing. A poor connection causes signal loss or intermittent operation. Reliability over many years in the field is key for base stations.

We need a way to create precise, low-resistance electrical connections between ceramic parts and metal contacts or leads, connections that will not fail under thermal stress or vibration.

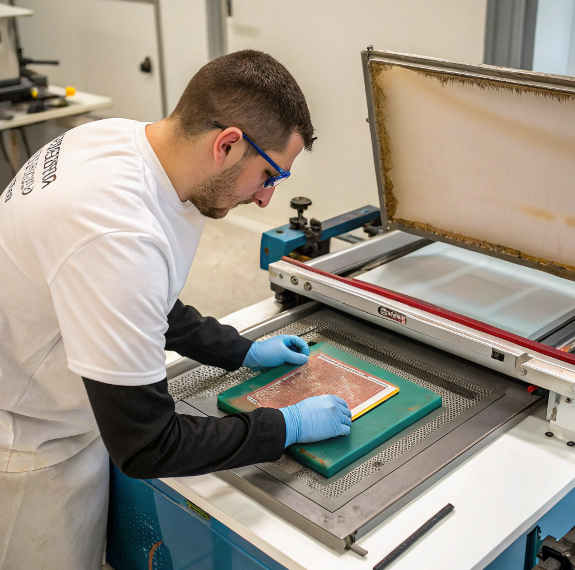

This is where the "metallized" part of metallized ceramics is essential. A thin layer of metal is put onto the ceramic surface in a specific pattern. This metal layer can then be easily soldered or brazed to pins, leads, or other metal structures. This process creates very strong and reliable electrical and mechanical connections. These joints can handle temperature changes and vibrations better than many other joining methods. I saw a client improve the yield of their RF modules significantly by switching to metallized ceramic substrates for more reliable connections.

How do we protect the sensitive parts from outside?

5G base stations are often placed outdoors on towers or rooftops. They must survive harsh weather. This includes rain, humidity, wide temperature swings, and even salt spray near the coast. The sensitive electronic components inside must be protected from moisture, dust, and chemicals. The packaging needs to be sealed tight, or "hermetic." Maintaining this seal over many years in tough conditions is a major engineering hurdle.

We need packaging materials and joining methods that can create a perfect, long-lasting seal around the electronic components to keep out the environment.

Through the metallization process, ceramic components can be brazed to metal housings or lids. Brazing creates a molecular bond between the metal layer on the ceramic and the metal package. This bond is very strong and, importantly, it is hermetic. This means it forms a perfect seal that gases and liquids cannot pass through. Using metallized ceramic packages or feedthroughs is a standard way to protect sensitive RF circuits inside 5G base stations from harsh outdoor conditions, ensuring long-term reliability.

How do we make everything smaller?

Modern 5G base stations, especially those using advanced antenna technology like Massive MIMO, need to be very compact. This means all the components inside must be as small as possible and perform multiple functions if possible. Traditional packaging methods might take up too much space or cannot integrate different functions like signal routing, heat management, and environmental protection into one piece. Miniaturization is key to fitting more technology into less space.

We need materials and manufacturing methods that allow for complex, small shapes and potentially integrate electrical paths within the insulating material itself.

Ceramic processing allows for creating complex 3D shapes and fine features. With advanced ceramic techniques like multi-layer ceramic technology, electrical pathways (made of metal) can be built inside the ceramic body itself. Metallization can be applied to specific areas for external connections. This integration capability means that a single metallized ceramic component can act as a structural part, an insulator, a heat spreader, and a base for complex circuitry, all while being very compact. This helps engineers miniaturize the RF components needed for crowded 5G base station designs.

| Feature | Standard RF Substrate (e.g., PCB) | Metallized Ceramic Substrate | Benefit for 5G RF Components |

|---|---|---|---|

| Dielectric Loss @ High Freq | Higher | Very Low | Better signal integrity, less energy loss |

| Thermal Conductivity | Lower | Good | More effective heat management, cooler chips |

| Hermetic Sealing | Difficult/Impossible | Achievable via brazing | Environmental protection for sensitive parts |

| High Temp Performance | Limited | Excellent | Reliable operation in hot environments |

| Mechanical Strength | Varies, often lower | High stiffness and strength | More robust packaging |

| Feature Size / Integration | Limits on trace width/layers | Very fine features, multi-layer capability | Allows for miniaturization and complexity |

This table summarizes the technical advantages that metallized ceramics offer compared to some common alternatives in RF applications. These technical points translate directly into performance and reliability benefits for the final 5G product.

Metallized Ceramics Step In

Putting all these answers together, we see that metallized ceramics are a powerful solution for the tough demands of 5G RF components. They provide the low signal loss needed for high frequencies, handle the heat generated by powerful chips, allow for reliable electrical connections and hermetic sealing for environmental protection, and support the miniaturization needed for compact base station designs. It is not just one property; it is the combination of electrical, thermal, mechanical, and joining capabilities that makes them ideal.

How Metallized Ceramics Boost 5G RF Performance

Working in the field of advanced materials, I see how new technologies push the limits of what materials can do. 5G wireless technology is a great example. It needs components that perform perfectly at very high frequencies. It also needs them to be small and handle heat. This creates significant challenges. My experience shows me that traditional materials often struggle here. This is why metallized ceramics are becoming very important for 5G radio frequency (RF) systems.

Why is effective heat removal so important for 5G RF components, and what happens if you cannot do it well?

We will look at where the heat comes from and its bad effects. Then we see what the challenge is in 5G designs.

High-frequency operation and increased power density in small 5G components create significant heat. If this heat is not moved away quickly, the component temperature rises. This reduces performance, makes the part less efficient, shortens its life, and can cause it to fail early. Compact 5G designs have less space for traditional cooling.

What causes signal degradation at the high frequencies used in 5G, and why is it a major concern?

We will discuss how signals interact with materials at high speed. Then we see the impact of losing signal strength.

At 5G frequencies (like sub-6 GHz and mmWave), RF signals are sensitive to the properties of the materials they travel through or over. Materials with high dielectric loss absorb signal energy, causing signal degradation and power loss. This weakens the signal before it reaches the antenna or device, reducing range and data speed.

Why is making 5G RF modules smaller so difficult, and what limits the level of integration you can achieve

We will talk about the need for small size in 5G devices. Then we see how combining different parts is hard with many materials.

5G devices need to be compact for user equipment and dense network deployments. Integrating multiple RF functions (like power amplifiers, filters, and antenna interfaces) into a small module is challenging because different components need different materials and joining methods. This makes it hard to build complex 3D structures or combine passive and active elements efficiently.

What makes packaging for 5G RF components so critical for long-term performance, and what happens if the package is not robust?

We will discuss the package's job in protecting the sensitive RF circuit. Then we see the problems that come from a weak package.

The package protects the sensitive RF circuitry from the environment and provides electrical and thermal connections. If the package is not strong, sealed correctly (hermetic), or cannot handle temperature changes, moisture or contaminants can enter. This damages the circuit inside, leading to degraded performance or failure. Mechanical stress from temperature changes can also break connections.

What environmental factors pose risks to 5G RF equipment, and why is material resistance important?

We will list some common environmental challenges. Then we discuss how materials must withstand them.

5G infrastructure and some user devices operate in varied environments, facing temperature extremes, humidity, and sometimes corrosive elements or physical shock. Materials that cannot withstand these conditions degrade over time. This leads to performance drops or outright failure of the RF components and the system they are part of.

Performance Benefits in 5G Systems

Using metallized ceramics in 5G RF components leads to clear performance boosts. You get better signal quality because of lower losses. This means longer range and faster data speeds. You get higher power handling capability because heat is managed more effectively. Components last longer, reducing maintenance costs. The ability to create smaller, integrated modules helps build more compact and efficient devices and base stations. Reliability in tough environments means less downtime and lower operating expenses over the life of the equipment.

| Feature | Standard Packaging Material (e.g., Plastic) | Metallized Ceramic Package | Benefit to 5G RF Performance |

|---|---|---|---|

| Dielectric Loss @ 5G | Higher | Lower | Reduced signal attenuation, better range/speed |

| Thermal Conductivity | Lower | High (especially AlN) | More effective heat dissipation, higher power OK |

| Hermetic Sealing | Difficult/Impossible | Achievable via brazing | Protects components from moisture and contaminants |

| High-Temp Stability | Lower | Very High | Reliable operation in hot conditions |

| CTE Matching | Can be poor with chips | Can be tailored | Reduced stress on components, improved reliability |

| Integration Capability | Limited 3D complexity | Enables Multi-Layer designs | Supports miniaturization and complex circuitry |

| Environmental Robustness | Lower | High | Reliable performance in harsh outdoor/industrial settings |

Real-World Impact and Benefits

Using metallized ceramic components in 5G RF systems makes a big difference.

First, signal performance improves significantly. Lower signal loss means base stations can cover a wider area or transmit data faster. This is critical for meeting 5G performance goals.

Second, heat management is better. Components run cooler. This reduces the risk of failure due to overheating. Equipment lasts longer, which means fewer replacements are needed.

Third, the ability to create strong, hermetic, ceramic-to-metal seals is vital. It protects sensitive electronics from the environment. This is especially important for base stations placed outside in varying weather conditions. A reliable seal prevents moisture ingress, which can cause corrosion and failure.

Fourth, the mechanical strength of ceramic provides robustness against vibration and handling during installation.

Here is a quick look at the comparison:

| Feature | Traditional RF Material (e.g., some plastics) | Metallized Ceramic (Alumina) | Benefit to Customer |

|---|---|---|---|

| High-Frequency Signal Loss | High | Low | Improved range and data speed |

| Thermal Conductivity | Low | High | Better heat management, higher power |

| Temperature Stability (RF) | Properties change with temp. | Stable properties | Consistent signal performance |

| Hermetic Sealing to Metal | Difficult, often non-hermetic | Easy via brazing, hermetic | Environmental protection, reliability |

| Environmental Resistance | Can degrade (UV, moisture) | Highly resistant | Longer lifespan outdoors |

| Mechanical Strength | Lower | High | More robust equipment |

This table shows the clear advantages. These are not small differences; they directly impact network performance and cost of ownership.

Conclusion

Building 5G base stations presents significant engineering challenges, especially when dealing with high-frequency RF signals, heat, reliability, and miniaturization. Traditional materials often cannot meet these demanding requirements simultaneously. Metallized ceramics provide a powerful solution by offering low dielectric loss, good thermal conductivity, strong and hermetic joining capabilities, and suitability for complex, compact designs. By addressing the core technical pain points faced by RF engineers, metallized ceramics play a quiet but critical role in enabling the performance and reliability of 5G networks. Their unique combination of properties makes them essential components in the high-frequency world of 5G.

-

Explore how metallized ceramics enhance performance in 5G applications, ensuring reliability and efficiency in high-frequency environments. ↩

-

Understanding dielectric loss is crucial for maintaining signal integrity in 5G networks. This resource will deepen your knowledge on the topic. ↩

-

Learn about the significance of thermal conductivity in 5G technology and how it impacts the performance and longevity of base stations. ↩

No comment