-

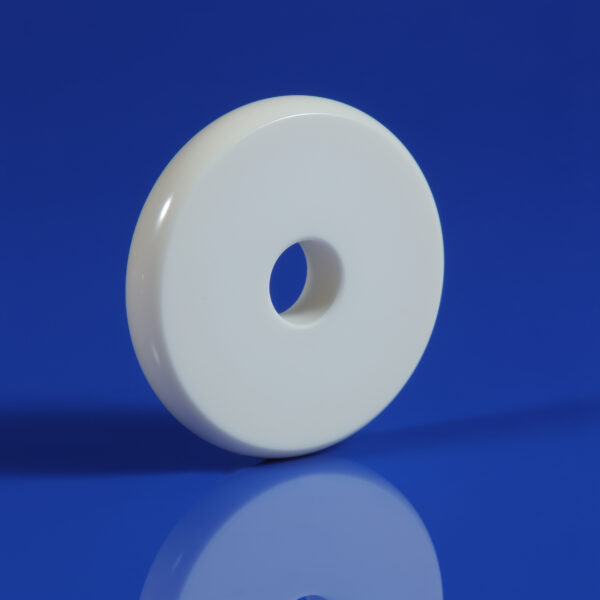

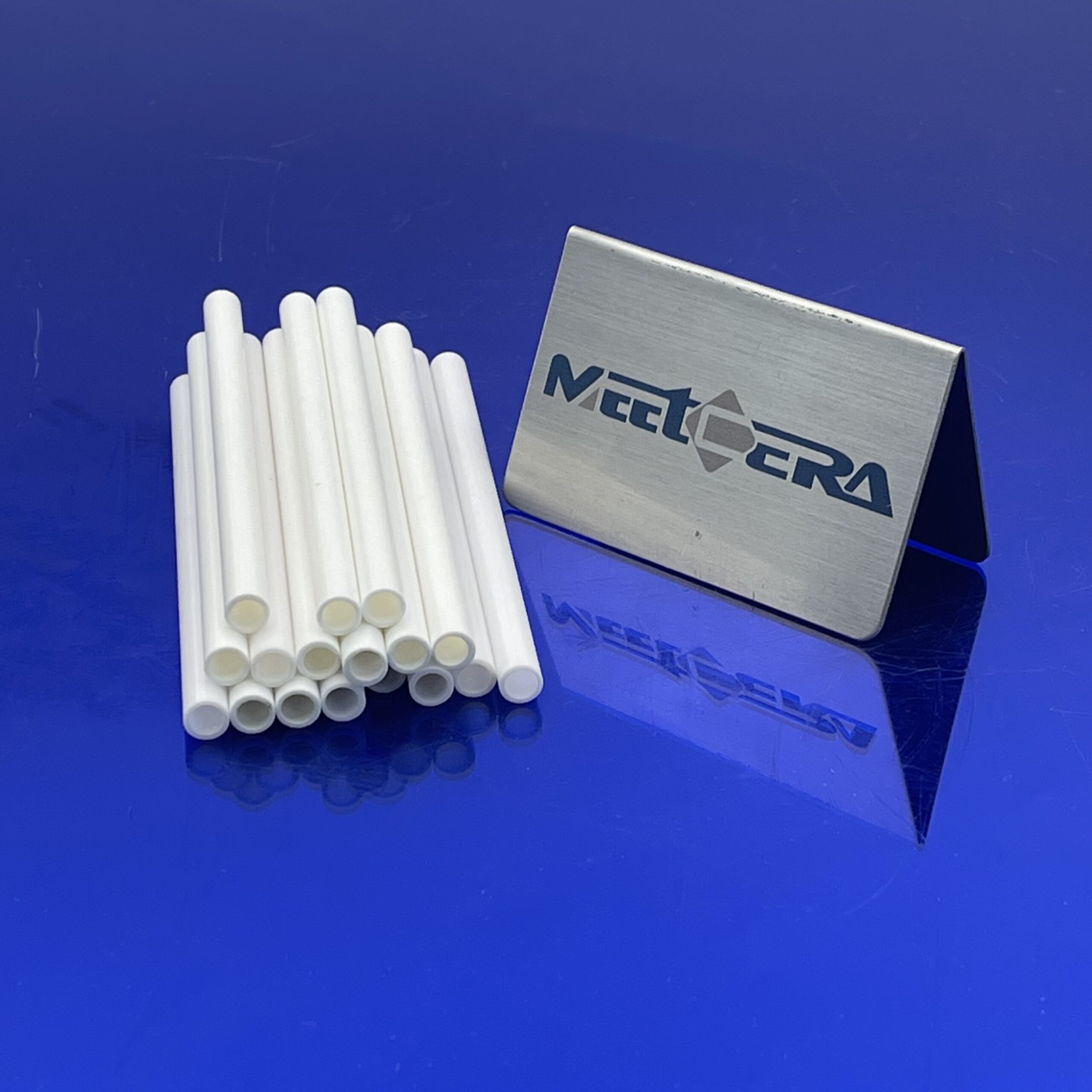

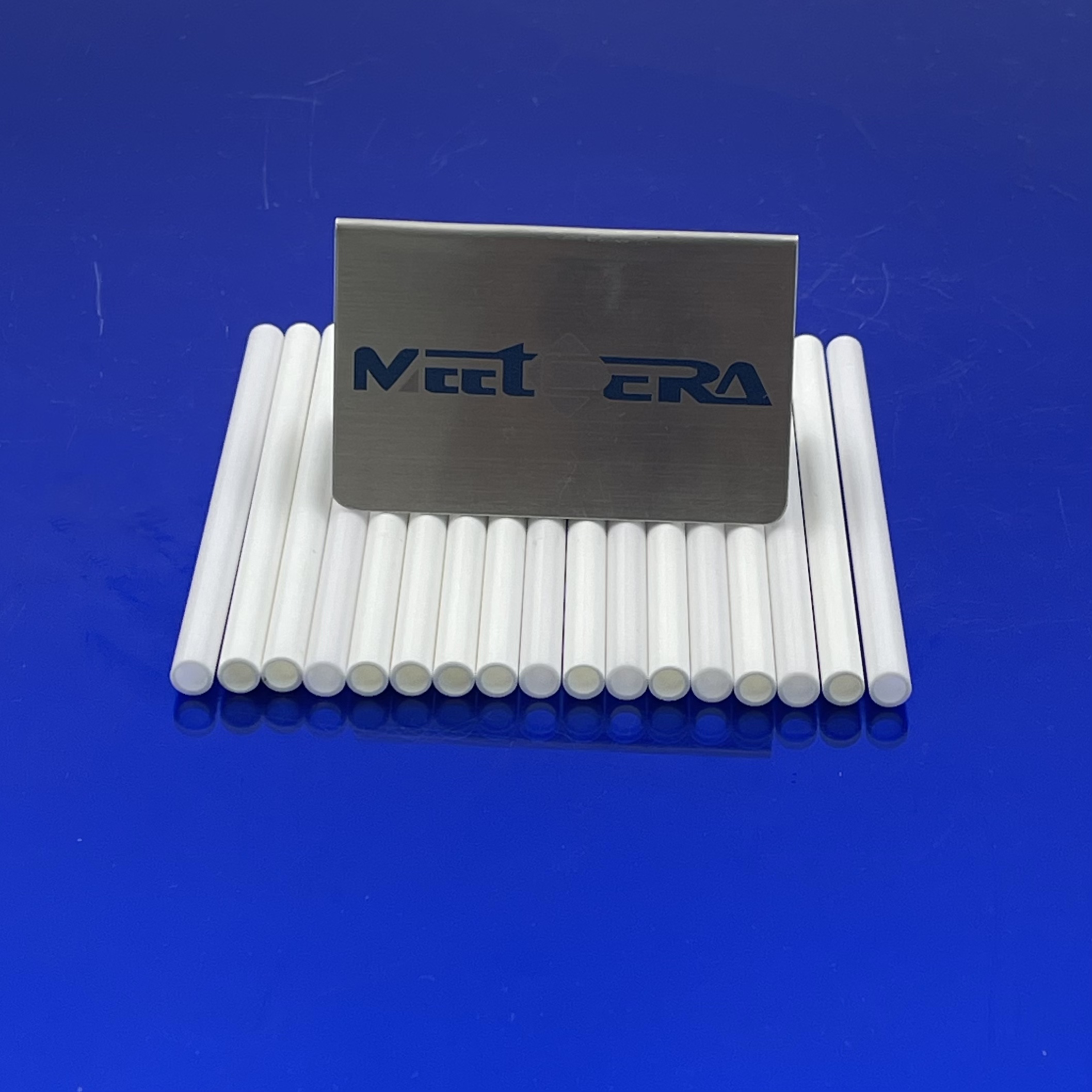

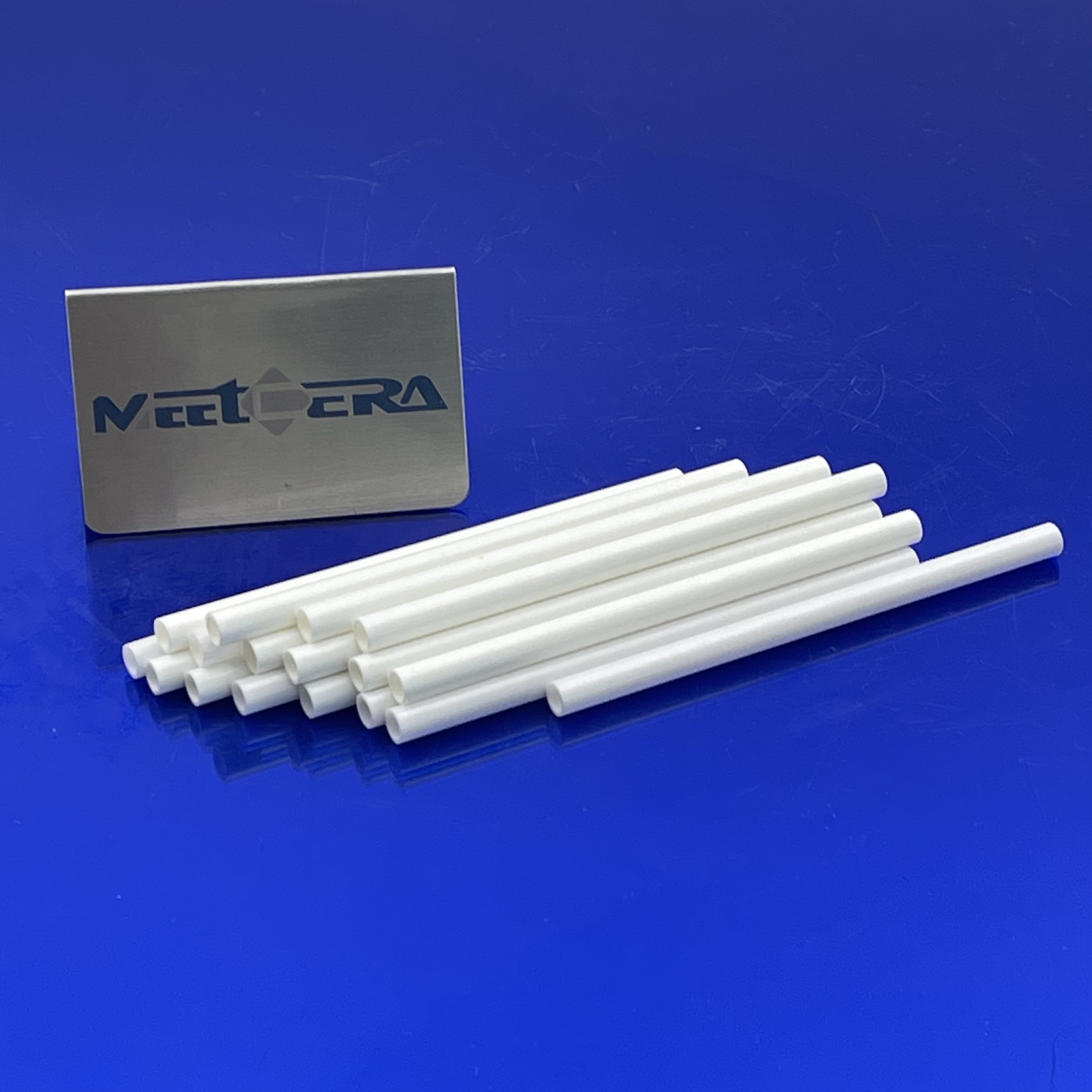

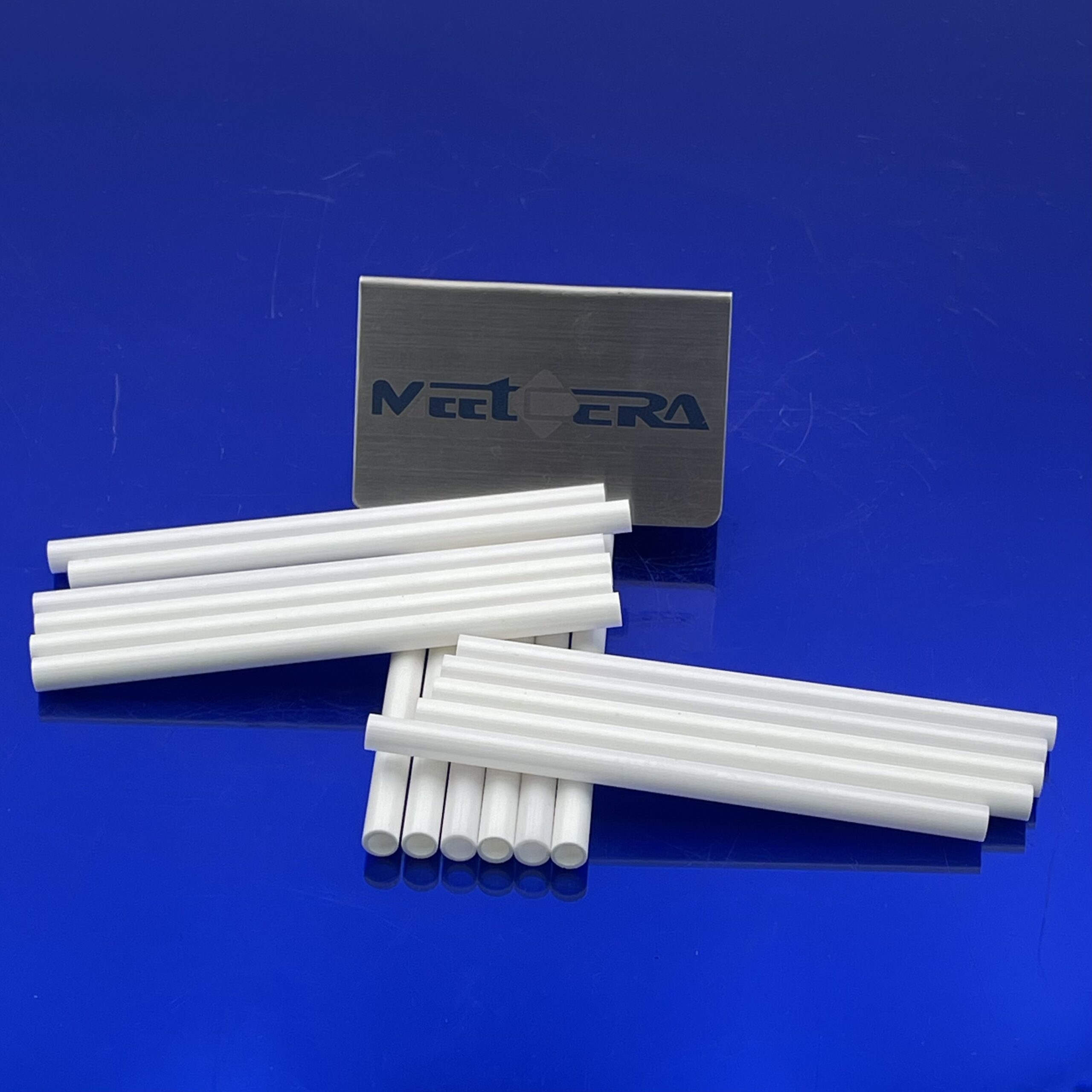

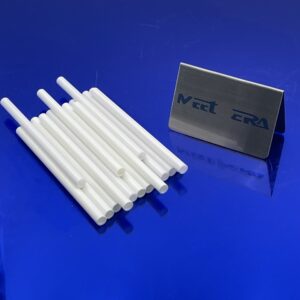

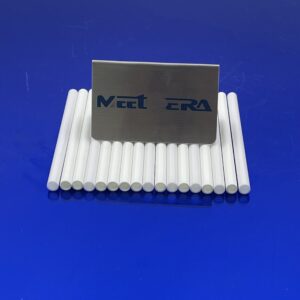

Alumina ceramic through-tubes for Appearance and color:

It presents a pure white color. The appearance is pure and elegant, giving people a visual feeling of cleanliness and hygiene. This white appearance is particularly suitable in application scenarios with high cleanliness requirements, such as in biomedical and food filtration fields. It is also convenient to observe whether there are stains or impurities attached to its surface.

-

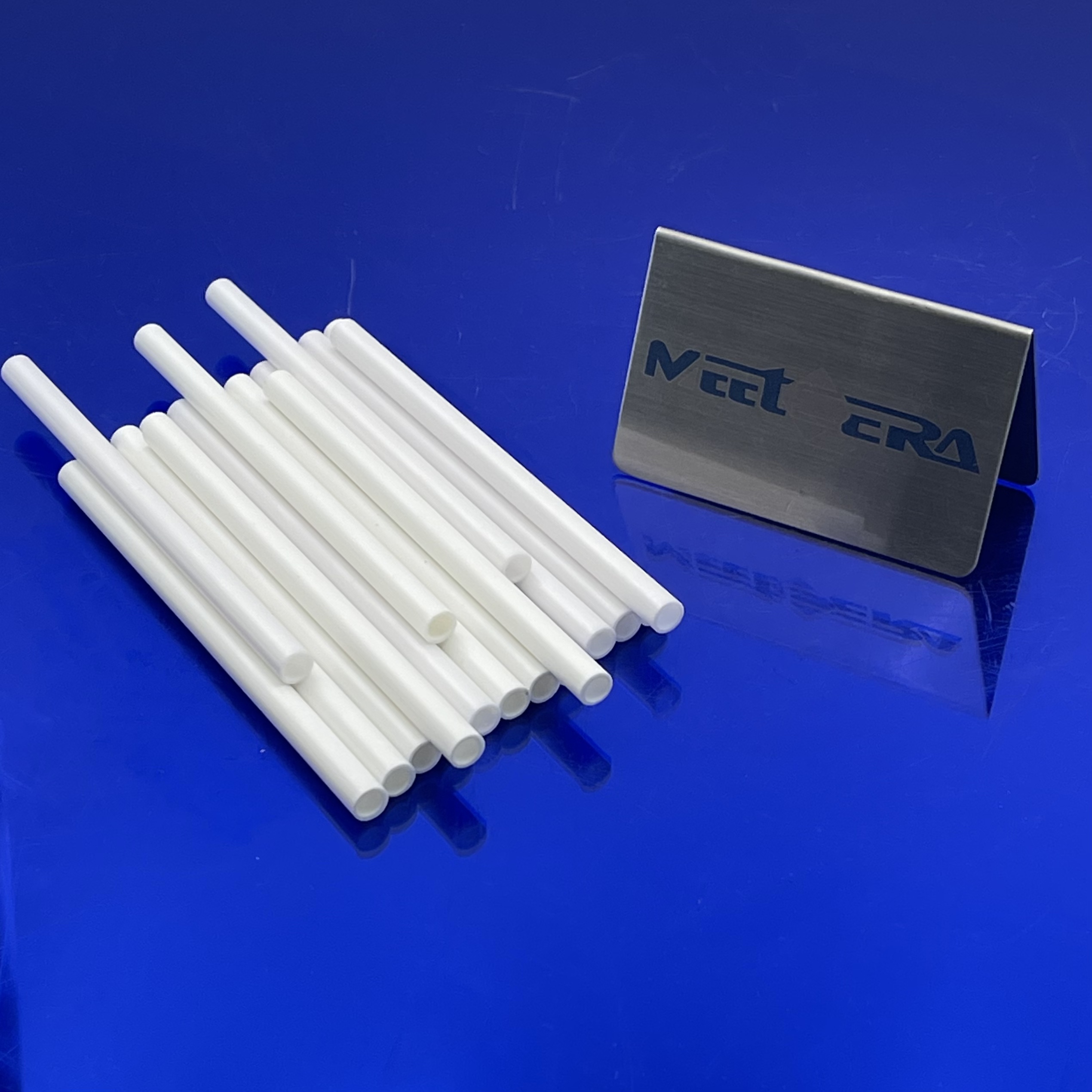

Alumina ceramic through-tubes for Size specifications:

The pipe diameter is small. Usually, its outer diameter can be as small as a few tenths of a millimeter or even thinner. The inner diameter is correspondingly narrow. The length can be customized according to specific needs, ranging from a few centimeters to several tens of centimeters. Such a small size enables it to be applied in some precision and miniaturized filtration and fluid transportation devices, such as fluid channels in microchemical analysis instruments and material transportation pipelines in small bioreactors.

-

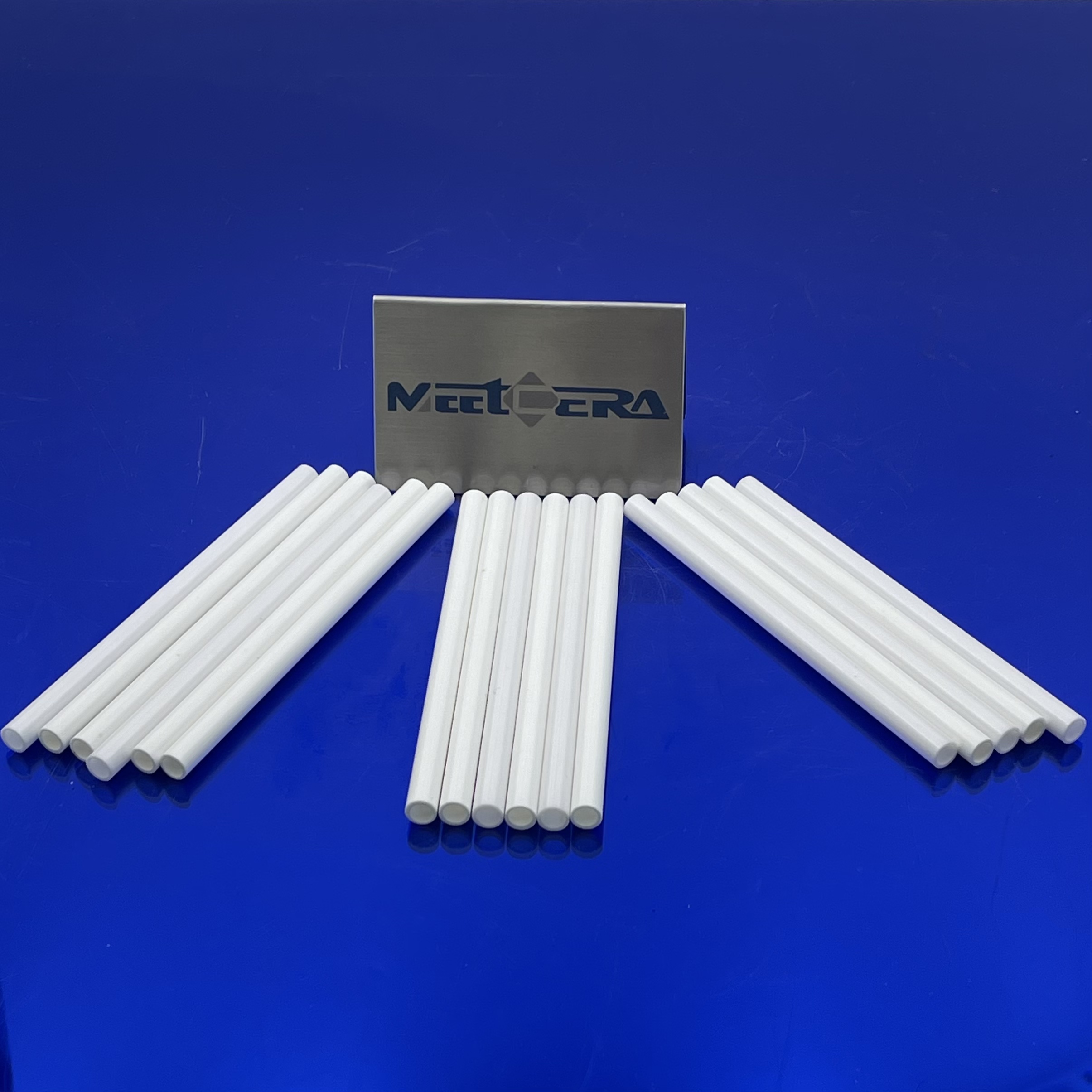

Density and hardness of alumina ceramic through-tubes:

It has a high hardness, with a Mohs hardness of about 9. The texture is hard and has good wear resistance. It is not easily scratched or worn during normal use and can maintain the integrity and dimensional accuracy of the pipe body for a long time. Its density is generally around 3.9 – 4.1 g/cm³. While having a certain mass, the structure is relatively dense.

– Alumina ceramic through-tubes have chemical stability:

The chemical properties are very stable. It has strong corrosion resistance to most common chemical substances such as acids, alkalis, and salts. It can work normally in a wide pH range chemical environment and will not easily react with the contacted chemical substances, thus ensuring the lasting stability of its performance. It can be applied in various complex chemical systems. For example, it can be used as a transportation pipeline for special reagents in chemical synthesis and as a fluid channel in analysis and detection equipment with corrosive media.

– Alumina ceramic through-tubes have oxidation resistance :

In an oxidizing environment such as air and oxygen, even if exposed for a long time, it is not easy to undergo an oxidation reaction. It can maintain its own chemical structure and physical properties unchanged, further ensuring its service life and reliability in different application scenarios.

- Alumina ceramic through-tubes have high temperature resistance :

It can withstand relatively high temperatures. Generally, it can work stably in a high-temperature environment above 1000°C. Some high-quality alumina through pipes can even withstand high temperatures close to their melting point (about 2050°C). This makes it have excellent application potential in high-temperature process processes, such as high-temperature kiln exhaust pipelines and fluid channels in high-temperature heat exchangers. It will not soften or deform and affect normal use due to high temperatures.

- Alumina ceramic through-tubes have thermal conductivity:

The thermal conductivity is relatively moderate and has certain characteristics in heat transfer. It can help transfer heat in some scenarios that require appropriate heat dissipation. It can also cooperate with other insulation or heat preservation measures in applications with strict temperature control requirements to maintain the temperature stability of the fluid inside the pipeline or the surrounding environment. For example, it can play a role in the heat conduction channels of some micro heating devices.

|

|

|

Property

|

Unit

|

92% Alumina Ceramic

|

95% Alumina Ceramic

|

99% Alumina Ceramic

|

|

Density

|

g/cm3

|

≥3.63

|

≥3.68

|

≥3.83

|

|

Water absorption

|

%

|

O

|

O

|

O

|

|

Sintering temperature

|

°C

|

1500-1700

|

1600-1800

|

1700-1800

|

|

Hardness

|

HV

|

≥1400

|

≥1500

|

≥1650

|

|

Flexural strength

|

Kgf/cm2

|

3000

|

3000

|

3000

|

|

Compressive strength

|

Kgf/cm2

|

24000

|

25000

|

26000

|

|

Fracture toughness

|

Map.m3/2

|

3~4

|

3~4

|

4~5

|

|

Maximum temperature

|

°C

|

1600

|

1700

|

1800

|

|

Coefficient of thermal expansion

|

/°C

|

8*10-6

|

8*10-6

|

8*10-6

|

|

Heat shock

|

T(°C)

|

220

|

220

|

220

|

|

Thermal conductivity

|

W/m.k(25-300°C)

|

25 14

|

25 14

|

25 14

|

|

|

20°C

|

|

|

>1012

|

>1012

|

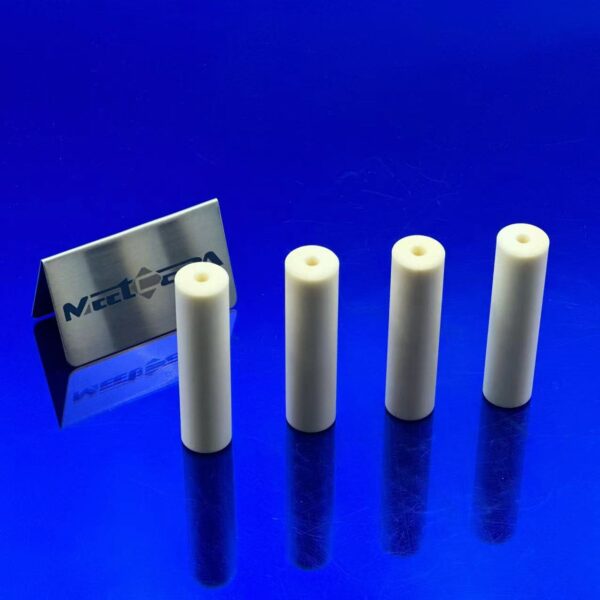

– Alumina ceramic through-tubes have strength and toughness:

Although alumina ceramics itself is a brittle material, this small through pipe still has a certain mechanical strength under reasonable design and manufacturing processes and can withstand a certain range of pressure. For example, it can work normally in some low-pressure or medium-low-pressure fluid transportation scenarios. However, its toughness is relatively low. When subjected to large external impacts or improper operations such as excessive bending, it is easy to break. Therefore, care should be taken to avoid such external forces during use and installation.

– Alumina ceramic through-tubes have fatigue resistance :

Under repeated stress, as long as the stress is within a reasonable limit, it can maintain good fatigue resistance and stably perform its function as a through pipe for a long time. For example, in some small fluid transportation equipment that works periodically, the stress changes caused by multiple openings and closings will not easily cause damage.

- Alumina ceramic through-tubes have insulation:

It is an excellent electrical insulation material with extremely high resistivity and excellent performance in electrical insulation. It can be applied in electrical equipment with strict requirements for electrical insulation, such as in heat dissipation and insulation channels of some electronic components and insulation protection pipelines in high-voltage electrical devices, effectively preventing current leakage and electrical short circuits.

– Alumina ceramic through-tubes have biocompatibility :

It has good biocompatibility and basically has no toxic or irritating adverse effects on organisms. Therefore, it can be used in biomedical fields. For example, it can be used in pipelines of some implantable micro drug delivery devices and fluid channels in biosensors to meet the requirements of biological safety and ensure the safety and effectiveness when in contact with biological tissues.

- Smoothness and friction coefficient of Alumina Ceramic Tubes:

The inner wall of the pipe is usually relatively smooth with low surface roughness. The friction coefficient when fluid flows through is small. This makes the resistance of fluid flowing inside the pipe relatively small, enabling it to pass through the pipeline more smoothly and helping to improve fluid transportation efficiency. Whether transporting gas or liquid, it can reduce energy loss and pressure drop caused by friction. It has obvious advantages in scenarios such as micro fluid analysis systems and fine chemical fluid transportation.

- Permeability and sealing performance of Alumina Ceramic Tubes:

It has a dense structure and very low permeability, which can effectively prevent fluid leakage and ensure good sealing performance. When used in occasions that require strict control of fluid flow and prevention of leakage, such as pipelines connecting different components in some high-precision analysis instruments and microchannels in microfluidic chips, it can reliably perform its functions.

Alumina ceramic through-tubes for physical properties

Alumina ceramic through-tubes for physical properties Chemical Properties of Aluminum Oxide Ceramic Through Tubes

Chemical Properties of Aluminum Oxide Ceramic Through Tubes Thermal properties of alumina ceramic through-tubes

Thermal properties of alumina ceramic through-tubes