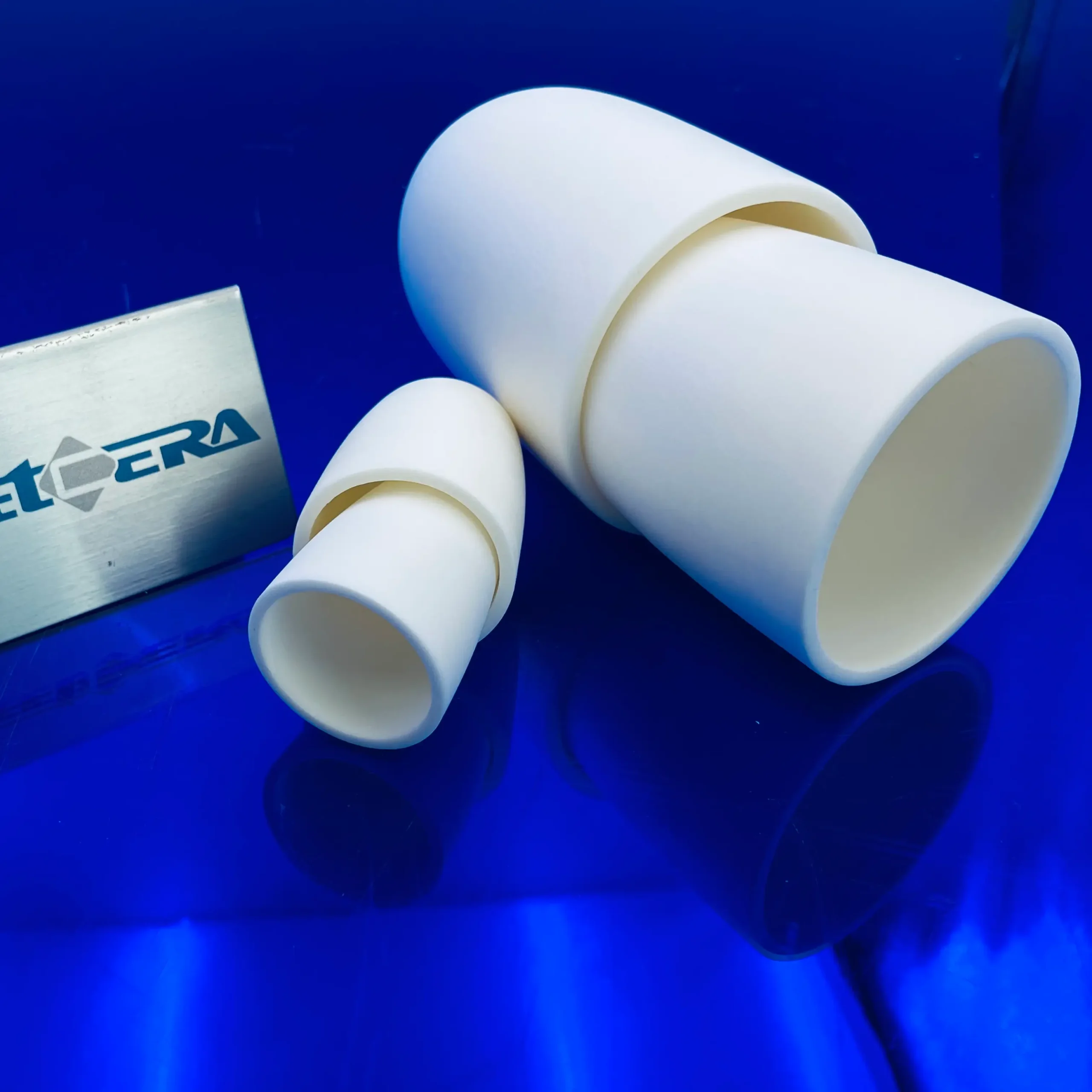

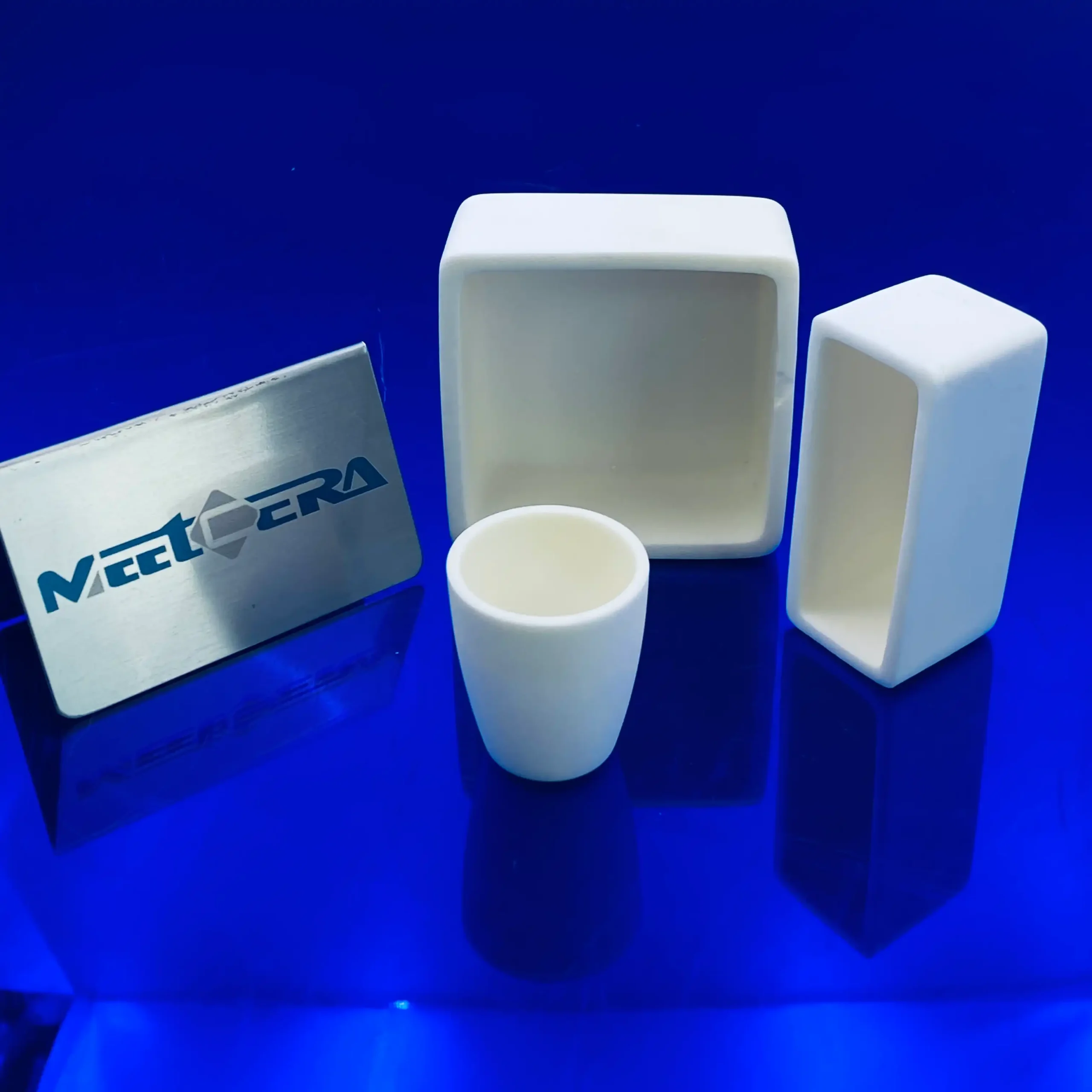

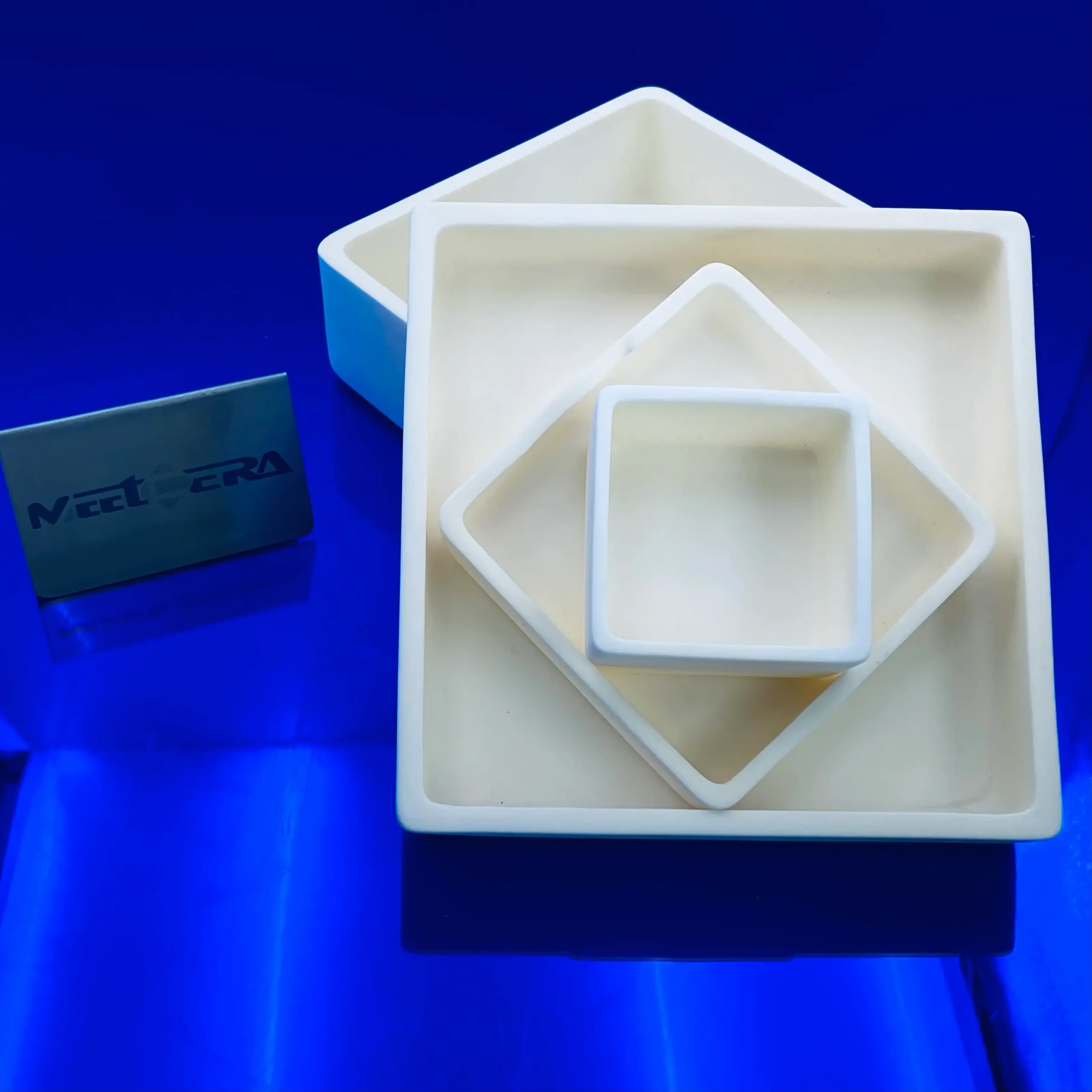

Alumina Ceramic Crucibles

Alumina Ceramic Crucibles are manufactured for more than 20 years and have a skill production technology in different shapes and range of sizes from few milliliters to several liters, these fully dense, high purity an high temperature use,fine grain products find use in a range of high temperature applications such as metal processing / molten glass, rapid thermal cycling, gemstone purification for jewelry industry etc. Majodrity of applications require the ceramic to be impervious, porous forms can also be made on order.

Alumina ceramic crucibles include:

Overview of Physical Properties:

Main Applications:

- Laboratory analysis and testing (e.g., TGA, DSC thermal analysis)

- Metal melting and processing

- Molten glass experiments

- Gemstone/jewelry industry purification and refining

- Rapid high-temperature thermal cycling

- Other high-temperature chemical reactions and material synthesis

FAQ

Q1: Alumina or zirconia – which to choose?

A: Choose 99% alumina for ≤1800°C and best value; select zirconia for >1800°C or extreme thermal shock.

Q2: How many uses and how to clean?

A: 50–200+ cycles typical. Clean with dilute acid soak, ultrasonic, DI water rinse, then dry at 100–150°C. Avoid strong alkalis/HF.

Q3: Lids available? Minimum order?

A: Yes, same-material lids for most shapes. MOQ: 10–50 pcs for standard sizes; 5–20 pcs for custom.