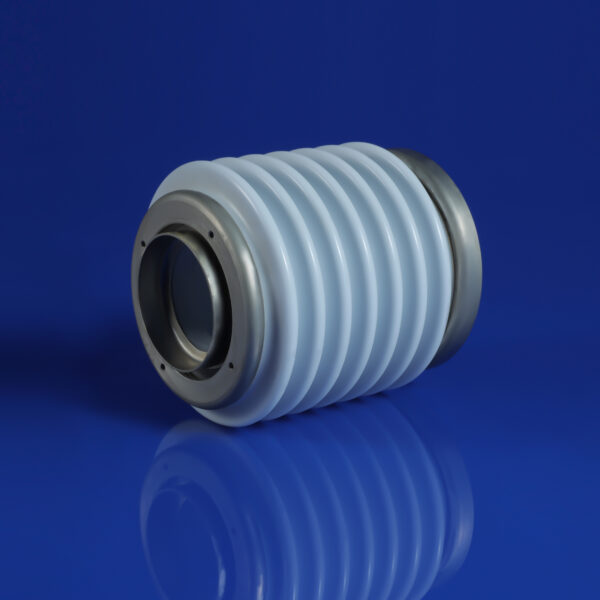

Ceramic-to-metal sealing products

MEETCERA offer customers a wide variety of vacuum-tight, hermetically sealed ceramic-to-metal components. Ceramic-to-metal sealing products not only have the characteristics of ceramic high temperature resistance, corrosion resistance, but also have the strength and toughness of metal. They are widely used in electronic aerospace, medical industry and other applications.

The best customer service and effcient solution could be provided is MEETCERA commitment.

The best customer service and effcient solution could be provided is MEETCERA commitment.

Ceramic-to-Metal Sealing Features:

- High Abrasion Resistance

- High Mechanical Strength

- Pressures over 10,000 PSI

- High Temperature Usage

- Low Dielectric Loss

- Mass Spectrometer Leak Tested

- High Chemical Stability

Ceramic-to-Metal Welding Process:

- Cleaning

- Pasting

- Metallizing

- Nickel Plating

- Mounting

- Welding

- Inspection&Packing

Ceramic-to-Metal Sealing Applications:

- Relay Insulators

- Capacitor

- Magnetrons

- Travelling Wave Tube

- X-ray Tube Components

- Electrosurgical Instrumentation

- Implantable Packages and Feedthroughs

- Gas Detectors

- Microscopes (TEM, SEM)

- High Voltage Feedthroughs

- High-temperature Feedthroughs

- RF Feedthroughs

- Optoelectronics and Power Tube

- Laser Tubes

- Thyristors

- Diodes

- And etc

FAQ

Q.What is the purpose of metallization?

A.It enables strong brazing/soldering of ceramics to metals, creating reliable hermetic seals and electrical connections in high-vacuum or high-voltage applications.

Q.Why use Molybdenum-Manganese (Mo/Mn) as the base coating?

A.Mo/Mn provides excellent adhesion to alumina through high-temperature sintering, ensuring high bond strength and reliability.

Q. Do you offer custom metallized ceramics?

A.Yes, we produce fully customized components based on your drawings, samples, or specific requirements.

For detailed technical data, quotations, please contact us directly. Meetcera is committed to delivering innovative, high-quality solutions for your most challenging applications.