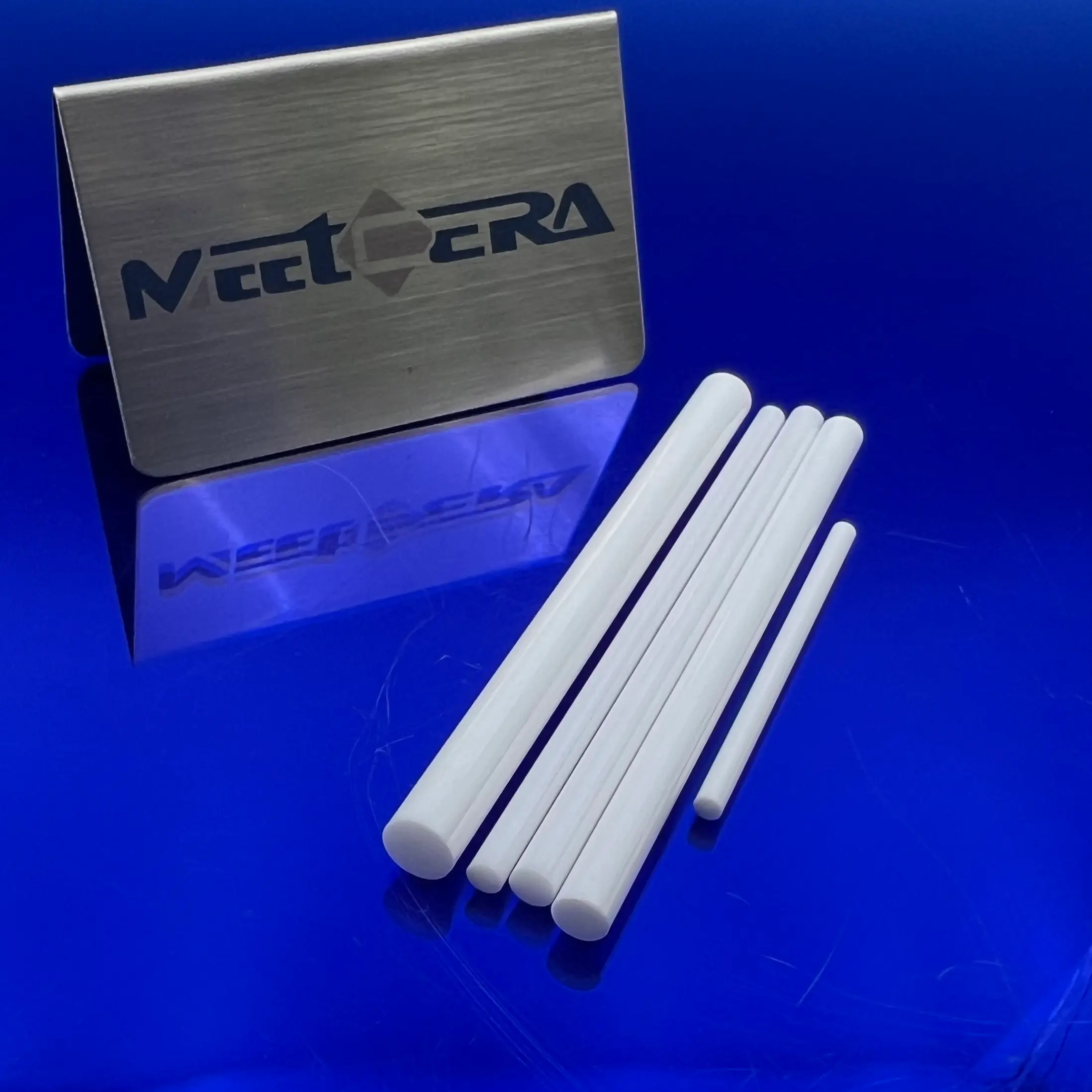

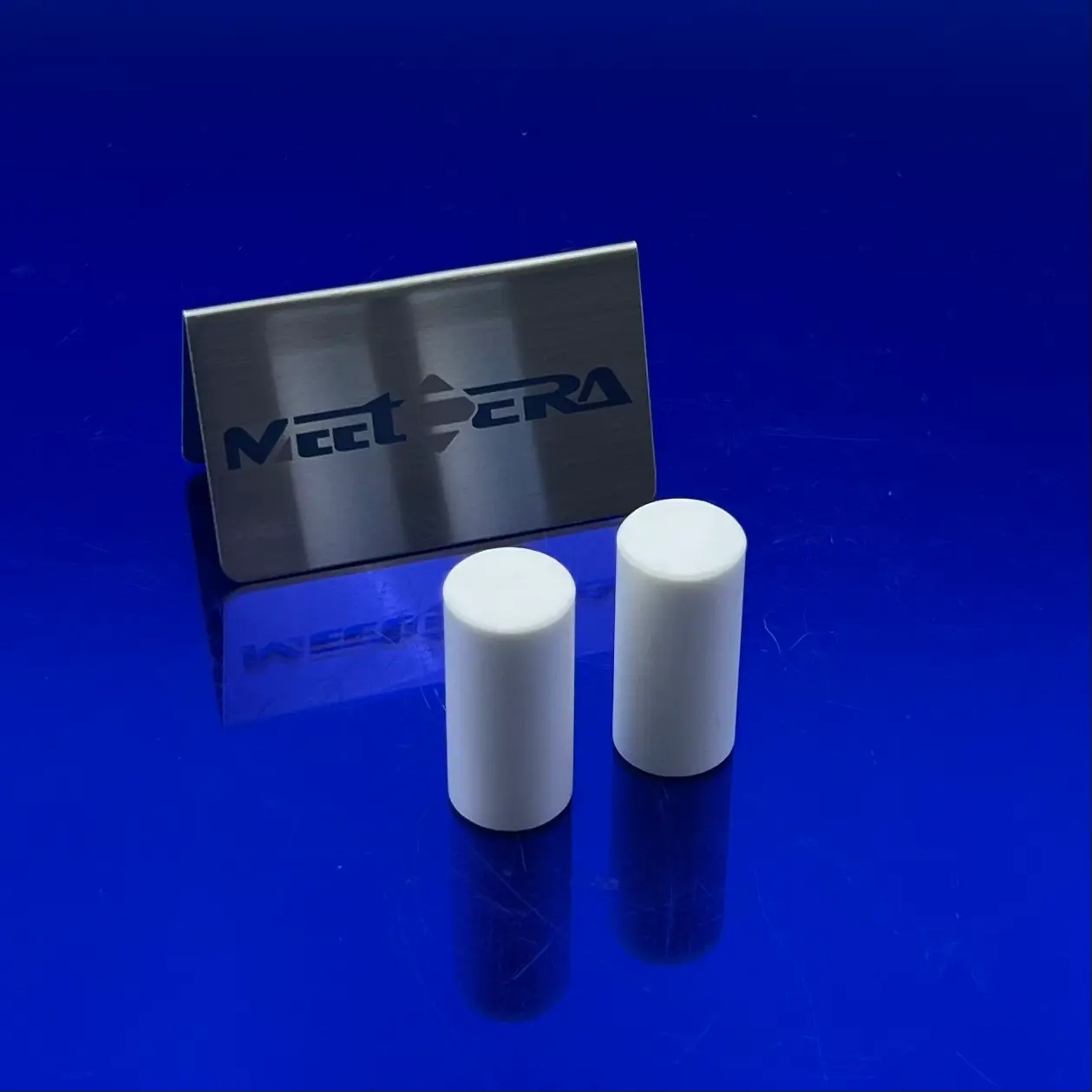

High-Purity 99% Alumina Ceramic Rod

The 99% alumina ceramic rod (Alumina Ceramic Rod) is a rod-shaped precision ceramic product made from high-purity alumina (Al₂O₃ content ≥99%) as the main raw material through advanced sintering processes. It is widely used in semiconductors, electronics, chemicals, machinery, high-temperature furnaces, and other fields, known as the "secret weapon" in industrial applications. Our 99% alumina ceramic rods offer superior mechanical strength, thermal stability, and chemical inertness, enabling long-term stable operation in extreme environments. They are an ideal alternative to traditional metal materials.

Key Features:

- Extremely High Hardness and Wear Resistance: Mohs hardness of 9, second only to diamond; surface can be polished to a mirror finish with low friction coefficient, suitable for high-wear environments such as bearings, seals, and grinding wheels.

- Outstanding High-Temperature Performance: Maximum service temperature up to 1700°C or higher, low thermal expansion coefficient, strong thermal shock resistance; ideal for high-temperature furnace tubes, thermocouple protection tubes, and radiation tubes.

- Excellent Electrical Insulation: High resistivity and low dielectric loss, effectively preventing current leakage even at high temperatures; widely used in insulating rods, supports, and high-voltage electrical equipment.

- Superior Corrosion Resistance: Resistant to acids, alkalis, steam, and most chemicals; suitable for chemical reactors, laboratory instruments, and corrosive media environments.

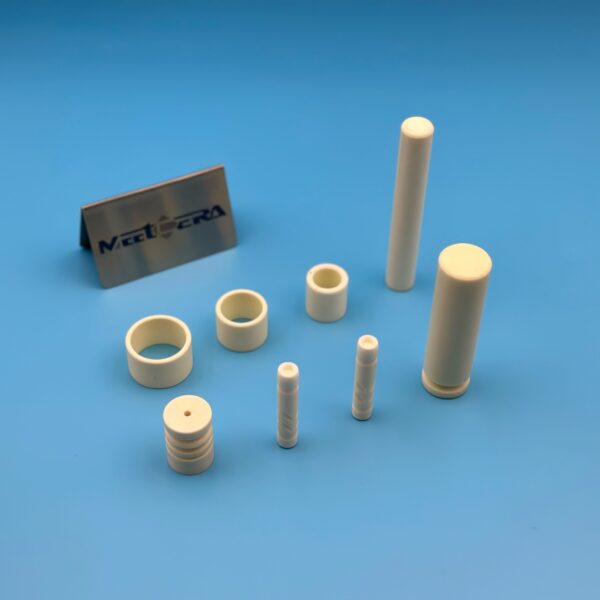

- High Purity and Precision Machining: Al₂O₃ content up to 99%, supporting custom diameters, lengths, and shapes (e.g., single-hole, multi-hole, or special shapes); high dimensional accuracy and controllable straightness.

Application Areas:

- Semiconductor and Electronics Industry: Used in CVD equipment, ion implantation, lithography machine parts, insulating substrates, and probes.

- High-Temperature Industry: Furnace rollers, heating element supports, protection tubes, and refractory materials.

- Mechanical Engineering: Wear-resistant shafts, plungers, sliding bearings, and precision guides.

- Medical and Laboratory: Good biocompatibility, used in surgical tools and analytical instruments.

- Aerospace and Chemical: High-temperature structural components and corrosion-resistant parts.

Frequently Asked Questions (FAQ)

1.What is the maximum service temperature of the 99% alumina ceramic rod?

Our high-purity 99% alumina ceramic rods can withstand temperatures up to 1700°C or higher, with long-term use in oxidizing atmospheres up to 1650°C. Consider thermal shock risks in practice and avoid rapid heating or cooling.

2.Does the 99% alumina ceramic rod support custom machining?

Yes, we offer highly customized services, including diameters (3-50mm), lengths (up to 2500mm), shapes (single-hole, multi-hole, special shapes), surface polishing, drilling, slotting, chamfering, and other precision machining. Please provide drawings or specific requirements for a quote.

3.What are the differences between 99% alumina ceramic rods and zirconia ceramic rods?

99% alumina ceramic rods have higher hardness (Mohs 9), better wear resistance, lower cost, and superior insulation performance, making them suitable for high-temperature insulation and wear-resistant environments. Zirconia ceramic rods offer better toughness and thermal shock resistance, ideal for applications requiring higher impact resistance or frequent thermal cycling. Choose based on the specific application scenario.

Choose our 99% alumina ceramic rods for reliable performance and customized services. We support a wide range of specifications—welcome to provide drawings for consultation and quotes! If you have other questions or need more technical parameters, feel free to contact us. We offer professional technical support and fast quoting services.