Alumina Ceramic Components

Alumina ceramic (Al₂O₃) is one of the most widely used advanced ceramics. It combines excellent electrical insulation with extreme wear resistance, corrosion resistance, and mechanical strength. Shaped only by precision methods like diamond grinding, it has a melting point of 2072°C and hardness near Mohs 9. Essential for electronics, pumps & valves, automotive sensors, and more.

Key Features & Advantages:

- Superior electrical insulation (DC to GHz)

- Low dielectric constant & low loss tangent

- Exceptional hardness and wear resistance

- Excellent corrosion resistance (strong acids/alkalis)

- High thermal stability and temperature resistance

- Strong mechanical strength & rigidity

- Joinable to metals/other ceramics via metallization + brazing

- Customizable via purity levels and forming methods

Main Application Areas & Typical Products:

Wear-Resistant Components

- Ceramic Nozzles

- Ceramic Sprayer Cyclones

- Homogenizing Devices

- Ceramic Linings

- Milling System Parts

- Ceramic Thread / Wire Guides

Precision Components

- Ceramic Measuring Parts

- Ceramic Control System Parts

- Micro Dosing Valves

- Electronic Substrates & Insulators

- Optical / Optoelectronic Parts

- Mechatronics Components

Mechanical & Machine Tool Applications

- Positioning & Guide Parts

- Ceramic Coatings

- Transport Ceramic Rollers

- Ceramic Dies / Punches

- Textile Machine Parts

- Furnace / Kiln Components

Rotating Equipment & Sealing

- Ceramic Sliding Bearings

- Ceramic Ball Bearings

- Mechanical Seal Rings

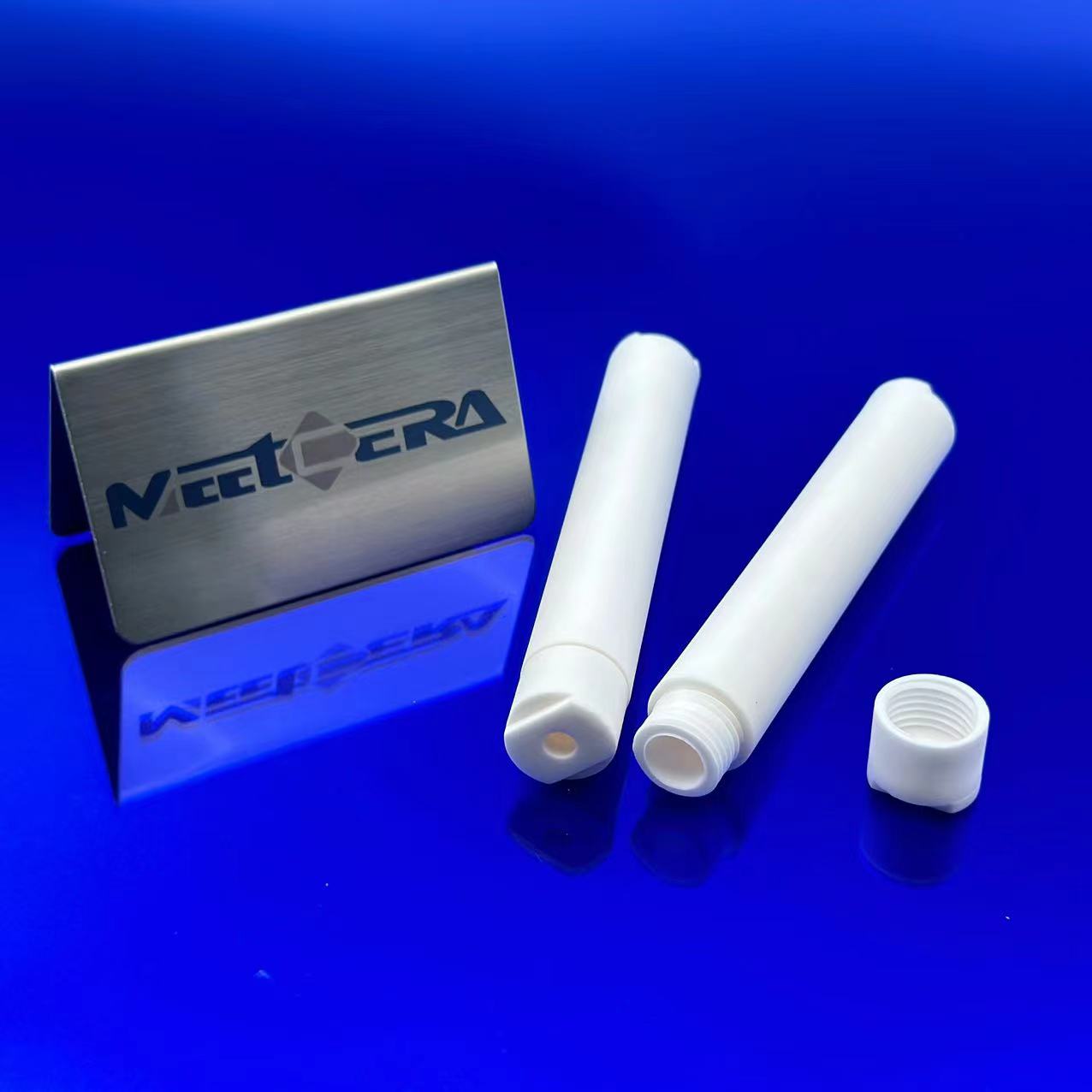

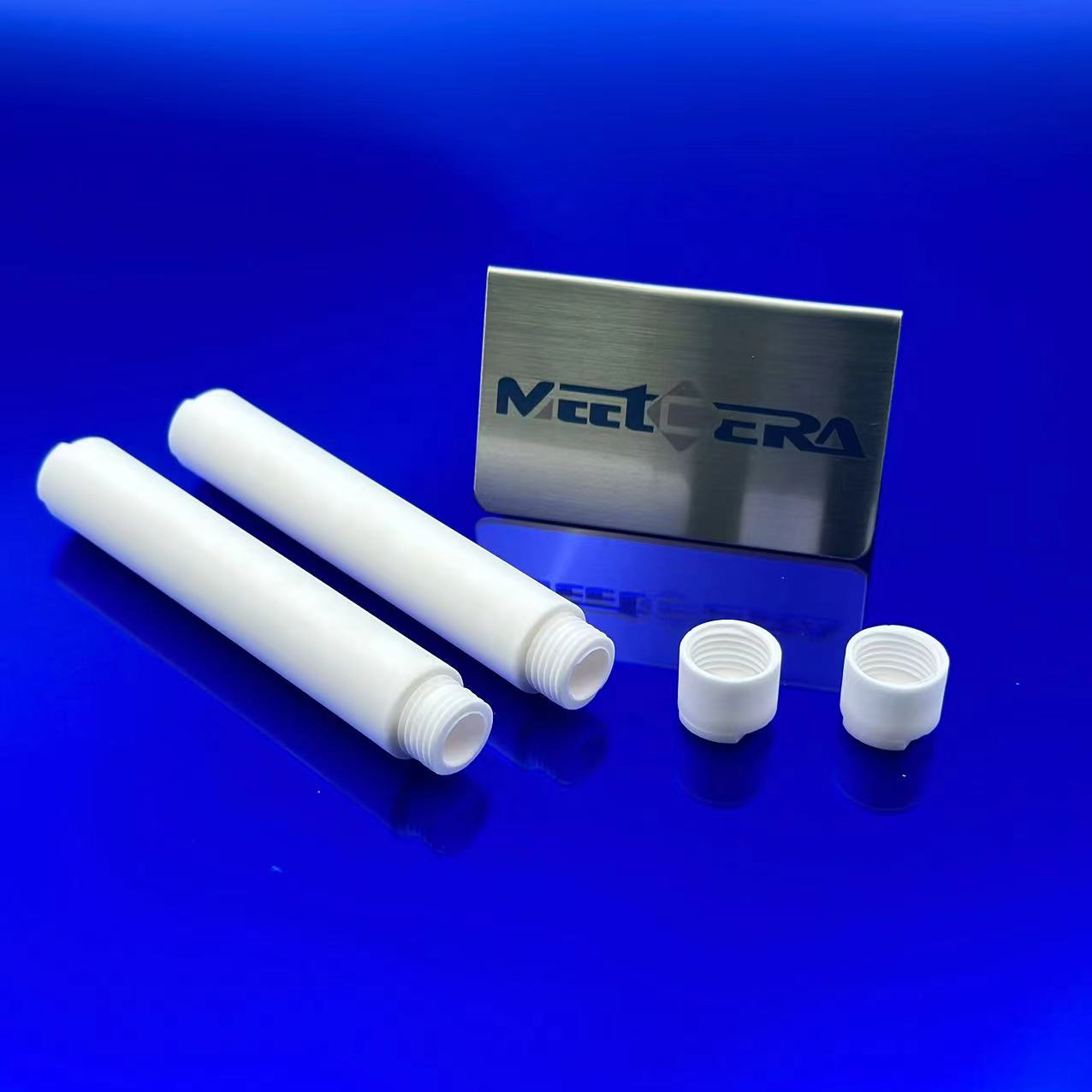

- Ceramic Plungers

- Ceramic Valves / Fittings

- Dosing / Metering Components

Cutting & Forming Tools

- Ceramic Knives

- Metal-Forming Tools

- Seaming Rolls

- Ceramic Punches

- Drawing Dies

Other Classic Applications

- Seal Rings

- Medical Prostheses

- Laser Tubes

- Electronic Substrates

- Ballistic Armour

- Thermocouple Protection Tubes

- Electrical Insulators

- Grinding Media

Frequently Asked Questions (FAQ)

1.Is alumina ceramic a good electrical insulator?

Yes — excellent insulation from DC to GHz, ideal for substrates, insulators, and high-voltage parts.

2.How does purity affect performance?

Higher purity (99%+) gives better hardness, wear, corrosion, and heat resistance — best for medical, semiconductor, high-temp uses. 90–98% offers great value for general industrial applications.

3.Is alumina ceramic safe / non-toxic for medical or food use?

Yes, it is chemically inert and generally non-toxic. High-purity grades are used in medical implants, but must meet relevant standards (e.g., ISO 10993) for each application.

Meetcera specializes in alumina ceramic R&D and production. We offer full customization based on your drawings, 3D models, or functional needs — from prototypes to mass production, including material selection, forming, diamond grinding, surface finishing, and assembly.