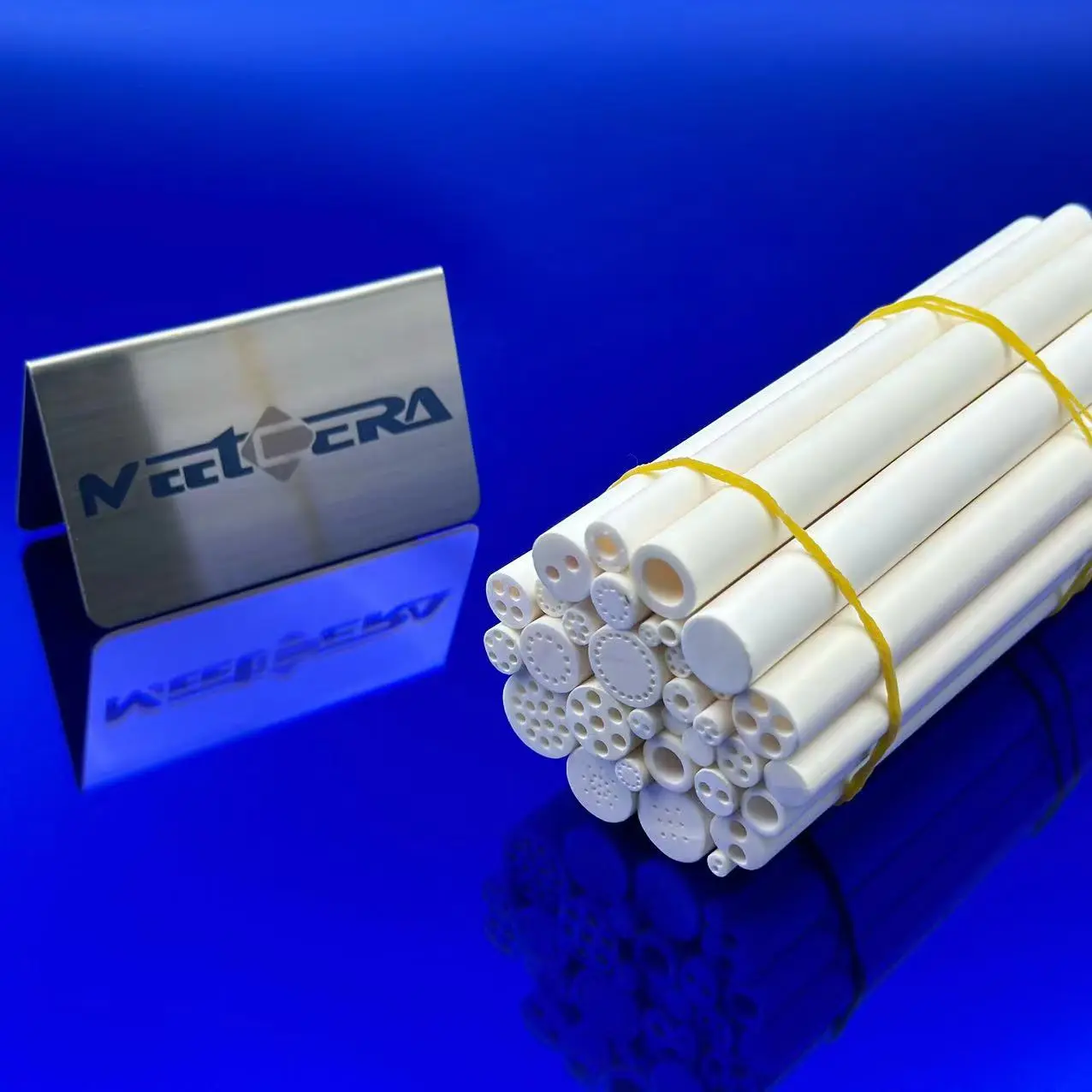

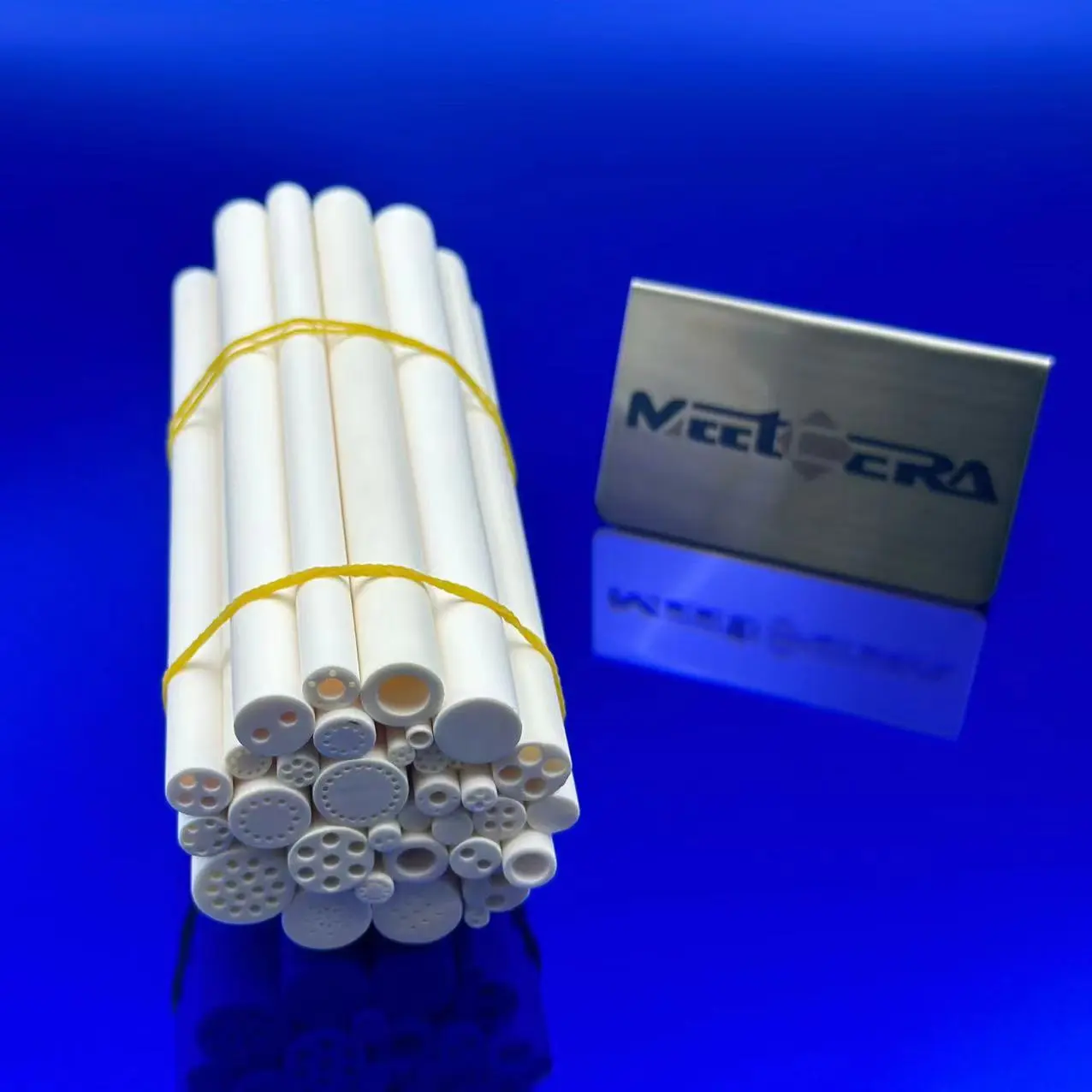

Alumina Multi Hole Ceramic Pipe and Tube

Our porous alumina tubes are manufactured using high-purity α-Al₂O₃ (alumina content ≥99%) as the primary material, through advanced sintering processes, resulting in a uniform and controllable porous structure. This product combines the excellent properties of alumina ceramics with the unique advantages of porous design, making it suitable for demanding environments such as gas/liquid filtration, diffusion, separation, and support. It is an ideal choice for industrial filtration, catalyst carriers, and high-temperature applications.

Key Features:

- High Temperature Resistance: Maximum operating temperature up to 1700°C or higher, with excellent thermal shock resistance.

- Superior Corrosion Resistance: Resistant to acids, alkalis, and chemical erosion, suitable for highly corrosive media.

- High Mechanical Strength: High compressive strength, hardness up to Mohs 9, wear-resistant, and long service life.

- Controllable Porous Structure: Uniform pore size (customizable in 5-100μm range), high porosity for efficient permeability and filtration precision.

- Excellent Insulation: Outstanding electrical insulation and low thermal expansion coefficient.

- Environmentally Friendly and Non-Toxic: Good biocompatibility, no release of pollutants.

| Parameter | Specification/Range | Remarks |

|---|---|---|

| Material Purity | 99% ~ 99.8% Al₂O₃ | High-purity α-alumina |

| Density | 3.0 ~ 3.9 g/cm³ | Adjusted based on porosity (lower than dense alumina due to pores) |

| Porosity | 30% ~ 50% | Adjustable |

| Pore Size Range | 1 ~ 200 μm | Customized per application |

| Outer Diameter/Inner Diameter/Length | Various specifications supported (e.g., OD 10-100mm, length 100-2000mm) | Fully customizable |

| Color | White | - |

Application Areas:

- Filtration and Separation: Gas/liquid filtration, cross-flow filtration, wastewater treatment, air purification.

- Catalyst Carrier: Automotive exhaust purification, industrial catalytic reactions, organic waste gas treatment.

- Gas Diffusion: Aerators, gas distributors, semiconductor process gas delivery.

- High-Temperature Support: Vacuum furnace tubes, thermocouple protection tubes, kiln insulation components.

- Battery and New Energy: Battery separators, fuel cell components.

- Others: Laboratory instruments, medical equipment, chemical pipeline linings, etc.

Advantages and Highlights:

Utilizing precision molding and sintering technology to ensure high dimensional accuracy and uniform structural stability. Compared to traditional metal or polymer materials, our porous alumina tubes perform superiorly in high-temperature and highly corrosive environments, with lower maintenance costs and longer service life. We support OEM customization services and can adjust pore size, dimensions, and performance parameters according to your specific needs.

Frequently Asked Questions (FAQ):

1. Does the product support customization of pore size and porosity?

Yes, we offer comprehensive customization services. Pore size ranges from 1μm to 200μm, and porosity from 30%-50% is adjustable. Please provide your application requirements, and we will optimize the parameters.

2. Is the porous alumina tube resistant to acid and alkali corrosion?

Yes, it has excellent resistance to acids, alkalis, and chemical corrosion, suitable for most strong corrosive media (such as acids, alkalis, seawater), but extremely strong oxidants require testing for confirmation.

3. How to clean and maintain the porous alumina tube?

It can be cleaned using ultrasonic cleaning, backflushing, or high-temperature sintering regeneration. Avoid strong mechanical scraping. Regular cleaning can extend service life, with specific methods depending on the application media.

Welcome to inquire about customization details. We are committed to providing high-quality, durable, and reliable ceramic solutions!