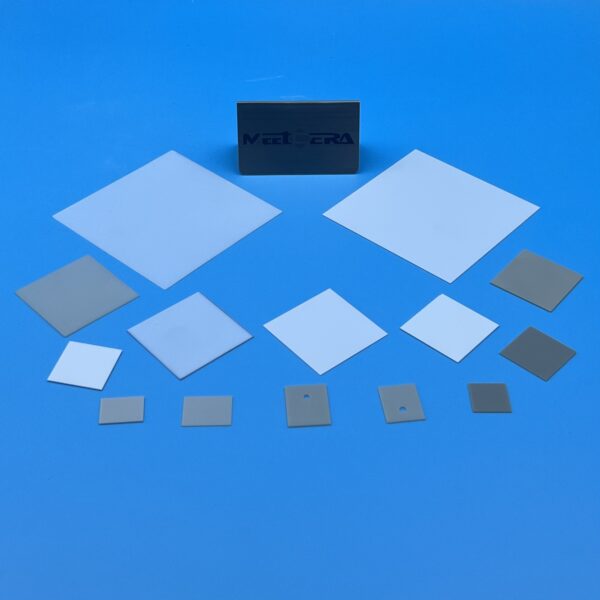

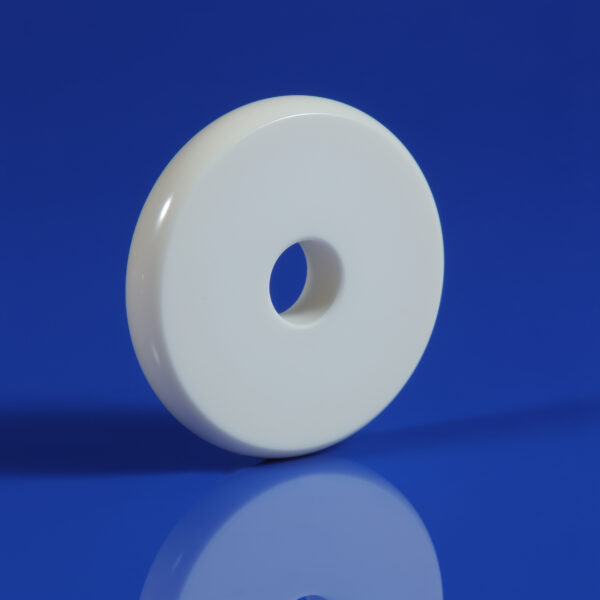

- High hardness and sharpness :

Textile ceramic blade discs are usually made of high-performance ceramic materials such as alumina and zirconia. These ceramic materials themselves have extremely high hardness and are at a relatively high position in the Mohs hardness scale, making the blade extremely sharp. For example, the hardness of alumina ceramics is second only to diamond. This allows the blade disc to easily cut into various textile materials.

- High strength and high toughness:

It has strong compressive, bending and impact resistance strength performance. During the cutting of textile materials, it needs to withstand the pressure applied during cutting and the resistance of the material itself. The ceramic blade disc will not easily crack or deform.

- Good wear resistance:

Since the cutting operation means long-term and frequent friction between the textile material and the blade, the textile ceramic blade disc, with its excellent wear resistance, can maintain a good state of the blade in a large number of cutting tasks. Compared with traditional metal blades, its wear rate is much slower.

- High temperature resistance:

In some textile processing scenarios, high temperature environments may be involved. For example, cutting after preheating the textile material, or continuous operation in a relatively hot production workshop environment. The ceramic materials selected for textile ceramic blade discs mostly have good high temperature resistance.

- Low density:

Compared with similar cutting parts made of some metal materials, the density of textile ceramic blade discs is usually lower. This characteristic means that when installed and used in textile equipment, it will not add excessive weight burden to the rotating system of the equipment, helping the flexible operation of the equipment, reducing the power consumption during equipment operation, and at the same time facilitating the overall structural layout and installation and debugging operations of the equipment.

- High surface smoothness:

After fine processing technology treatment, the surface of textile ceramic blade discs can reach a relatively high smoothness. This not only facilitates the smooth passage of textile materials through the blade during cutting, reducing phenomena such as jamming and adhesion, but also reduces the heat generated by friction and avoids adverse effects on the blade disc and textile materials due to heat accumulation, further improving the cutting efficiency and quality and ensuring the smoothness of the cut edge of textile materials.