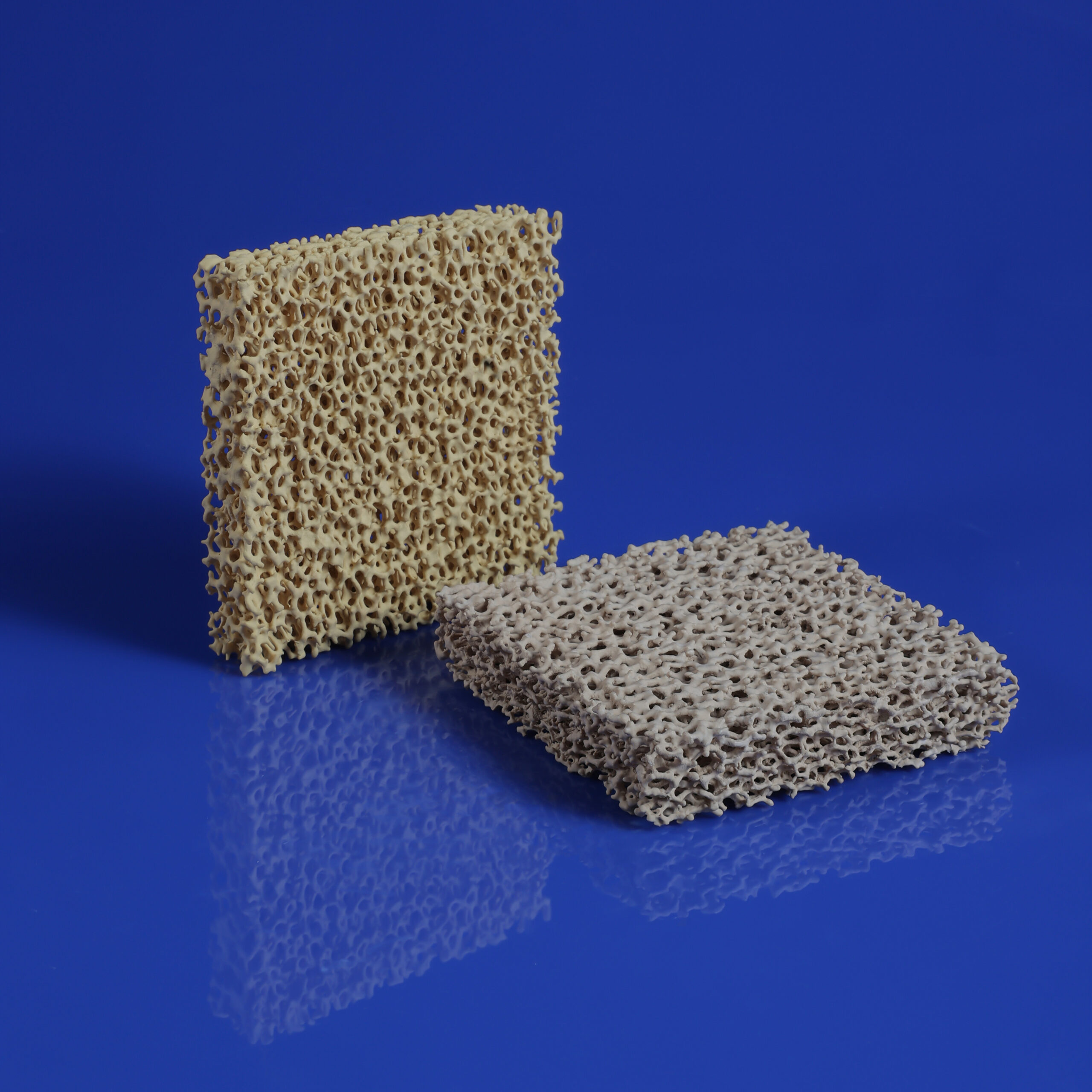

Porous Foam Ceramic Filter

Ceramic Foam Ceramic are mainly used for filtration of aluminium and aluminium alloys in foundries and cast houses . With theirexcellent thermal shock resistance and corrosion resistance from molten aluminum, they can effectively eliminate inclusions,reduce trapped gas and provide laminar flow, and then the filtered metal is significantly cleaner. Cleaner metal results inhigher-quality castings, less scrap, and fewer inclusion defects, all of which contribute to bottom-line profit.

Material | Alumina | Silicon Carbide | Zirconia | |

Color | White | Grey black | Yellow | |

Pore Density | 8-60ppi | 8-60ppi | 8-60ppi | |

Porosity | 80-90% | 80-90% | 80-90% | |

Refractoriness | ≤1100℃ | ≤1500℃ | ≤1700℃ | |

Bending Strength | >0.6Mpa | >0.8Mpa | >1.0Mpa | |

Compression Strength | >0.8Mpa | >0.9Mpa | >1.2Mpa | |

Volume-weight | 0.3-0.45g/cm³ | 0.35-0.5g/cm³ | 0.9-1.5g/cm³ | |

Thermal shock resistance | 6times/1100℃ | 6times/1100℃ | 6times/1100℃ | |

Application | Aluminium Aluminium alloys and other Non-ferrous alloys | Ductile Cast Iron Malleable Cast Iron Gray iron and other Cast Iron | High melting point metal alloys like Steel Alloy Steel Stainless Steel etc | |

Physical Properties | ||||

Working | ≤1200℃ | |||

Porosity | 80-90% | |||

Compression Strength (Indoor Temperature) | ≥1.0Mpa | |||

Volume Density | ≤0.5g/cm3 | |||

Thermal Shock Resistance | 800℃--Indoor Temperature 5 times | |||

Application | Non-ferrous and alumina alloys, high temperature gasfilter, chemical fillings and catalysis carrier | |||

Alumina Ceramic Foam Filter

Aluminum Ceramic Foam Filter are mainly used for filtration of aluminium and aluminium alloys in foundries and cast houses . With

their excellent thermal shock resistance and corrosion resistance from molten aluminum, they can effectively eliminate inclusions,

reduce trapped gas and provide laminar flow, and then the filtered metal is significantly cleaner. Cleaner metal results in

higher-quality castings, less scrap, and fewer inclusion defects, all of which contribute to bottom-line profit

their excellent thermal shock resistance and corrosion resistance from molten aluminum, they can effectively eliminate inclusions,

reduce trapped gas and provide laminar flow, and then the filtered metal is significantly cleaner. Cleaner metal results in

higher-quality castings, less scrap, and fewer inclusion defects, all of which contribute to bottom-line profit

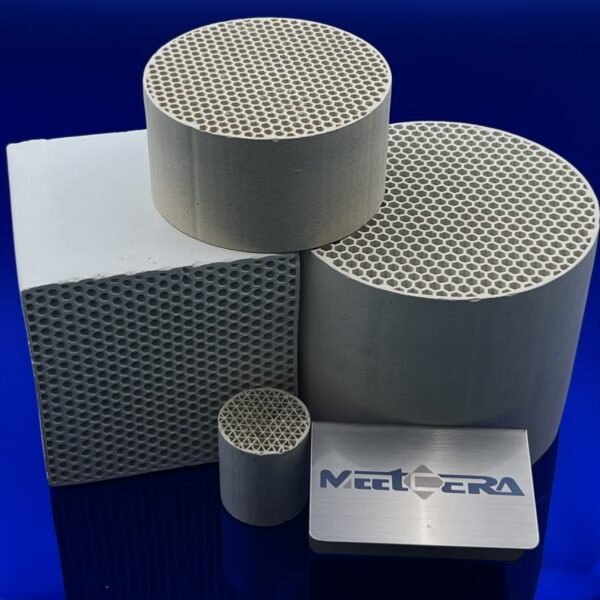

Silicon Carbide Ceramic Foam Filter

SIC Ceramic Foam Filter is a kind of effective molten metal filter. It's three-dimensional connected mesh structure and high

porosity has many advantages,for example, large surface area of slags collection. Large inner surface area of filtering.small flow

resistance.good filtering effect.etc. SIC Ceramic Foam Filter is one of the size ,the size can be customized.

porosity has many advantages,for example, large surface area of slags collection. Large inner surface area of filtering.small flow

resistance.good filtering effect.etc. SIC Ceramic Foam Filter is one of the size ,the size can be customized.

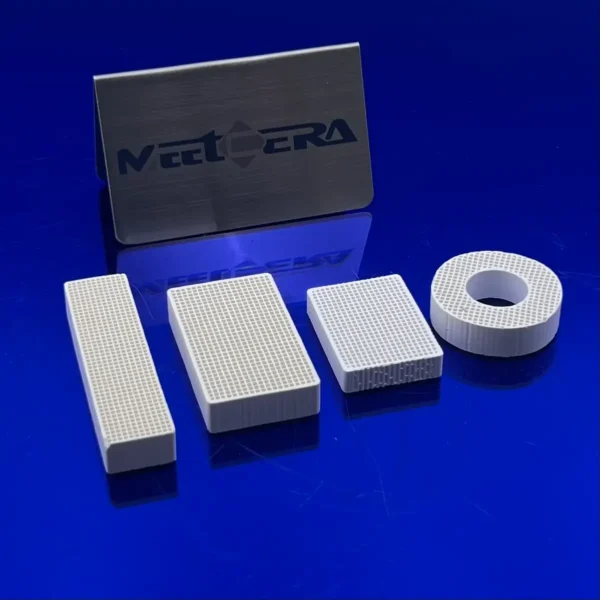

Zirconia Ceramic Foam Filter

Zirconia Ceramic Foam Filter is a phosphate-free, high metling point, It is characterized by high porosity and mechanochemical

stability and excellent resistance to thermal shock and corrosion from molten steel, It can effectively remove inclusions, reduce

trapped gas and provide laminar flow when molten zieconia foam filtrated, it is machined to tight dimensional tolerance during

production, this combination of physical properties and precise tolerance make them first choice for molten steel,alloy steel, and

stainless steel, etc

stability and excellent resistance to thermal shock and corrosion from molten steel, It can effectively remove inclusions, reduce

trapped gas and provide laminar flow when molten zieconia foam filtrated, it is machined to tight dimensional tolerance during

production, this combination of physical properties and precise tolerance make them first choice for molten steel,alloy steel, and

stainless steel, etc