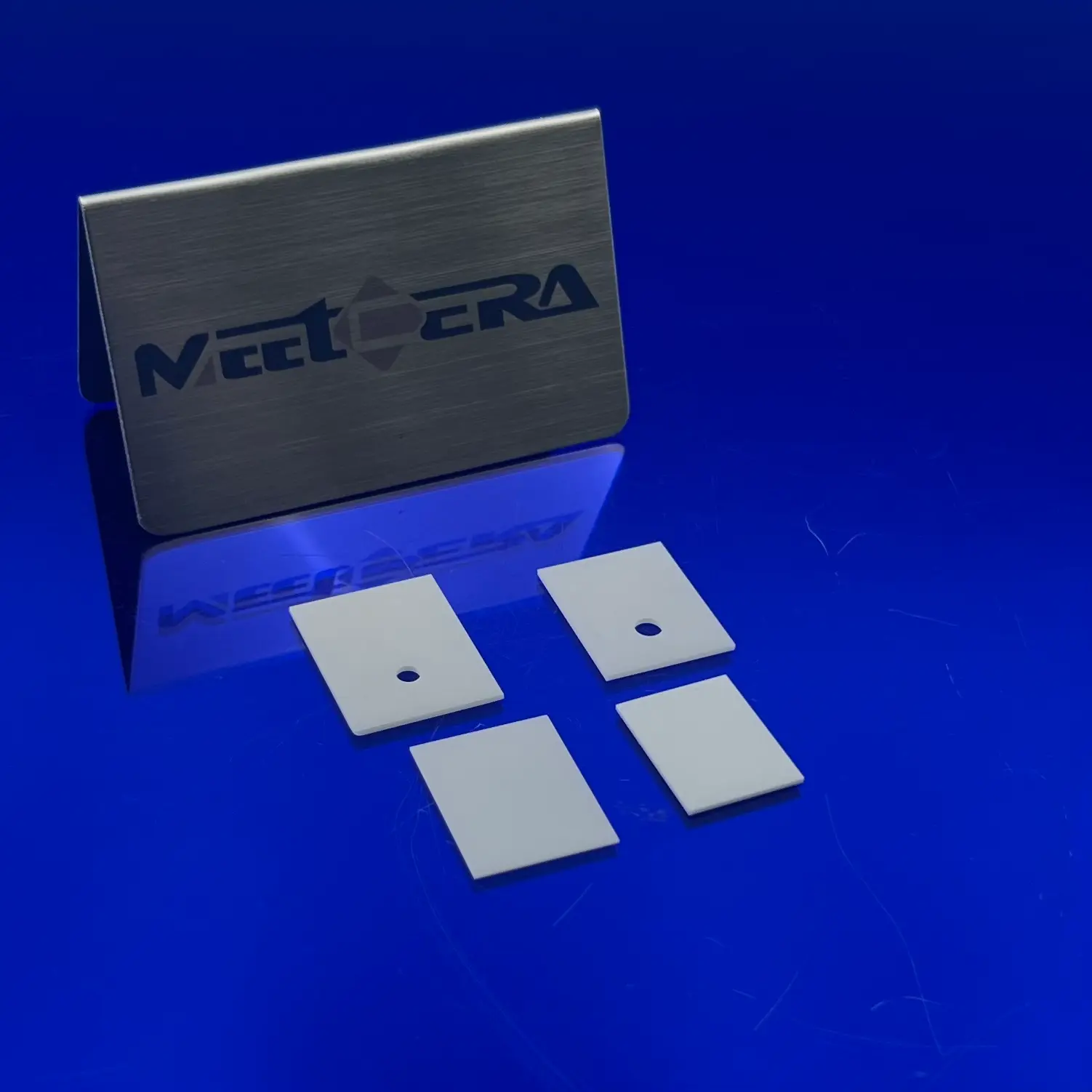

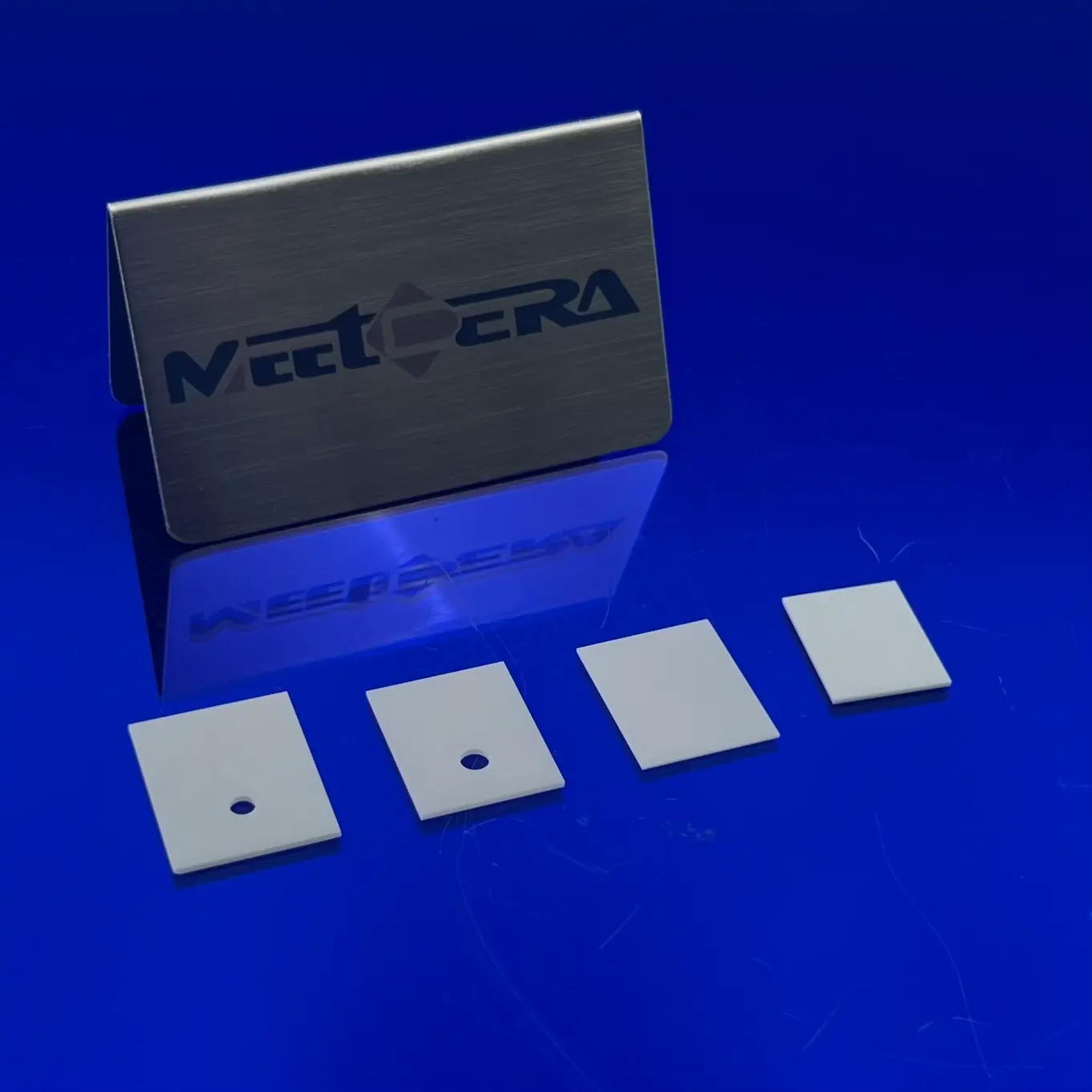

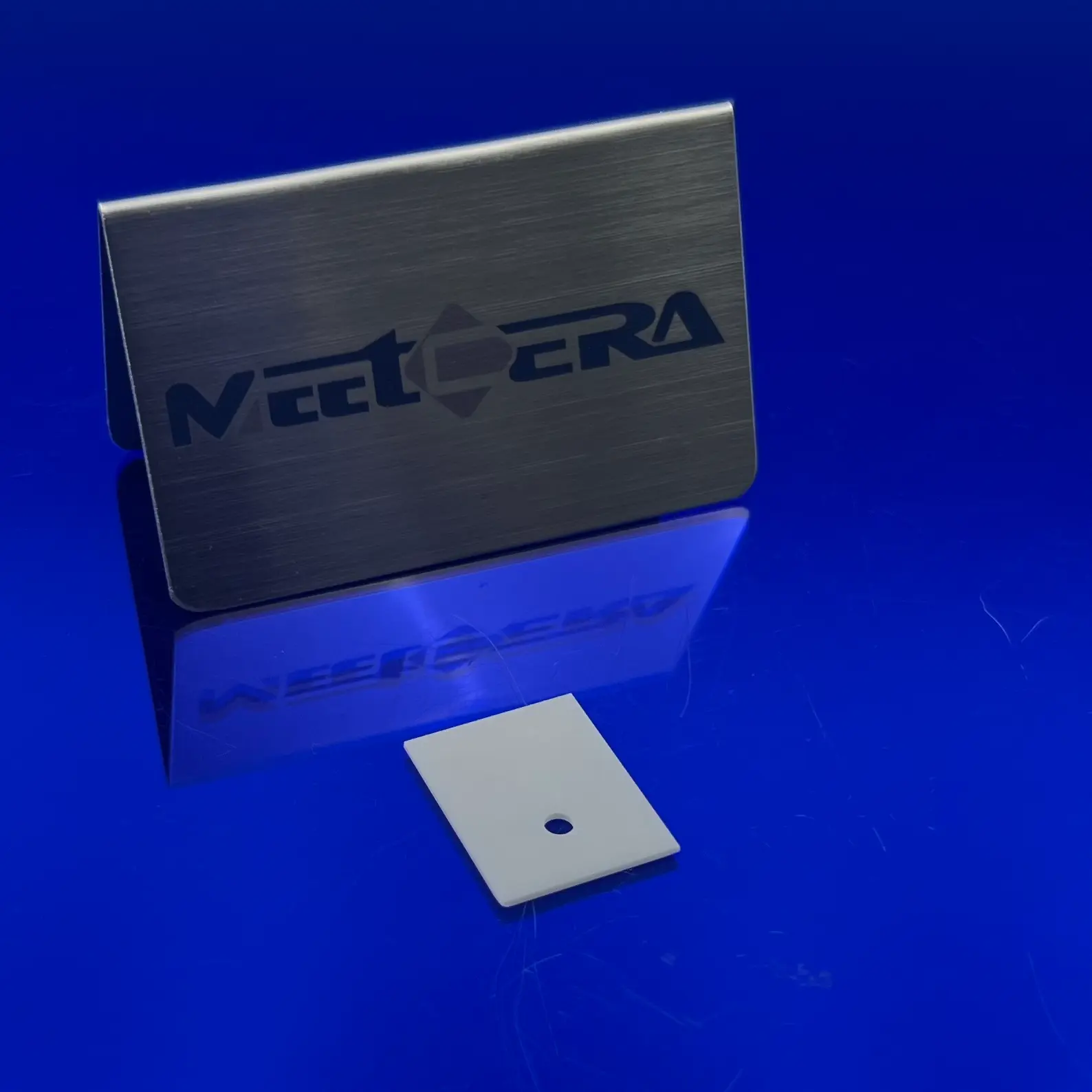

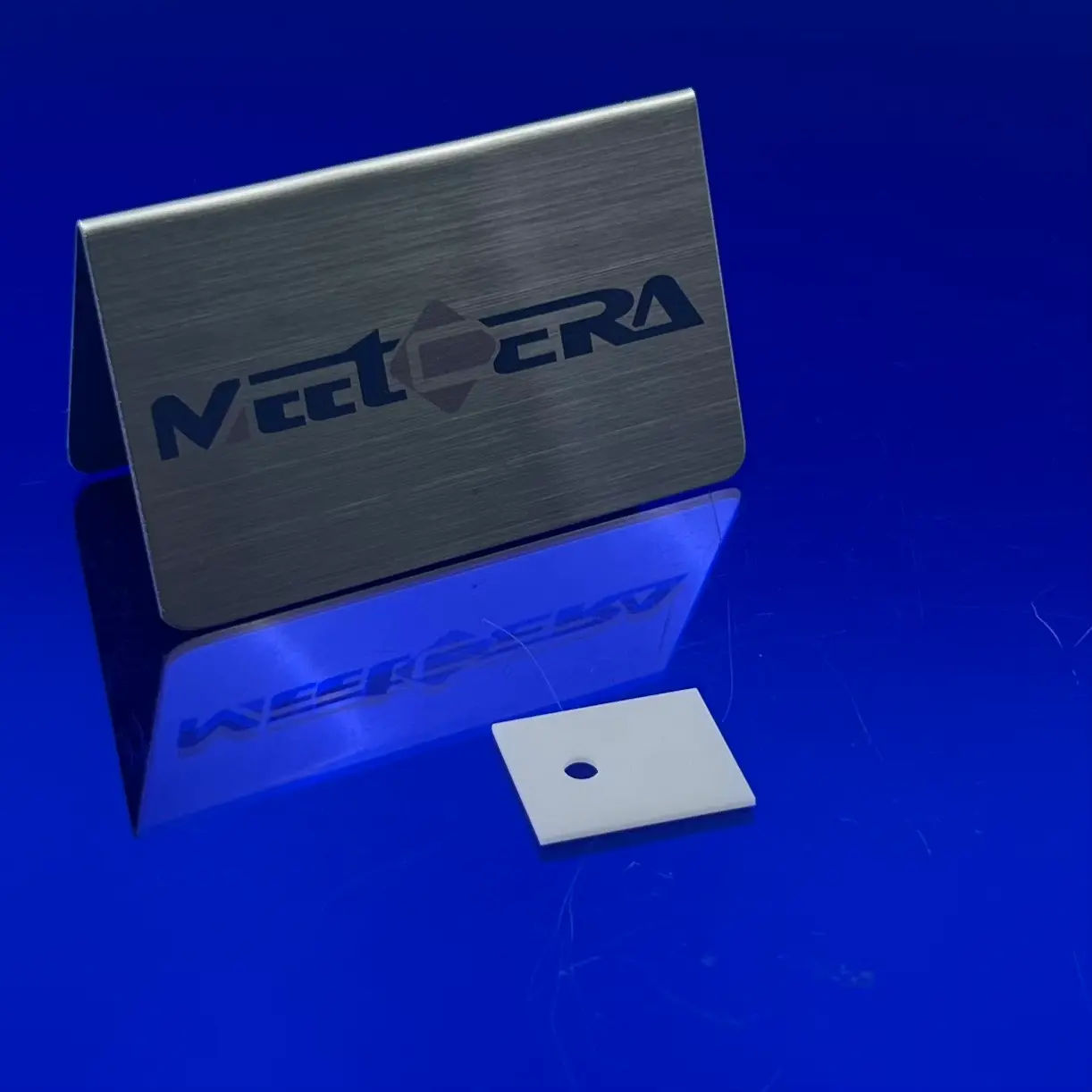

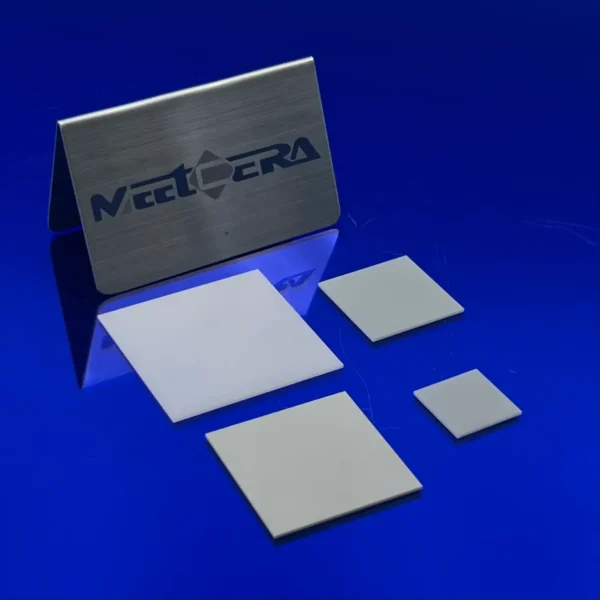

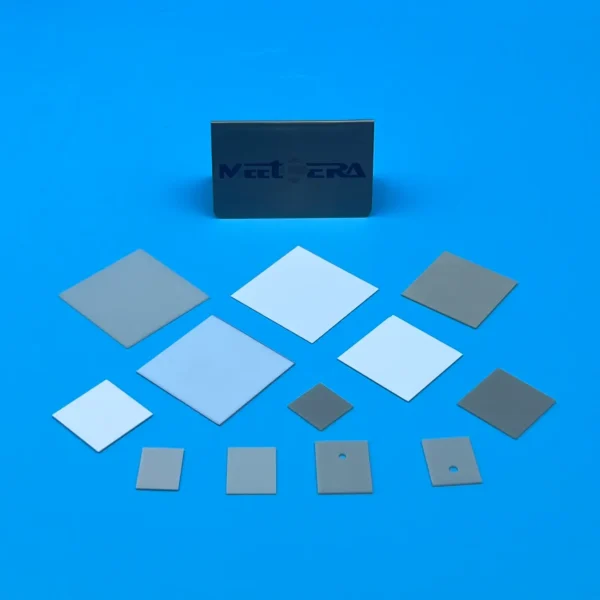

Aluminum Nitride Ceramic Substrate

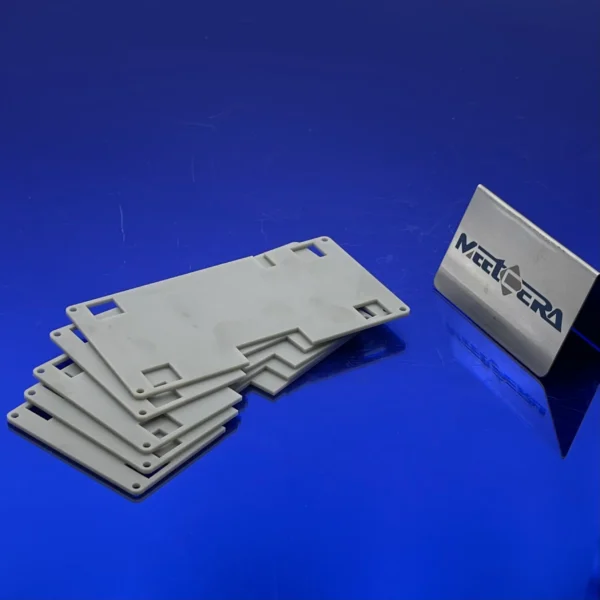

Aluminum Nitride (AlN) ceramic substrate is a high-performance advanced ceramic material renowned for its excellent thermal conductivity (≥170 W/m·K) and superior electrical insulation. It is the preferred substrate material for high-power electronics, semiconductor packaging, and advanced thermal management applications. Compared to Al₂O₃ and BeO, AlN offers significantly better heat dissipation, lower thermal stress, and greater environmental safety, while supporting precision machining and custom shapes.

Product Features:

- Extremely high thermal conductivity ≥170 W/m·K (superior to most ceramics)

- Excellent electrical insulation with high volume resistivity

- Thermal expansion coefficient highly matched to Si/GaN, minimizing thermal stress

- High mechanical strength, high temperature resistance (≥1500°C), and excellent thermal shock resistance

Related AlN Ceramic products:

- AlN ceramic substrates (standard & custom)

- AlN Direct Bonded Copper (DBC) substrates

- AlN ceramic heat sinks / heaters

- AlN crucibles & high-temperature corrosion-resistant parts

Application Scenarios:

- High-power modules & transistor substrates

- LED / semiconductor laser heat-dissipation substrates

- GaN / AlGaN epitaxial growth substrates

- High-frequency devices & power electronics packaging

FAQ

Q1: Which has better heat dissipation, AlN or Al₂O₃?

A: AlN far outperforms Al₂O₃ (170+ vs 20–30 W/m·K), making it ideal for high-power thermal management.

Q2: What is the maximum operating temperature of AlN?

A: It maintains excellent stability up to at least 1500°C; typical electronic applications use it well below this limit.

Q3: Is AlN safer than BeO?

A: Yes, AlN is non-toxic and non-radioactive, serving as the mainstream eco-friendly alternative to BeO.