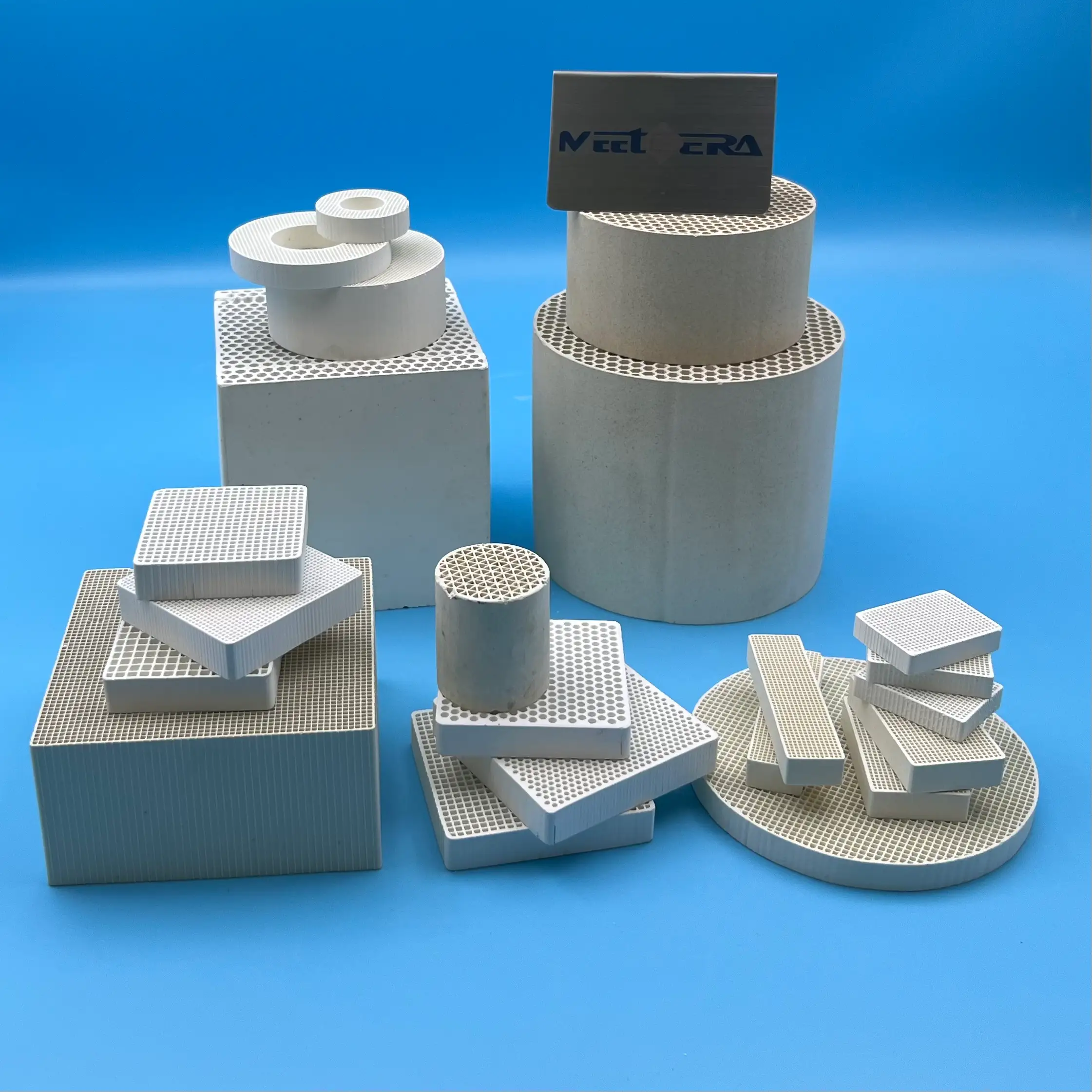

Honeycomb Ceramics

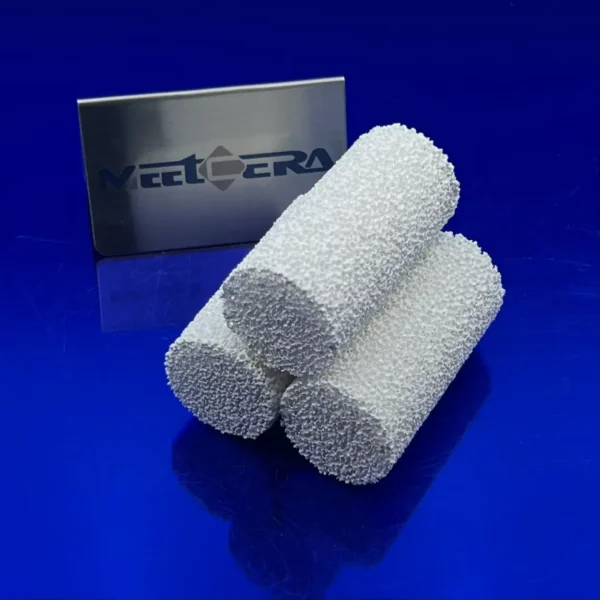

Ceramic foam filters are high-performance porous materials used for purifying molten metal during casting processes. Their open-cell three-dimensional network structure effectively removes impurities, inclusions, and oxides from molten metal, improving casting quality, reducing defects, and enhancing mechanical properties and surface finish.

Main types:

- Alumina (Al₂O₃) Ceramic Foam Filter: Suitable for aluminum and aluminum alloys, max operating temperature ~1200°C, resistant to molten aluminum corrosion.

- Silicon Carbide (SiC) Ceramic Foam Filter: Suitable for cast iron, ductile iron, gray iron, and copper alloys, max operating temperature ~1530°C, high strength and thermal shock resistance.

- Zirconia (ZrO₂) Ceramic Foam Filter: Suitable for carbon steel, stainless steel, and high-temperature alloys, max operating temperature ~1700°C, excellent thermal shock and chemical stability.

Key Features

- High filtration efficiency: Combines mechanical screening, cake filtration, and deep-bed adsorption to remove oxides, slag, and non-metallic inclusions.

- Promotes laminar flow: Reduces molten metal turbulence, minimizing porosity defects.

- Excellent thermal shock resistance, corrosion resistance, and wear resistance.

- Customizable pore sizes: 10–60 PPI to meet different filtration needs.

- Significantly improves casting quality, reduces scrap rates and processing costs.

Physical and chemical properties

|

Item

|

Unit

|

Mullite

|

loose Mullite

|

dense Mullite

|

Mullite-cordierite composite

|

Corundum

|

|

Gross Density

|

g/cm3

|

>2.9

|

2.2-2.4

|

2.7-2.9

|

>2.9

|

>3.2

|

|

Acid Resistance

|

%

|

≤0.5

|

≤0.5

|

≤0.5

|

≤0.5

|

≤0.5

|

|

(20-1000 oC)

|

10-6 oC -1

|

5.5-6.5

|

3.5-6

|

5-7

|

≤5

|

6-7

|

|

Max Working Temperature

|

oC

|

1600

|

1300

|

1360

|

1550

|

1750

|

|

Heat Capacity

|

(J/ Kg.K)

|

1100-1300

|

800-1000

|

850-1050

|

1100-1300

|

1300-1400

|

|

Heat Conductivity

|

W/MK

|

1.4-2.0

|

1.5-2.5

|

1.8-2.8

|

1.3-1.8

|

5-10

|

Applications

- Molten metal purification in foundry and metallurgy industries

- Aluminum, iron, steel, and copper casting processes

- Defect control in automotive, aerospace, and industrial components

Frequently Asked Questions (FAQ)

1. How to choose the right filter?

Select material by metal type: Alumina for aluminum alloys, SiC for iron/copper alloys, Zirconia for steel/high alloys. Choose PPI based on required fineness: 10-20 for coarse, 30-40 for standard, 50-60 for fine filtration.

2. Installation tips?

Preheat to prevent cracking, seal properly in the gating system, ensure sufficient metal head for priming, and place near the mold for best laminar flow.

For custom sizes, specifications, or quotes, please contact us.