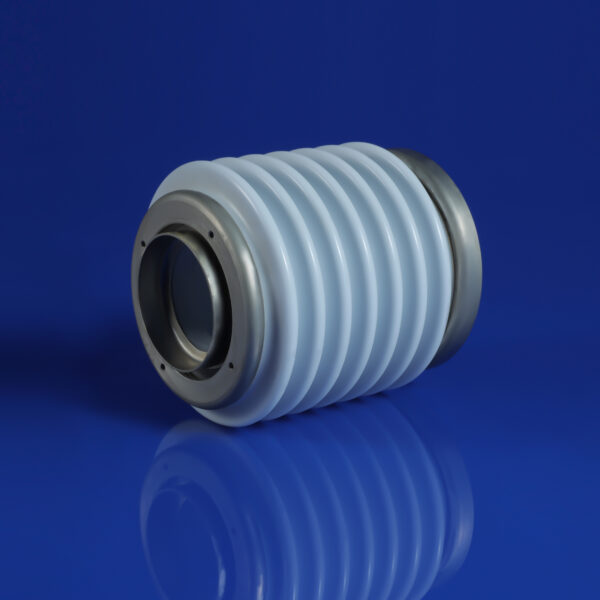

Ceramic-to-metal sealing

Metallized ceramic sealing (Metallized Ceramic / Ceramic-to-Metal Hermetic Seal) involves depositing a strong, adherent metal layer (typically molybdenum-manganese followed by nickel plating) on the surface of high-performance ceramics (such as alumina Al₂O₃ or aluminum nitride AlN) using advanced metallization processes (e.g., Mo-Mn method). This metallized ceramic is then reliably joined to metals (Kovar, NiFe alloys, stainless steel, copper alloys, etc.) through active brazing or vacuum brazing, creating high-reliability, vacuum-tight ceramic-to-metal composite assemblies.

Key Performance Advantages:

- Exceptional hermeticity: Helium leak rate ≤ 1×10⁻⁹ atm·cc/sec (some reaching 1×10⁻¹⁰ to 1×10⁻¹² Pa·m³/s)

- Superior insulation: Insulation resistance > 1 GΩ @ 100 VDC, withstand voltage > 10,000 psi

- Wide temperature range: Operating from -269°C to +800°C+ (depending on material combination)

- Outstanding mechanical & environmental resistance: High strength, abrasion resistance, corrosion resistance, thermal shock resistance, low dielectric loss

- Reliable bond strength: Tensile/shear strength ≥ 120–800 MPa

Typical Application Fields:

- Aerospace: High-voltage/high-temperature feedthroughs, vacuum electronic devices

- Medical: Implantable devices, X-ray tubes, precision probes

- Vacuum/Semiconductor: Mass spectrometers, RF/microwave components, laser systems

- Energy/Industrial: Gas detectors, oil & gas equipment, high-power electronic packaging

- Others: Particle accelerators, deep-sea sensors, extreme-environment instrumentation

Frequently Asked Questions

1.What is the maximum operating temperature?

Depending on material combination, typical operating temperatures reach 500–800°C or higher; special configurations support even greater temperatures.

2.What is the hermeticity standard?

Standard helium leak rate ≤ 1×10⁻⁹ atm·cc/sec; high-end products can achieve 1×10⁻¹⁰ to 1×10⁻¹² Pa·m³/s.

3.Do you offer customization and what are the lead times?

Yes, full customization is supported from single-pin to complex multi-pin designs. Prototype lead time is typically 4–8 weeks; production lead time varies by quantity.

Manufactured with advanced processes (precision cleaning → metallization sintering → nickel plating → assembly & brazing → helium leak & electrical testing), ensuring batch consistency and long-term reliability. Full customization is supported, from single-pin feedthroughs to complex multi-pin assemblies.

We deliver high-quality metallized ceramic hermetic sealing solutions to empower your projects in extreme environments and high-reliability applications!