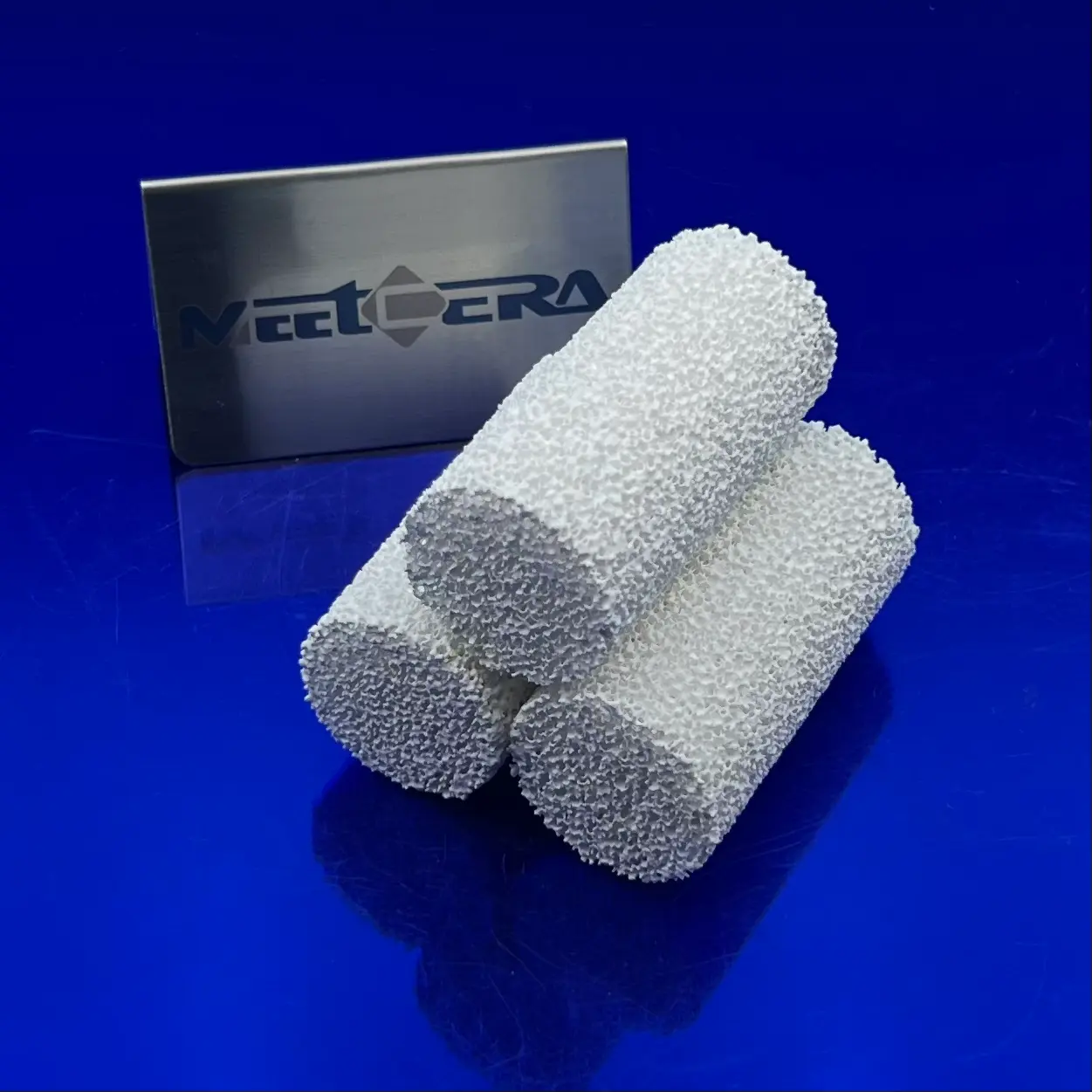

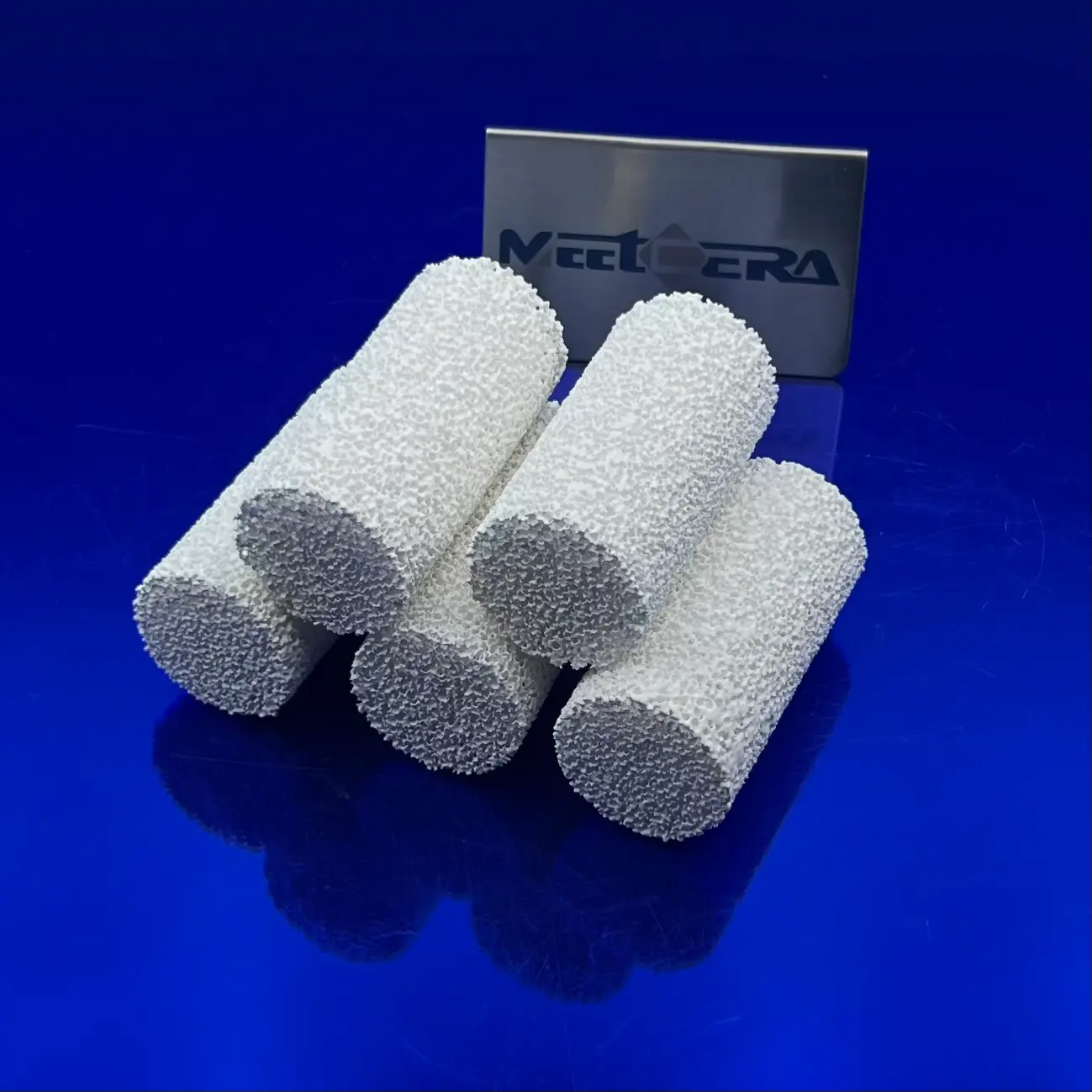

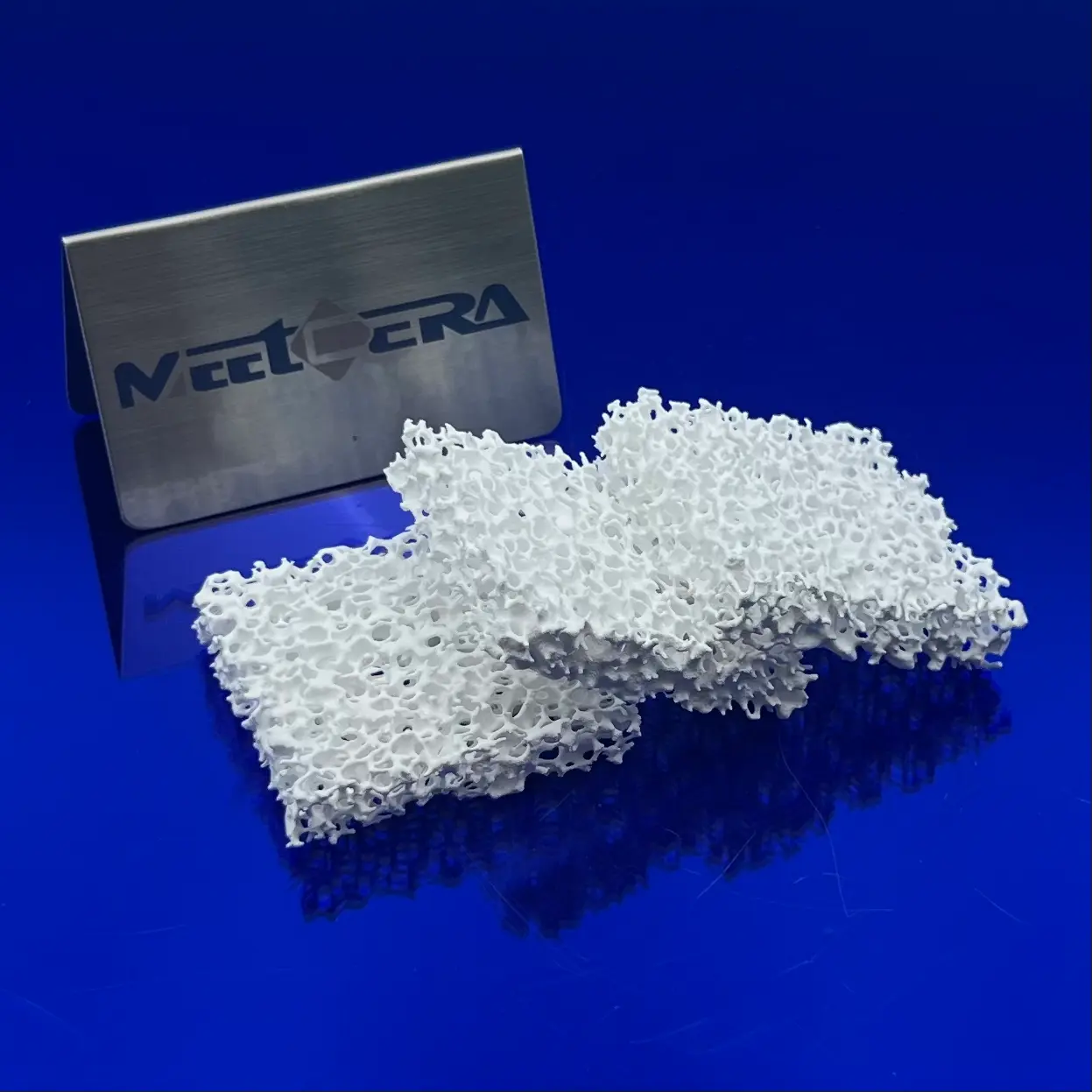

Porous Ceramic Foam Filter

Porous ceramic foam filters (CFF) feature a three-dimensional open-cell structure for efficient molten metal filtration in foundries. They effectively remove inclusions, oxide slag, and entrapped gases from aluminum, cast iron, steel, and other alloys, while promoting laminar flow. This improves metal cleanliness, casting quality, reduces defects and rejects, and boosts profitability.

Product Features

- Superior Filtration Efficiency — Three-dimensional reticulated structure with large internal surface area, low flow resistance, and excellent removal of inclusions & slag

- Outstanding Thermal Shock Resistance — Withstands ≥6 rapid cycles from 1100°C to room temperature without cracking

- High Porosity & Corrosion Resistance — 80-90% porosity for excellent permeability; material-specific design prevents melt contamination

- No Secondary Pollution & Customizable — No shedding or contamination; fully customizable sizes, shapes, and PPI (8-60)

Parameter Table (Comparison of Three Main Materials)

| Parameter | Alumina (Al₂O₃) | Silicon Carbide (SiC) | Zirconia (ZrO₂) |

|---|---|---|---|

| Color | White | Gray-black | Yellow |

| Pore Density (PPI) | 8-60 | 8-60 | 8-60 |

| Porosity | 80-90% | 80-90% | 80-90% |

| Working Temperature | ≤1200°C | ≤1500°C | ≤1700°C |

| Bending Strength | >0.6 MPa | >0.8 MPa | >1.0 MPa |

| Compressive Strength | >0.8 MPa | >0.9 MPa | >1.2 MPa |

| Bulk Density | 0.3-0.45 g/cm³ | 0.35-0.5 g/cm³ | 0.9-1.5 g/cm³ |

| Thermal Shock Resistance | 1100°C – Room Temp ≥6 cycles | 1100°C – Room Temp ≥6 cycles | 1100°C – Room Temp ≥6 cycles |

| Typical Applications | Aluminum, aluminum alloys & other non-ferrous alloys | Ductile iron, malleable iron, gray iron & other cast irons | High-melting alloys (e.g., steel, alloy steel, stainless steel) |

Application Scenarios

- Alumina Type: Primarily for aluminum and aluminum alloy casting (e.g., automotive wheels, engine blocks, phone cases, aerospace profiles). Effectively removes oxide inclusions, improves surface quality and mechanical properties.

- Silicon Carbide Type: Suitable for cast iron (gray, ductile, compacted graphite), copper alloys, and other non-ferrous metals. High temperature resistance and erosion resistance make it ideal for high-flow pouring.

- Zirconia Type: Designed for stainless steel, alloy steel, high-temperature alloys, etc. Exceptional corrosion resistance for precision steel castings and aerospace components.

- Other Uses: High-temperature gas filtration, chemical packing, catalyst supports, etc.

Frequently Asked Questions (FAQ)

Q 1: Does the ceramic foam filter need preheating?

A: Yes, preheating is recommended. Alumina type: 150–300°C; SiC/Zirconia type: 300–400°C, hold for 10–15 minutes. This prevents cracking and improves filtration performance.

Q 2: How to choose PPI (pore density)?

A: 8–15 PPI for coarse filtration (high flow, large inclusions); 20–30 PPI most common (balanced precision & flow, recommended for general castings); 40–60 PPI for fine filtration (high cleanliness needs, e.g., aerospace aluminum). Start with 20–30 PPI for testing.

Q 3: Can it be reused?

A: Not recommended. Retained slag and filter cake cause secondary contamination or blockage. Typically single-use and discarded as general industrial waste