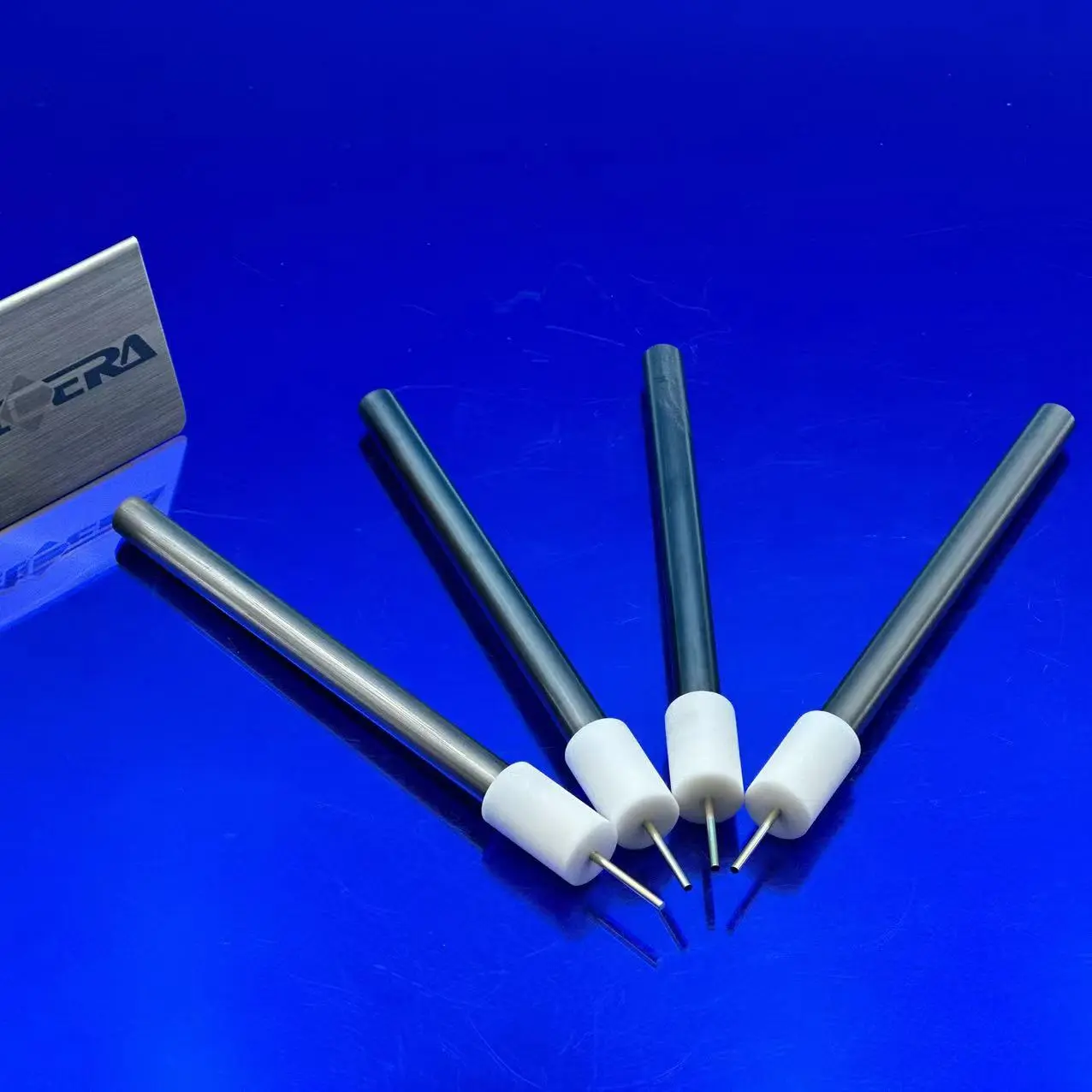

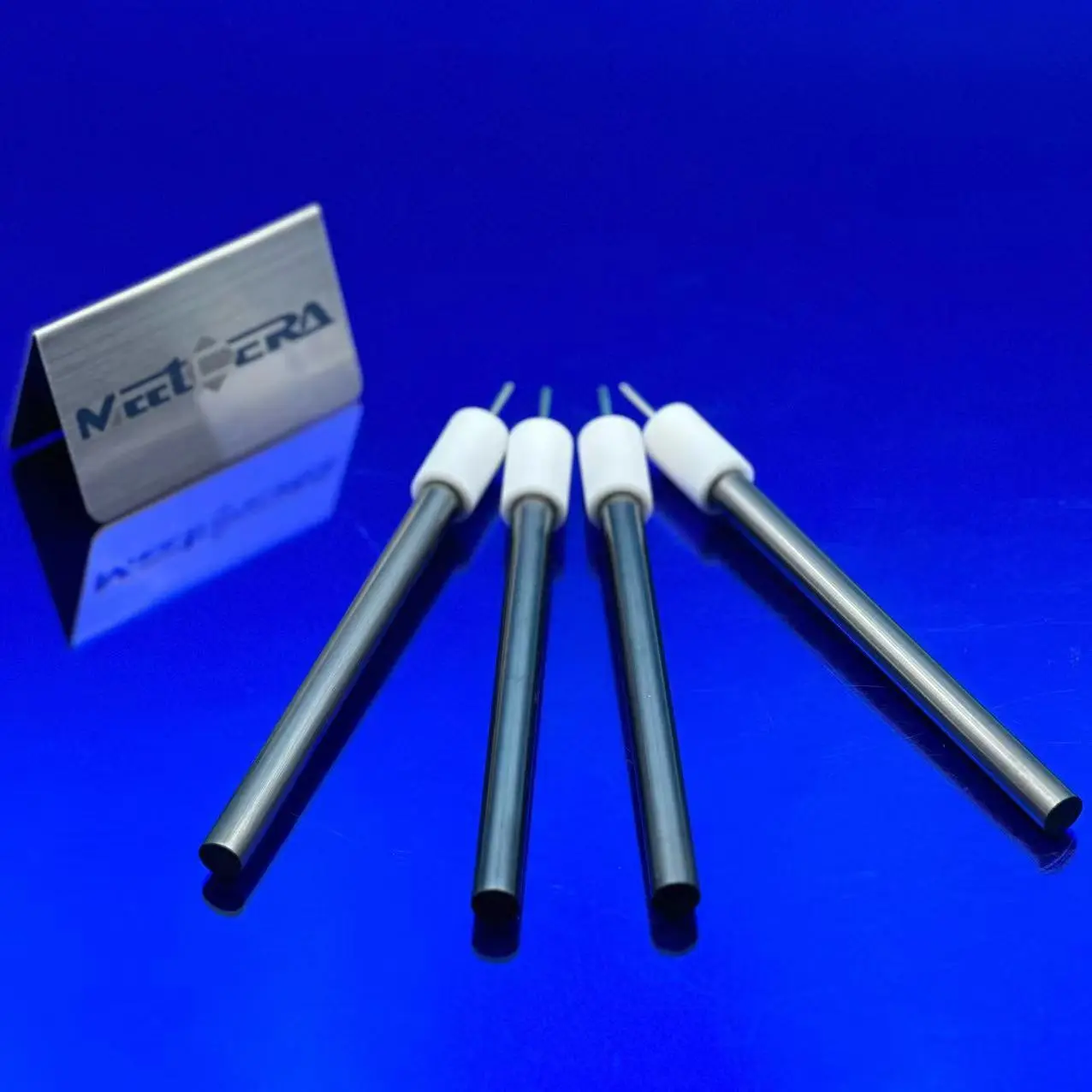

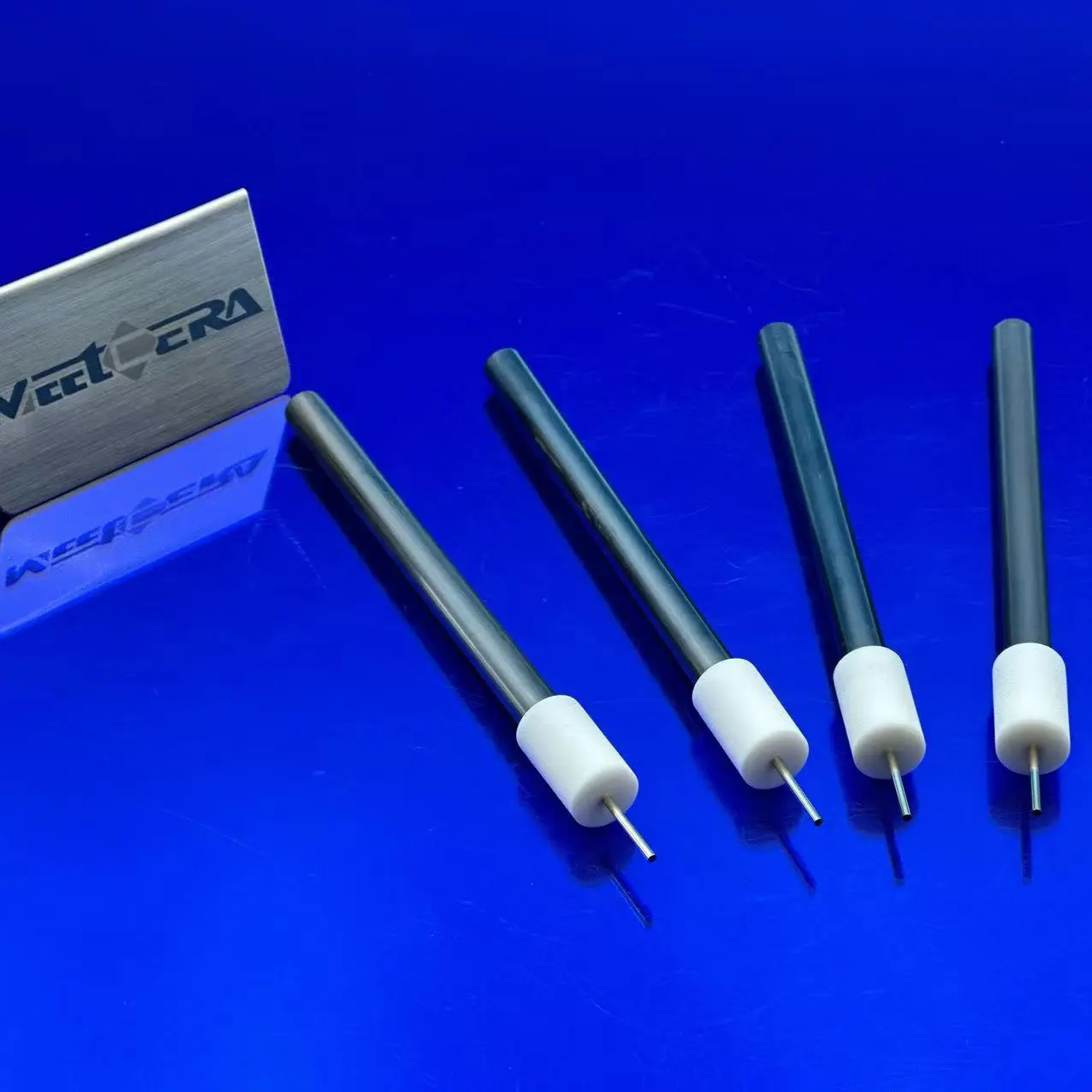

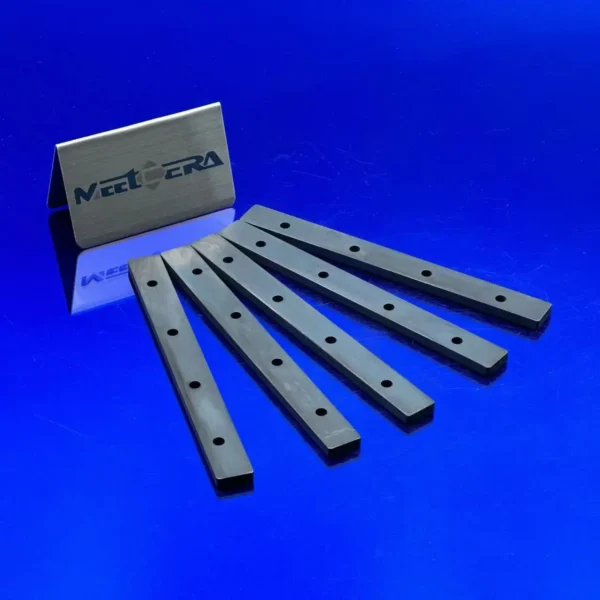

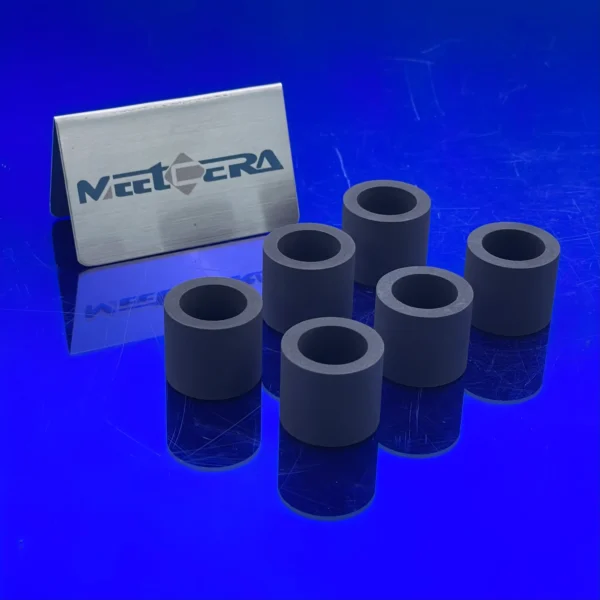

High-Purity Graphite Electrode Rod

This high-purity graphite electrode rod is crafted from premium fine-grain isostatic graphite and precision-machined. It offers exceptional purity (≥99.9%), outstanding electrical conductivity, and excellent high-temperature performance. Ideal for electrochemical experiments, arc discharge, laboratory electric furnaces, battery testing, semiconductor auxiliary components, and more. A reliable conductive material for research, electronics, metallurgical analysis, and new energy experiments.

Product Features:

- Excellent Electrical Conductivity: Low resistivity, strong current-carrying capacity, uniform and stable conduction

- Ultra-High Temperature Resistance: Up to 3000°C in vacuum/inert atmospheres; stable above 1000°C in air

- High Purity & Low Impurities: Extremely low ash content, effectively prevents sample contamination and ensures experimental accuracy

Product Specifications:

| Parameter | Unit | Typical Value | Remark |

|---|---|---|---|

| Material Purity | — | ≥99.9% | High-purity fine-grain graphite |

| Bulk Density | g/cm³ | 1.75–1.85 | Isostatic pressing |

| Resistivity | μΩ·m | 10–16 | At room temperature |

| Flexural Strength | MPa | ≥40–60 | — |

| Maximum Operating Temperature | °C | 3000 (vacuum/inert) ≈1000 (air) | Depends on atmosphere |

| Thermal Expansion Coefficient | 10⁻⁶/°C | 3.0–5.0 | Room temp to 1000°C |

| Ash Content | ppm | ≤200 | Ultra-low ash grades available |

| Common Diameter Range | mm | 3–50 | Custom sizes supported |

| Common Length Range | mm | 50–1000 | Can be cut or threaded |

Application Scenarios

- Laboratory electrochemical experiments, electrolysis, electroplating, arc discharge

- Battery material testing and fuel cell electrode research

- Heating elements or auxiliary electrodes in high-temperature / vacuum furnaces

FAQ

Q1: Can the graphite electrode rod be used for long-term high-temperature operation in air?

A: In air, it is recommended to limit the temperature to 800–1000°C to minimize oxidation loss. For higher temperatures, use vacuum or inert gas (nitrogen/argon) to significantly extend service life.

Q2: How to select the appropriate diameter and length?

A: Choose based on current load and equipment clamping size—larger diameters handle higher currents. Common lab sizes are 5–20 mm in diameter. Length depends on the reaction vessel/setup. Feel free to consult our team for recommendations.

Q3: How to clean and store the electrode after use?

A: Allow to cool, then gently brush off surface residues. Avoid impact. For oxidized layers, lightly polish with fine sandpaper. Store in a dry, moisture-free environment and protect from sudden temperature changes or mechanical damage.

Need custom specifications (ultra-fine/ultra-thick diameter, special lengths, threading, high-purity coating, etc.) or want the latest pricing, stock availability, or free sample testing? Welcome to contact our professional technical team anytime! We provide one-stop high-temperature graphite solutions and look forward to partnering with you to create greater value!