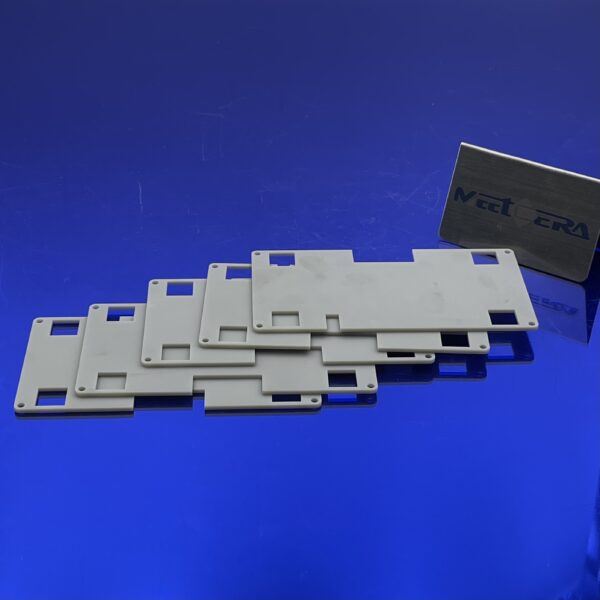

High hardness anti-corrosion for industrial alumina ceramic plates/parts

Alumina, also known as Aluminum Oxide, is a hard wearing advanced technical ceramic

material frequently used in a wide variety of industrial applications. Once fired and sintered,

it can only be machined using diamond-grinding methods.

It features high hardness and wear resistance, low erosion levels, high temperature resistance,

corrosion resistance, and bioinertness .Additionally, it can be highly polished, making it useful

for a wide range of applications.

Properties:

1. Good electrical insulation

2. Moderate thermal conductivity

3. High corrosion and wear resistance

4. Good gliding properties

5. High mechanical strength

6. High compressive strength

7. High hardness

1. Good electrical insulation

2. Moderate thermal conductivity

3. High corrosion and wear resistance

4. Good gliding properties

5. High mechanical strength

6. High compressive strength

7. High hardness

Alumina ceramics features:

1).Excellent electrical insulation

2).High hardness

3).Relatively low strength and fracture toughness

4).Resistance to wear and corrosive

5).Excellent thermal stability

6).Resistance to high temperatures

7).High electrical resistivity

8).Good chemical stability and resistance

9).High corrosion resistance

10).Excellent thermal shock resistance

11).High thermal insulation

12).A Low Young’s modulus

1).Excellent electrical insulation

2).High hardness

3).Relatively low strength and fracture toughness

4).Resistance to wear and corrosive

5).Excellent thermal stability

6).Resistance to high temperatures

7).High electrical resistivity

8).Good chemical stability and resistance

9).High corrosion resistance

10).Excellent thermal shock resistance

11).High thermal insulation

12).A Low Young’s modulus

|

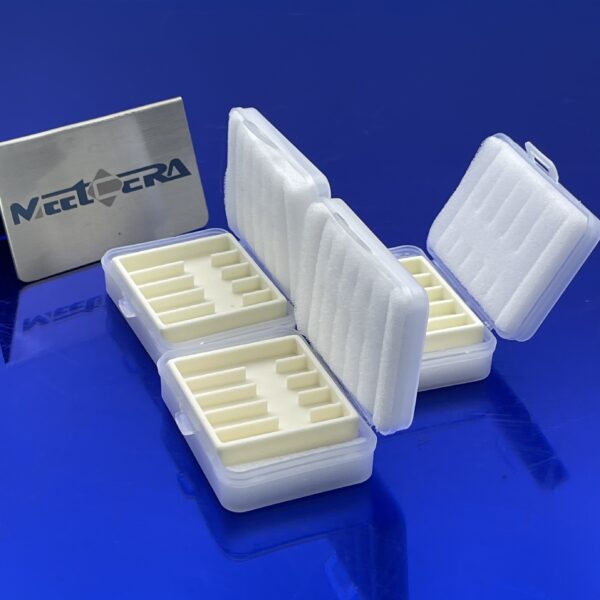

Product Name

|

Precision Ceramic Metallization Housings for Relays

|

|

Compositions

|

96.0% alumina or 99.5% high purity alumina (Al2O3)

|

|

Metalization

|

Sintered with Molybdenum & Manganese (Mo+Mn), then Nickel plating

|

|

Mo+Mn Layer

|

25 +/-10μm in thickness

|

|

Nickel Layer

|

2 -10μm in thickness

|

|

Helium Leak Testing

|

1×10-12 Pa·m3/s

|

|

Tensile Strength

|

≥800Kg/cm2

|

|

Material Density

|

3.68 – 3.90 g/cm3

|

|

Tolerance

|

+/- 0.005mm

|

|

Finishing

|

Ra 0.02

|

|

Max. Using Temperature

|

1650 oC

|

|

Using Fields

|

DC Relayer, Fuel Cell Units, New Energy Vehicles, Charging Piles, DC Railway, Electric Forklifts, Electrical Appliance, Electric

Products |