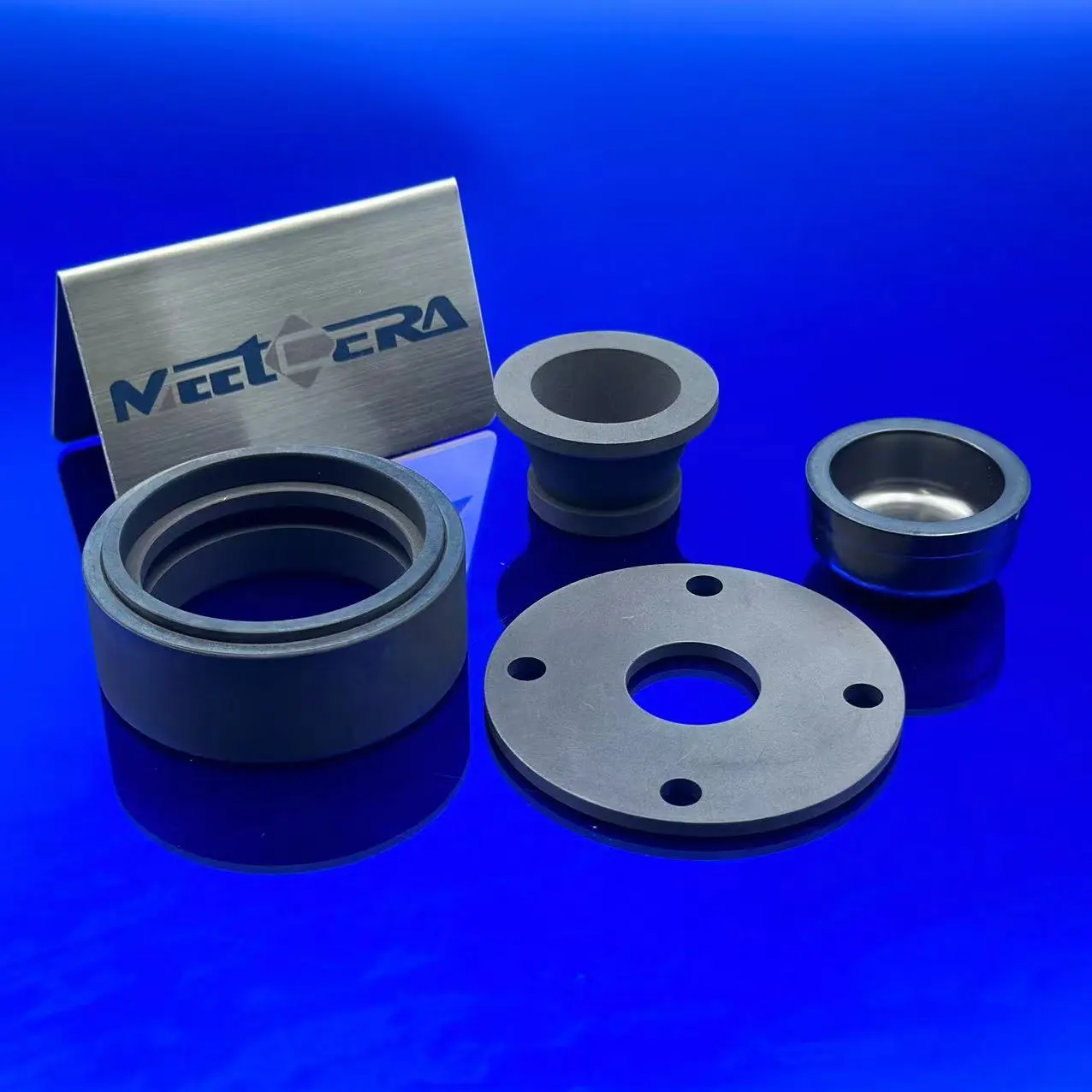

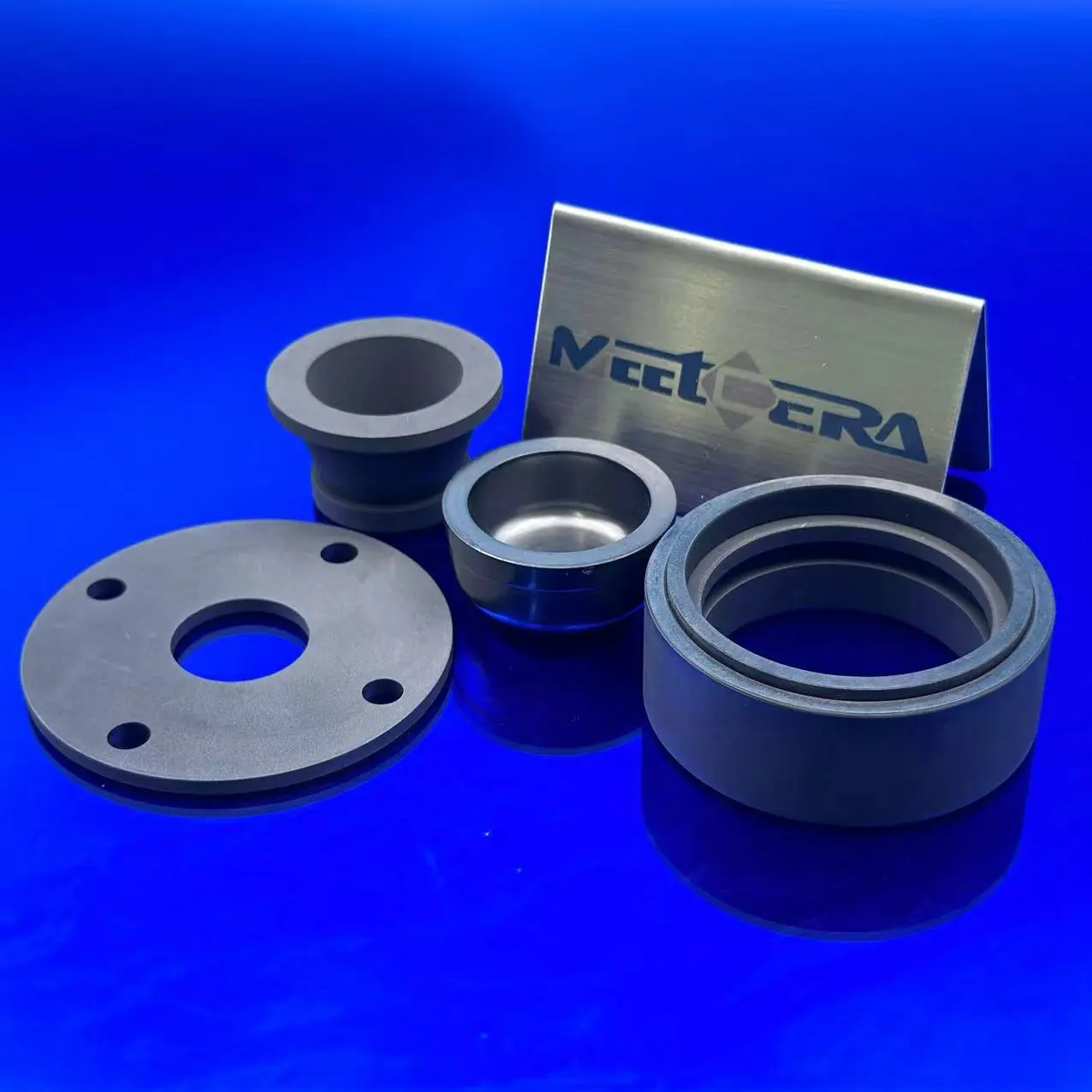

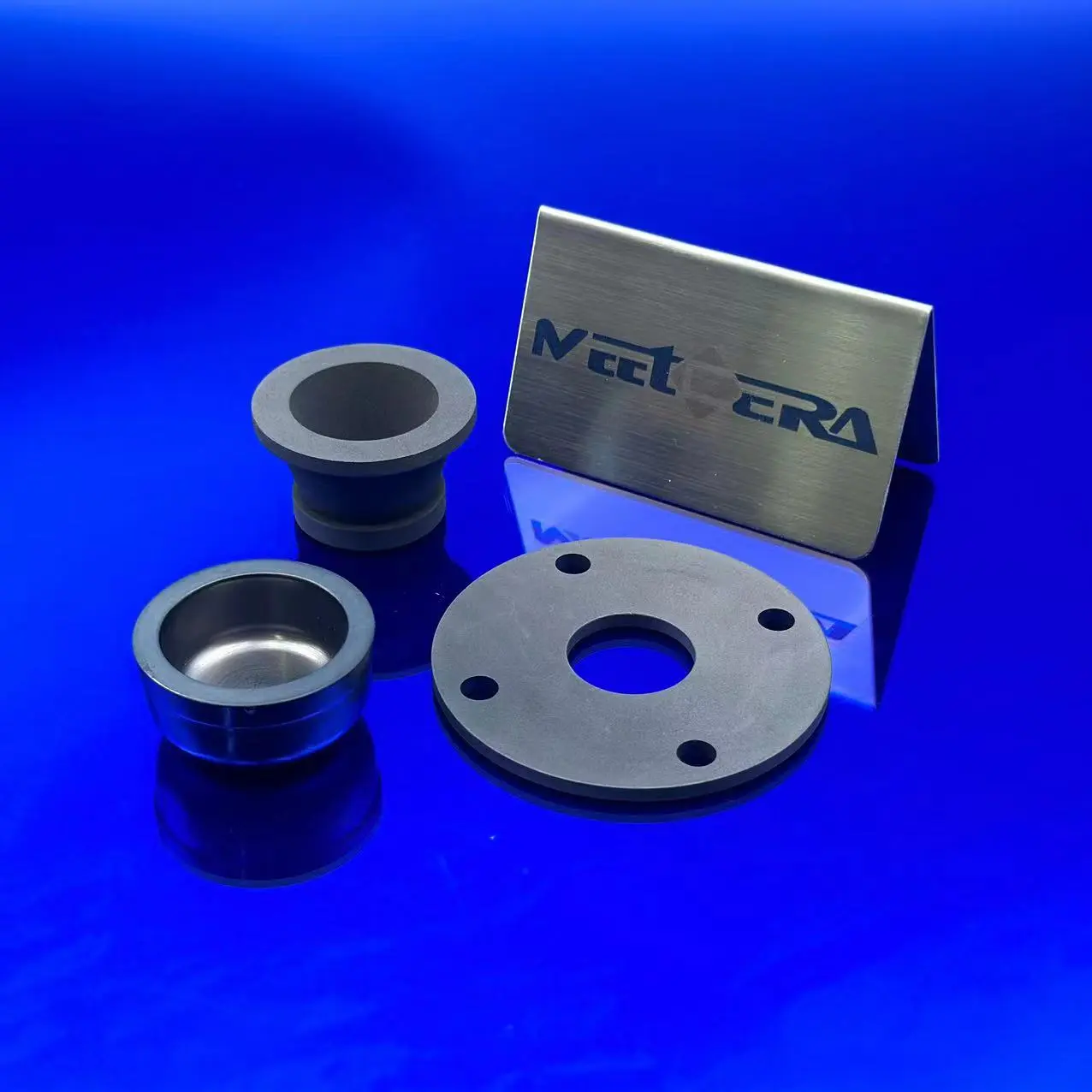

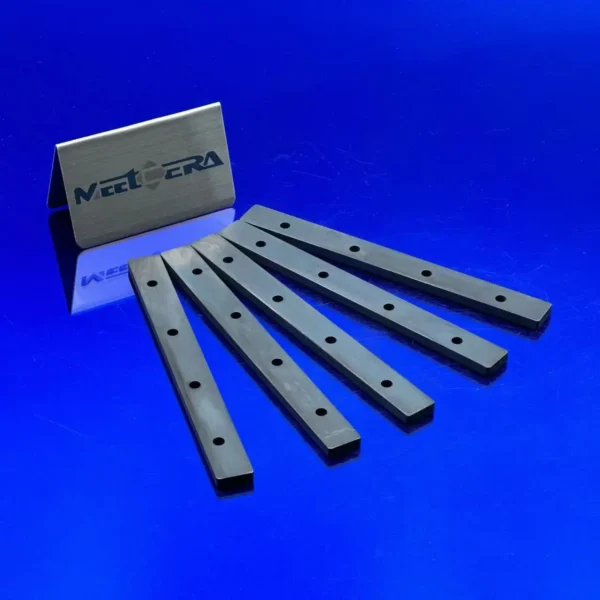

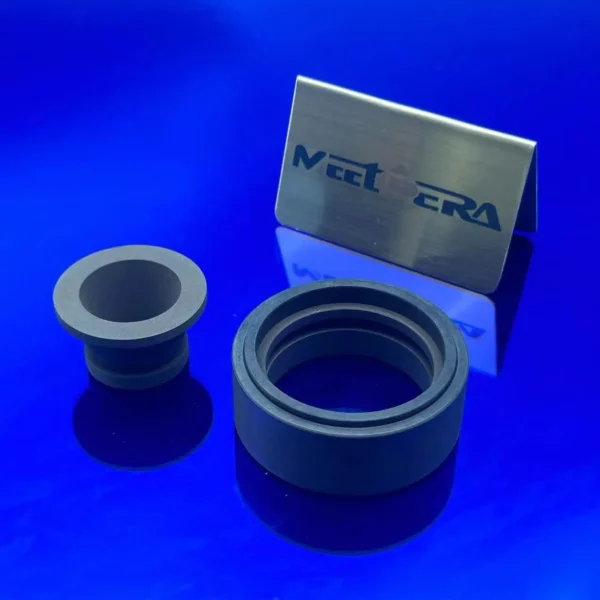

High-Performance Graphite Accessories

High-purity graphite products made from premium flake or isostatic graphite, with carbon content ≥99.9% (up to 99.999%). Features ultra-low ash, excellent heat resistance (up to 3000°C in inert/vacuum), superior conductivity, and strong chemical stability. Ideal for metallurgy, semiconductors, new energy batteries, photovoltaics, lab research, and vacuum furnaces.

Product Features:

- Ultra-High Purity: Ash ≤200 ppm (customizable to ≤50 ppm or lower), prevents sample/melt contamination

- Exceptional High-Temperature Resistance: Up to 2800–3000°C in vacuum/inert; stable at 1000–1800°C in air

- Excellent Electrical & Thermal Conductivity: Low resistivity, high thermal conductivity, uniform heating, energy-efficient

Product Specification:

| Form | Common Specification Range | Typical Application Scenarios | Remark |

|---|---|---|---|

| Graphite Crucible | Capacity 1–5000 mL, Diameter 30–500 mm | Precious metal melting, semiconductor synthesis | Anti-oxidation coating available |

| Graphite Electrode Rod | Diameter 3–50 mm, Length 50–1000 mm | Electrochemical experiments, arc discharge, battery testing | Threaded or ultra-fine grain optional |

| Graphite Plate/Sheet | Thickness 1–100 mm, Custom sizes | Vacuum furnace insulation, heating elements, sealing gaskets | High-strength / isotropic grades available |

| Graphite Mold / Heater | Custom dimensions | Crystal growth, powder metallurgy, hot pressing | SiC coating or special treatments supported |

Application Scenarios:

- Precious metal / rare metal melting and refining

- Semiconductor / photovoltaic silicon material thermal field components

- High-temperature calcination of new energy battery cathode and anode materials

FAQ

Q1: Can graphite products be used long-term in air at high temperatures?

A: Recommended max 1000–1800°C in air (depending on grade/coating). Use vacuum or inert gas for higher temperatures to avoid oxidation.

Q2: How to choose the right specifications?

A: Match to temperature, atmosphere, size/load, and purity needs. Share your application — we’ll recommend the best option for free.

Q3: How to clean and store after use?

A: Cool, brush off residues gently, avoid impact. Lightly polish oxidized areas if needed. Store dry and protected from sudden temperature changes.

Need custom specifications (ultra-high purity, special dimensions, enhanced coatings, bulk production, etc.) or want the latest pricing, stock availability, or free sample testing? Welcome to contact our professional technical team anytime! We provide one-stop high-temperature graphite solutions and look forward to partnering with you to create greater value!