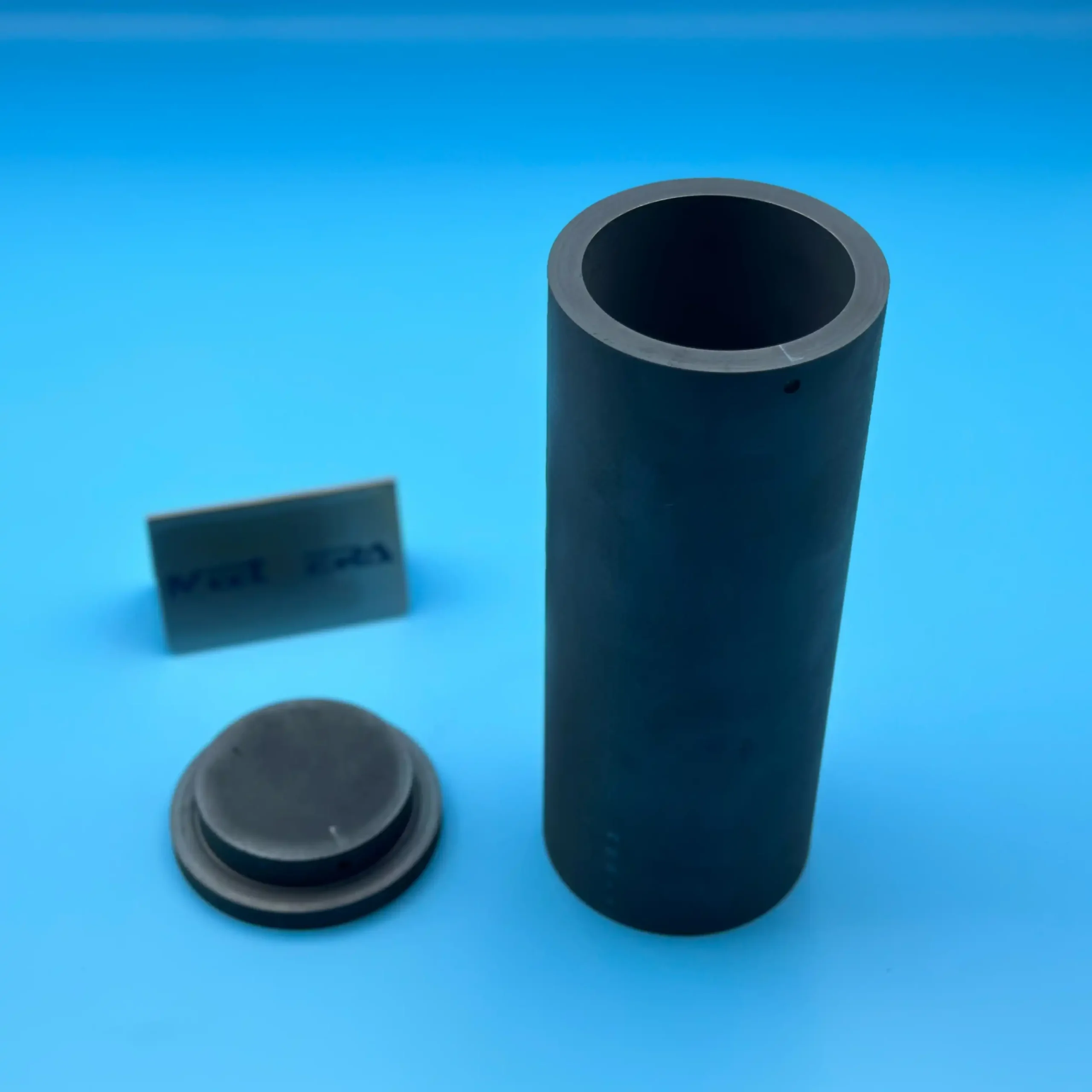

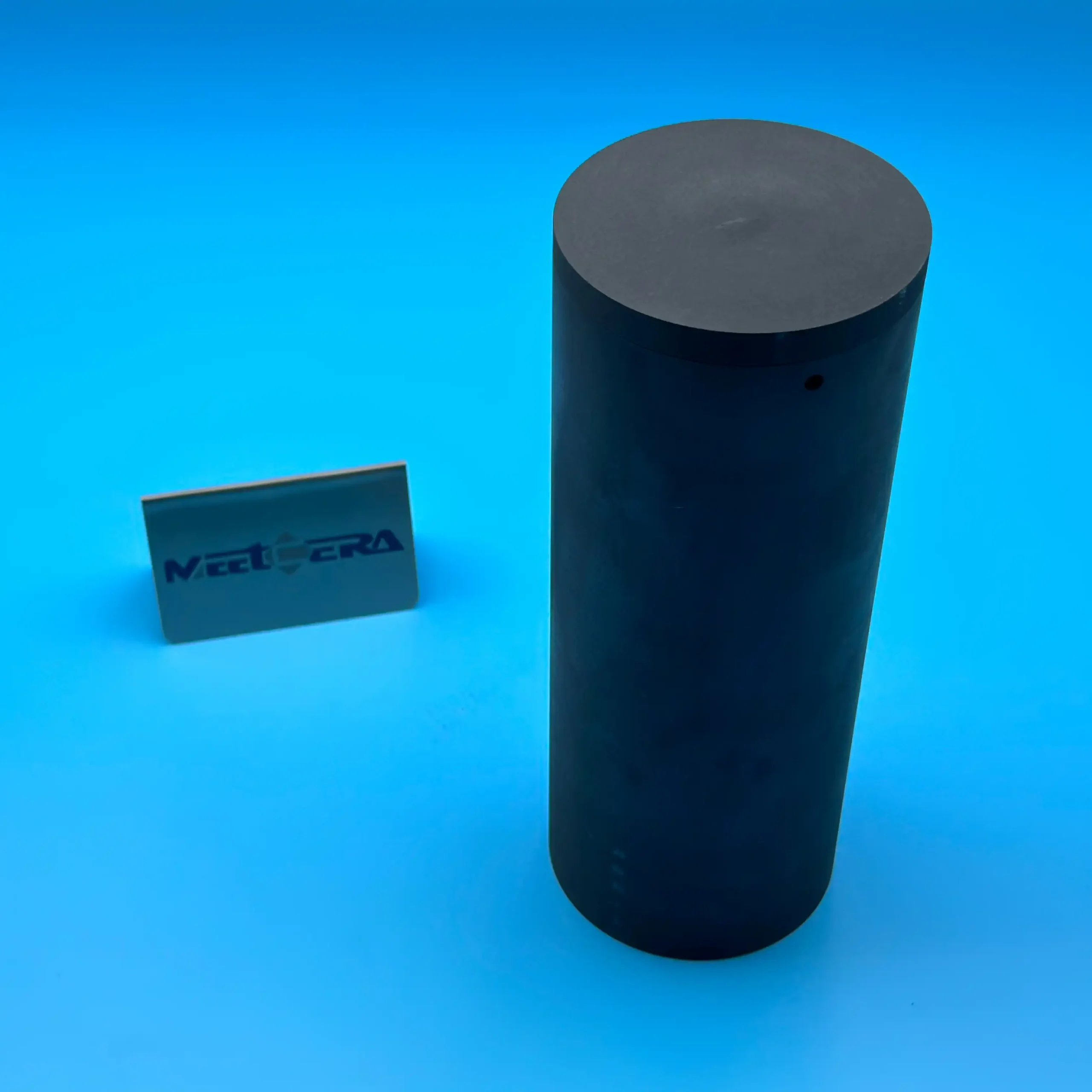

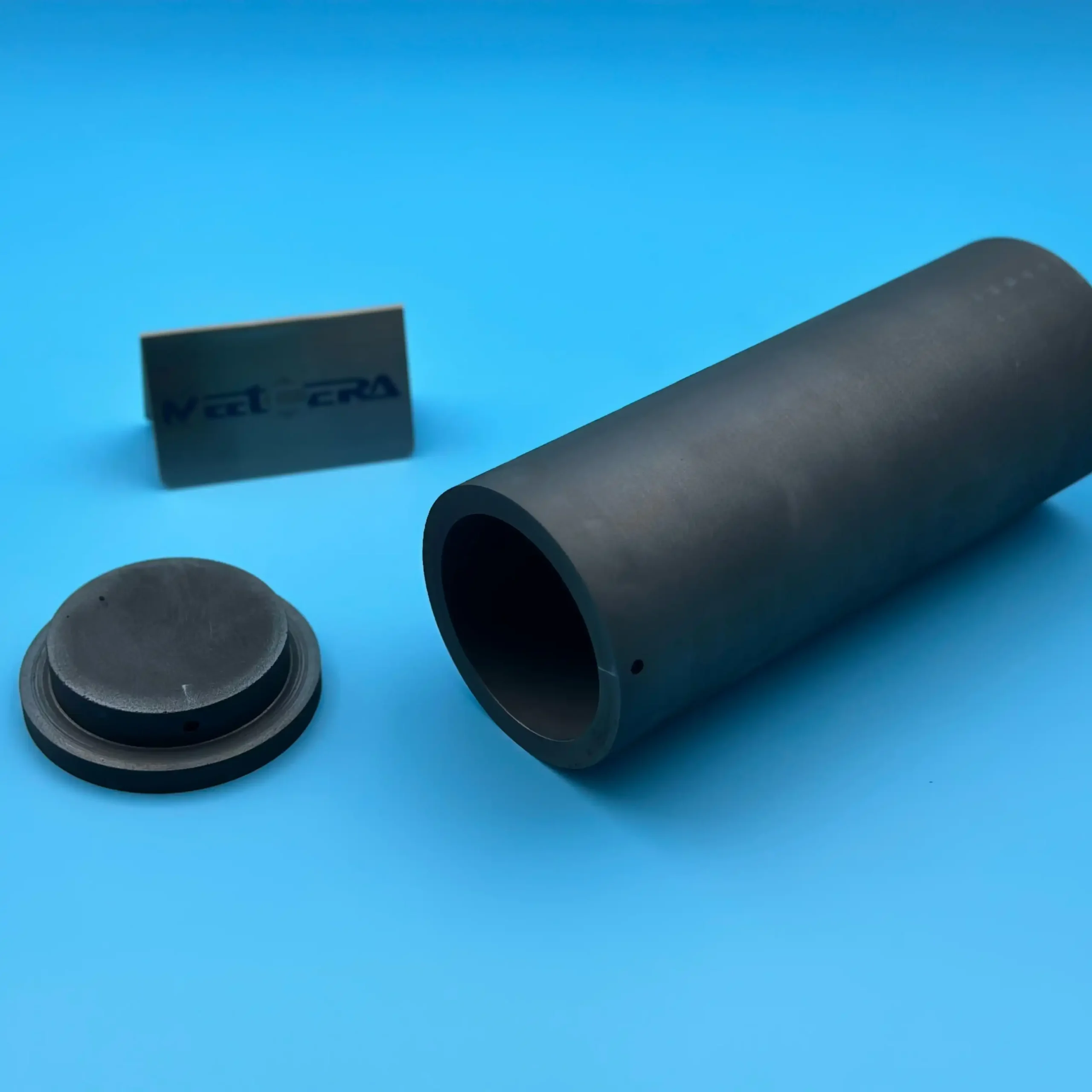

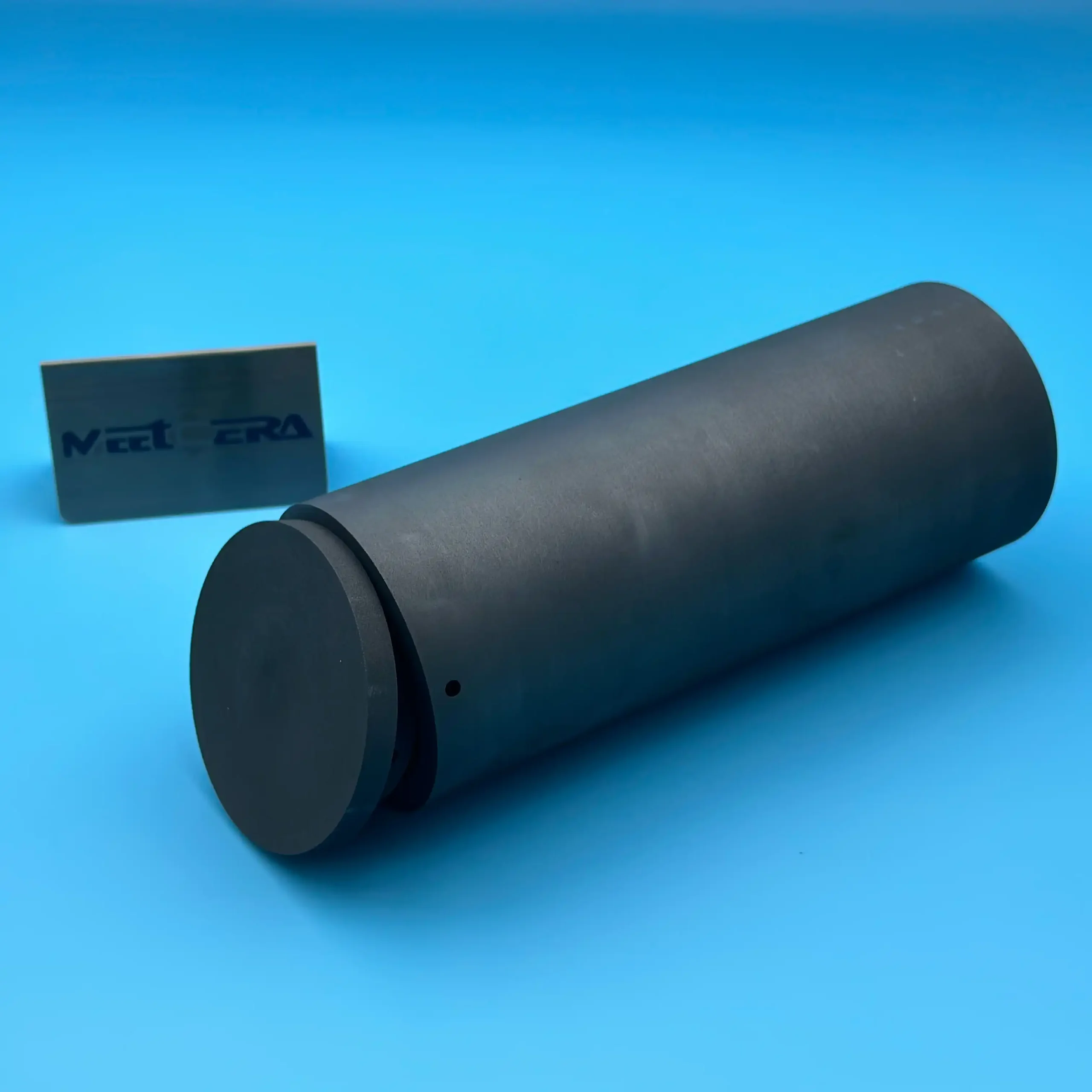

High-Purity Graphite Crucible

This high-purity graphite crucible is made from premium natural flake graphite and precision-formed using isostatic pressing technology. It features exceptional purity (≥99.9%), outstanding high-temperature resistance, and excellent thermal shock resistance. Maximum operating temperature reaches 2800°C in inert or vacuum atmospheres. Widely used in precious metal melting, laboratory high-temperature experiments, and new energy material preparation.

Product Features

- Ultra-High Temperature Resistance: Up to 2800–3000°C in inert/vacuum conditions; stable up to 1600–1800°C in air

- Excellent Thermal Shock Resistance: Withstands rapid heating and cooling without cracking, longer service life

- High Purity & Low Contamination: Extremely low ash content, effectively prevents secondary sample contamination

Product Specifications

| Parameter | Unit | Typical Value | Remark |

|---|---|---|---|

| Material Purity | — | ≥99.9% | High-purity natural flake graphite |

| Bulk Density | g/cm³ | 1.75–1.90 | Isostatic pressing |

| Maximum Operating Temperature | °C | 2800 (inert/vacuum) 1600–1800 (air) | Depends on atmosphere |

| Thermal Conductivity | W/(m·K) | 100–150 | At room temperature |

| Common Capacity Range | mL | 1–5000 | Custom sizes available |

Application Scenarios

- Precious metal melting and refining (gold, silver, platinum, etc.)

- Laboratory high-temperature calcination and sintering experiments

- High-temperature processing of new energy battery materials and semiconductor materials

FAQ

Q1: Can the graphite crucible be used in air?

A: Yes, but it is recommended to keep the temperature below 1600–1800°C in air. For higher temperatures, use inert gas or vacuum to minimize oxidation and extend service life.

Q2: How to choose the right crucible capacity?

A: It is best to fill the crucible to 70%–80% of its capacity with material. For example, 1 kg of gold/silver typically requires a 200–300 mL crucible. Feel free to consult our team for recommendations.

Q3: How to clean and maintain the crucible after use?

A: Allow it to cool, then gently brush off residues. Avoid mechanical impact. For stubborn residues, lightly clean with dilute hydrochloric acid, rinse, and dry thoroughly. Avoid sudden temperature changes.

Need custom specifications (extra large/small, special wall thickness, anti-oxidation coating, etc.) or want the latest pricing, stock availability, or free sample testing? Welcome to contact our professional technical team anytime! We provide one-stop high-temperature graphite solutions and look forward to partnering with you to create greater value!