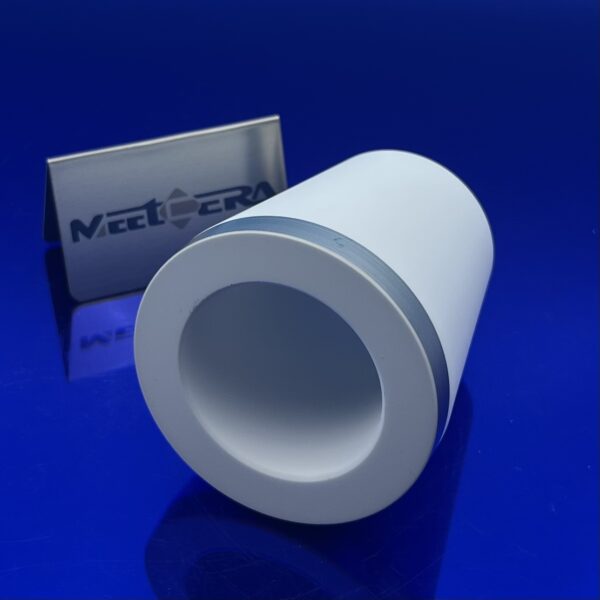

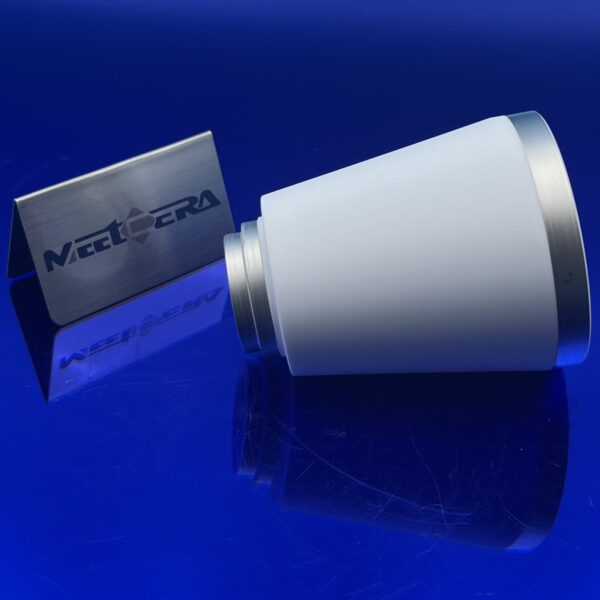

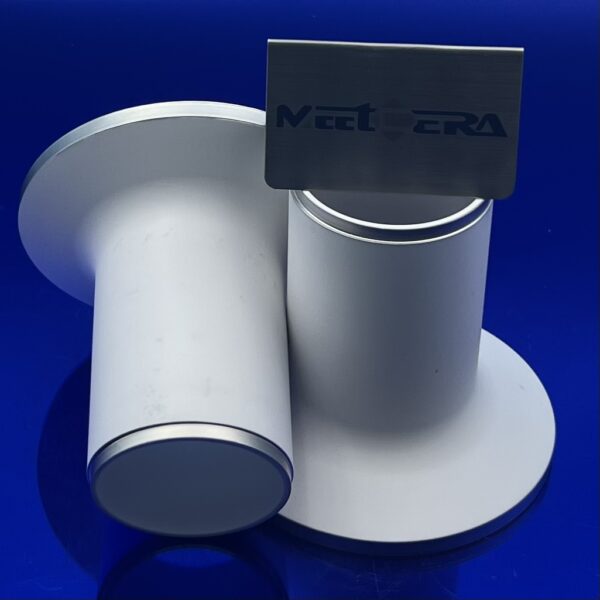

alumina ceramics and metal materials

In practical applications, the sealing process of alumina ceramics and metal materials has become more and more popular. In order

to achieve perfect ceramic-metal sealing, the most important step is to do a good job of metallization of alumina ceramics which

will affect the final sealing effect. The methods of ceramic metallization mainly include:

– electroless Ni-P plating method

– electroplating Ni-P alloy method

– high temperature sintering by Ag(Ni) method

– Mo-Mn sintering method

– vacuum evaporation coating method

– vacuum sputtering coating method

to achieve perfect ceramic-metal sealing, the most important step is to do a good job of metallization of alumina ceramics which

will affect the final sealing effect. The methods of ceramic metallization mainly include:

– electroless Ni-P plating method

– electroplating Ni-P alloy method

– high temperature sintering by Ag(Ni) method

– Mo-Mn sintering method

– vacuum evaporation coating method

– vacuum sputtering coating method

|

Material

|

Alumina/BeO/AlN

|

|

Coating Layer

|

Mo/MnThickness:8-30μm

|

|

Plated Layer

|

Nickel, Copper, Gold, etc. Thickness: 2-9μm

|

|

Treatment

|

Glazed, polishing

|

|

Dimension

|

Customized

|

|

Joining types

|

|

|

Ceramic + Mo/Mn Metallized + plating Ni

|

|

|

Ceramic + Mo/Mn Metallized + plating Ag

|

|

|

Ceramic + Mo/Mn Metallized + plating Au

|

|

|

Ceramic + printing Ag

|

|

Compared with the above several processes, the sputtering coating method is not only environmentally friendly, but also has a

simple process and low cost, and is the main development direction of the metallization process in the future. The quality of

ceramic metallization mainly depends on the quality of the ceramic itself and the metallization process. The specific influencing

factors include metallization formula, metallization temperature and holding time, metallization microstructure, metallization

coating thickness and coating method.

Alumina Metallized Ceramic Parts:

– Electrical transmission and distribution

– Electronics industry

– Textile machinery

– Defense

– Medical electronics

– Automobile industry

– Sealing

– Solid Oxide Fuel Cells

– High temperature application

– We can supply the products according to customer’s drawings, samples and performance requirement.

– Electronics industry

– Textile machinery

– Defense

– Medical electronics

– Automobile industry

– Sealing

– Solid Oxide Fuel Cells

– High temperature application

– We can supply the products according to customer’s drawings, samples and performance requirement.