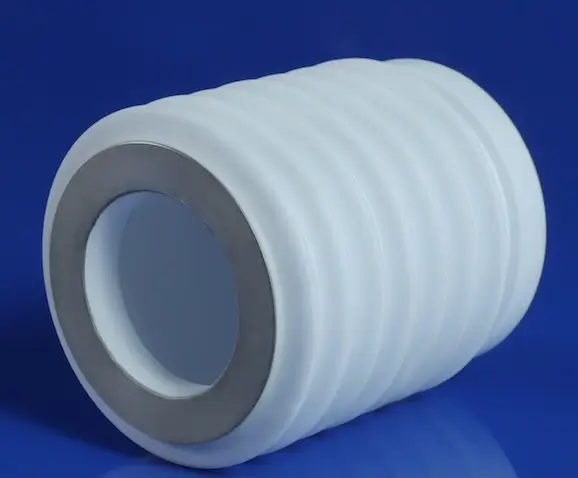

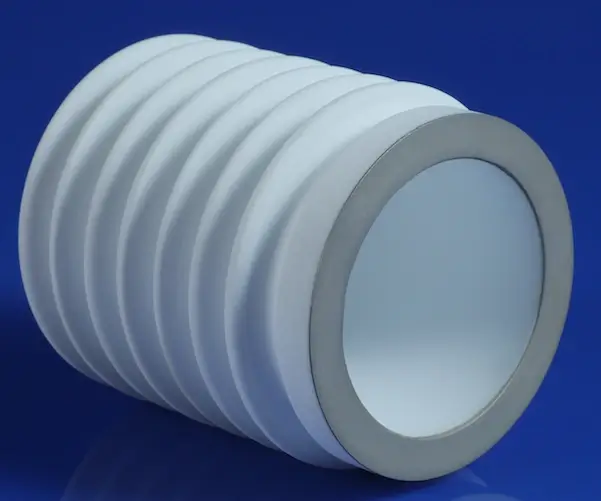

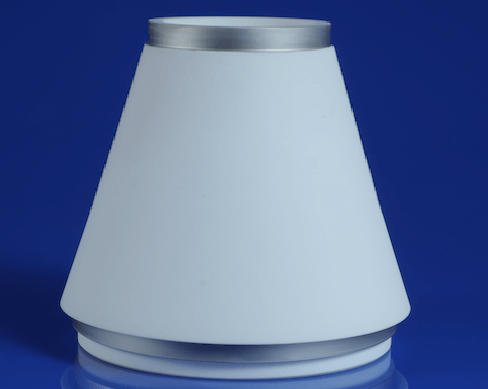

Metallized ceramic tube

Meetcera Technical Ceramics produces reliable medical X-ray components—including anodes, cathodes, complete X-ray tubes, and getter assemblies—using advanced ceramic-to-metal sealing technology. We combine high-purity alumina ceramics with various metal components, achieving hermetic sealing through molybdenum-manganese metallization and brazing processes.

Main Product Types

- Anode and Cathode assemblies

- Complete X-ray Tubes

- Getter Assemblies

- High-voltage insulators, feedthroughs, and custom ceramic-to-metal components

Key Performance Features

- Superior hermetic sealing, significantly reducing leak risk

- Excellent thermal shock resistance and high-temperature stability

- Flexible design with no size limitations, supporting higher power margins and enhanced safety factors

- Outstanding electrical insulation and high dielectric strength, ideal for high-voltage and high-vacuum environments

- Repeatable and consistent manufacturing processes, ensuring cost competitiveness and batch reliability

Application Scenarios

- Medical CT Scanners: High-power rotating anode tubes with reliable high-voltage insulation and vacuum sealing.

- Digital Radiography (DR / DRF) :Stable, long-life performance for frequent high-frequency exposures in fixed and mobile systems.

- Mammography: Ultra-reliable components for high-precision, low-dose imaging and strict safety standards.

- Interventional Radiology (C-arm / DSA): Thermal stability and hermetic sealing for continuous high-power operation in mobile and fixed systems.

FAQ

1.How much longer can the X-ray tube life be extended?

With superior hermetic sealing, excellent thermal shock resistance, and higher power margins, our components significantly extend tube lifespan and reduce maintenance compared to conventional designs.

2.Can the size and shape be customized?

Yes, we offer fully custom designs with no size restrictions, including complex geometries, tailored precisely to your specifications and application requirements.

These components significantly extend X-ray tube lifespan, reduce maintenance needs, and improve overall imaging equipment performance and patient safety. Meetcera provides a full-chain solution—from material selection to complete custom assembly—tailored to meet the unique challenges of the medical X-ray market.

Welcome to contact our application engineers to discuss your specific requirements. With decades of expertise, we will deliver the optimal customized solution for you.