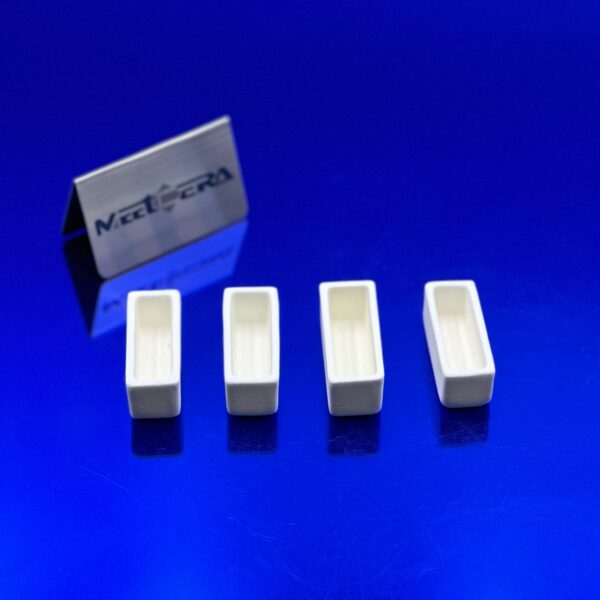

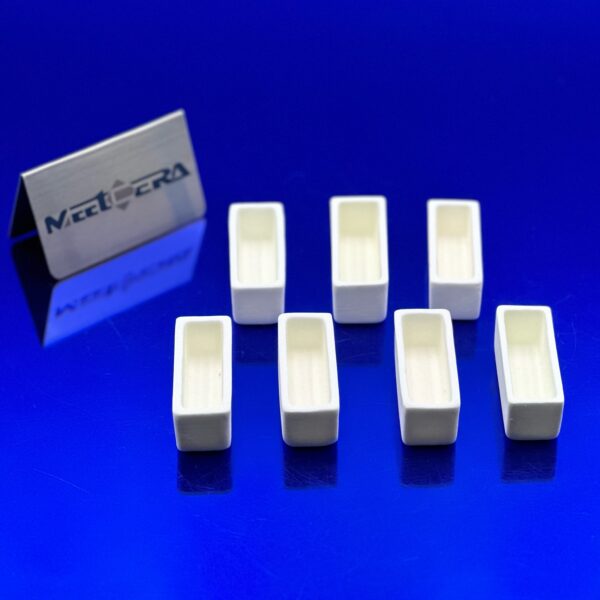

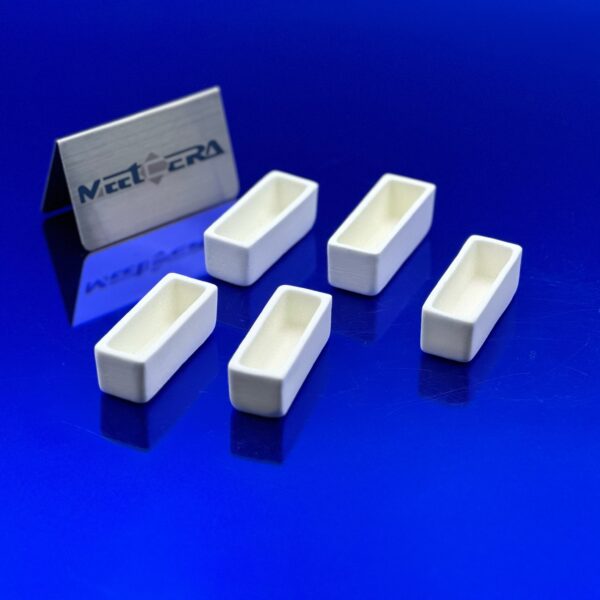

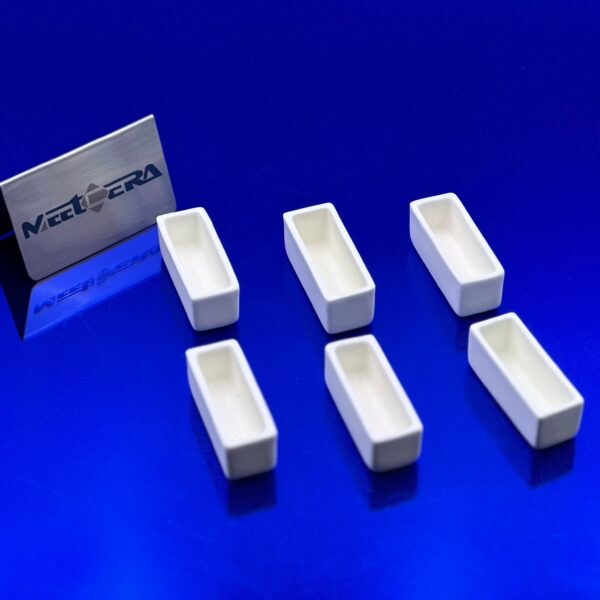

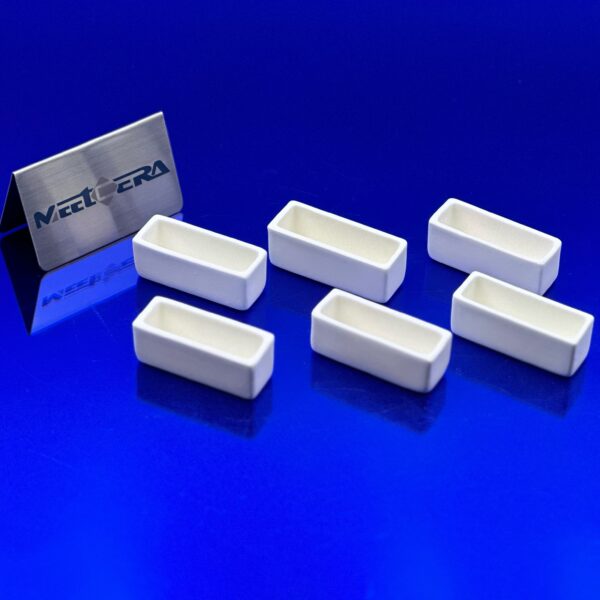

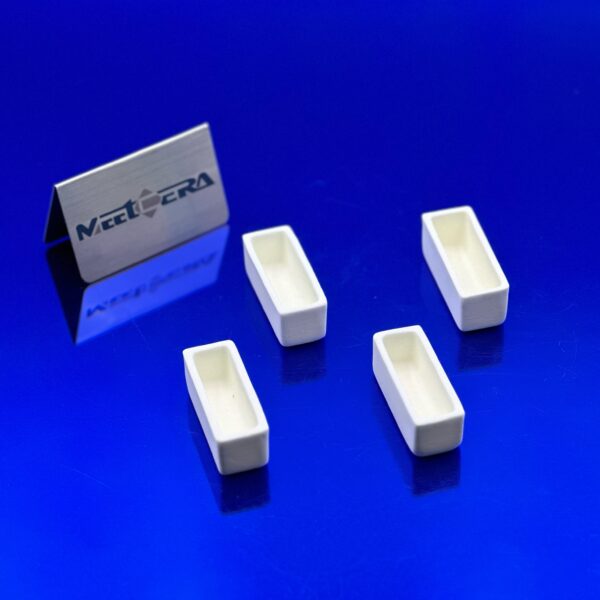

Magnesium oxide crucible: It can be used for ultra-high temperature processing of metals, slags, and superconductor compounds. MgO ceramics are fully fired and have a high-density, fine-grained microstructure. It provides an alternative to alumina because it exhibits better chemical resistance and is inert.

Shape: Conical and arc, cylindrical, oval, square and rectangular shapes, and with many special shapes, the maximum size is 450 mm. From 5 ml to 2000 ml irregular shape, larger capacity can be customized. Usage: Most applications such as metalworking/molten glass, rapid thermal cycling, gemstone purification in the jewelry industry require ceramics to be impermeable and porous forms can also be produced to order.

|

Place of Origin

|

Fujian, China

|

|

Type

|

ceramic crucible

|

|

Application

|

Industrial Ceramic

|

|

Brand Name

|

Meetcera

|

|

Processing Service

|

Cutting, Punching, Moulding

|

|

Product name

|

mgo crucible

|

|

Material

|

Magnesium oxide

|

|

Purity

|

99.5%

|

|

Shape

|

rectangular

|

|

Color

|

White

|

|

Max temperature

|

1800℃

|

|

Feature

|

High thermal stability

|

|

Advantage

|

Fast Delivery Date

|

Merit: 1. Energy saving: 10-20% 2. The preheating time is short, there is no oven, free sintering, and the use can be directly smelted by electricity. 3. High refractoriness, a circle of induction coil pressed at the bottom, the furnace volume is larger than the traditional handmade, the effective power is higher, and the speed of the furnace is significantly improved. 4. Quick and easy installation and removal 5. The furnace installation and assembly greatly improves the labor productivity and effectively reduces the labor intensity. 6. Improve the quality of molten steel. The product has high refractoriness, good thermal stability, high temperature erosion resistance of molten steel, and greatly reduces molten steel slag. 7. Long service life: This product adopts the best particle size level, has high-performance composite materials, and adopts pressure molding, so the life and stability of the furnace are greatly improved. 8. Safety in use: In the event of a malfunction, the outer layer of the furnace (safety lining) can provide safety, effectively eliminating the accident of wearing out the oven.