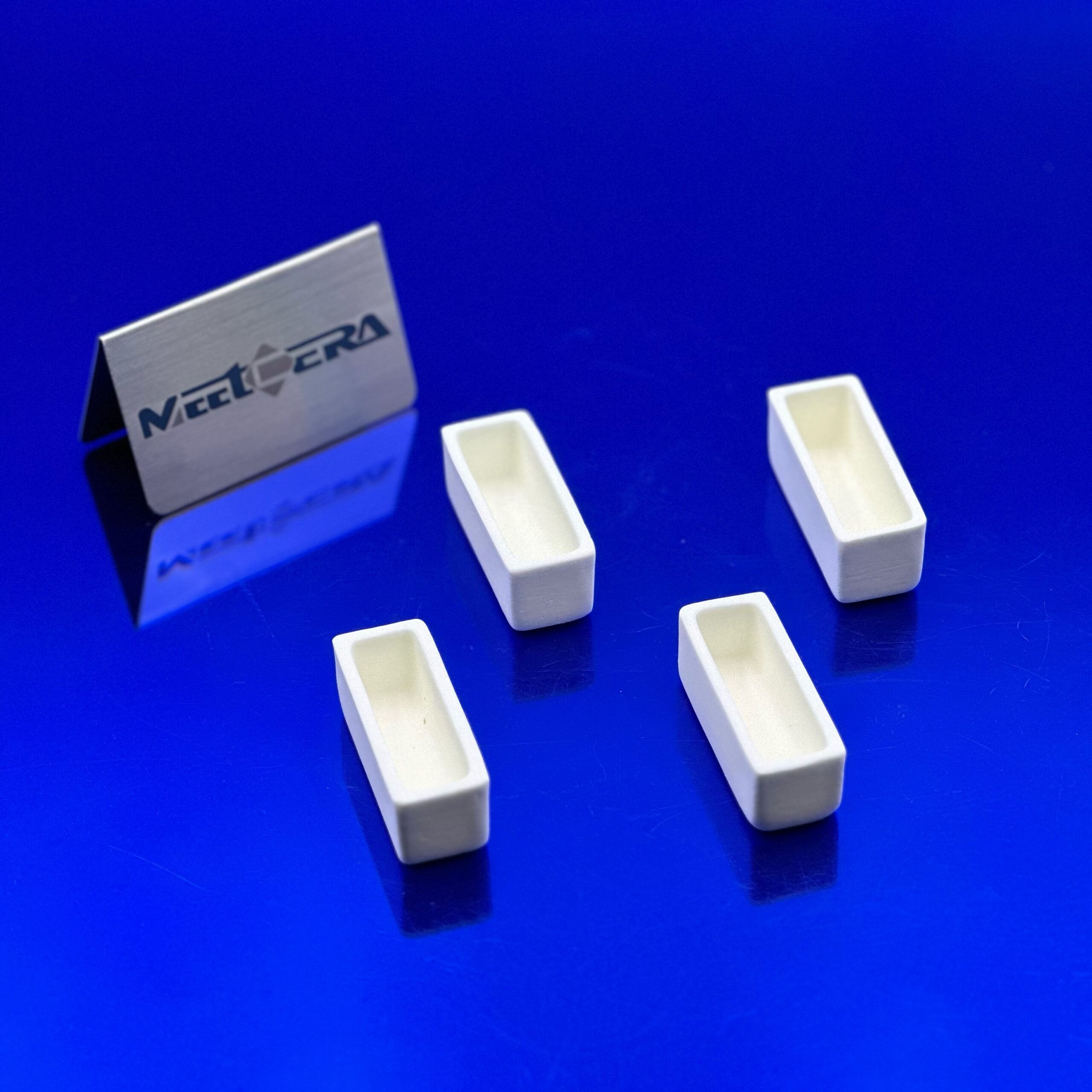

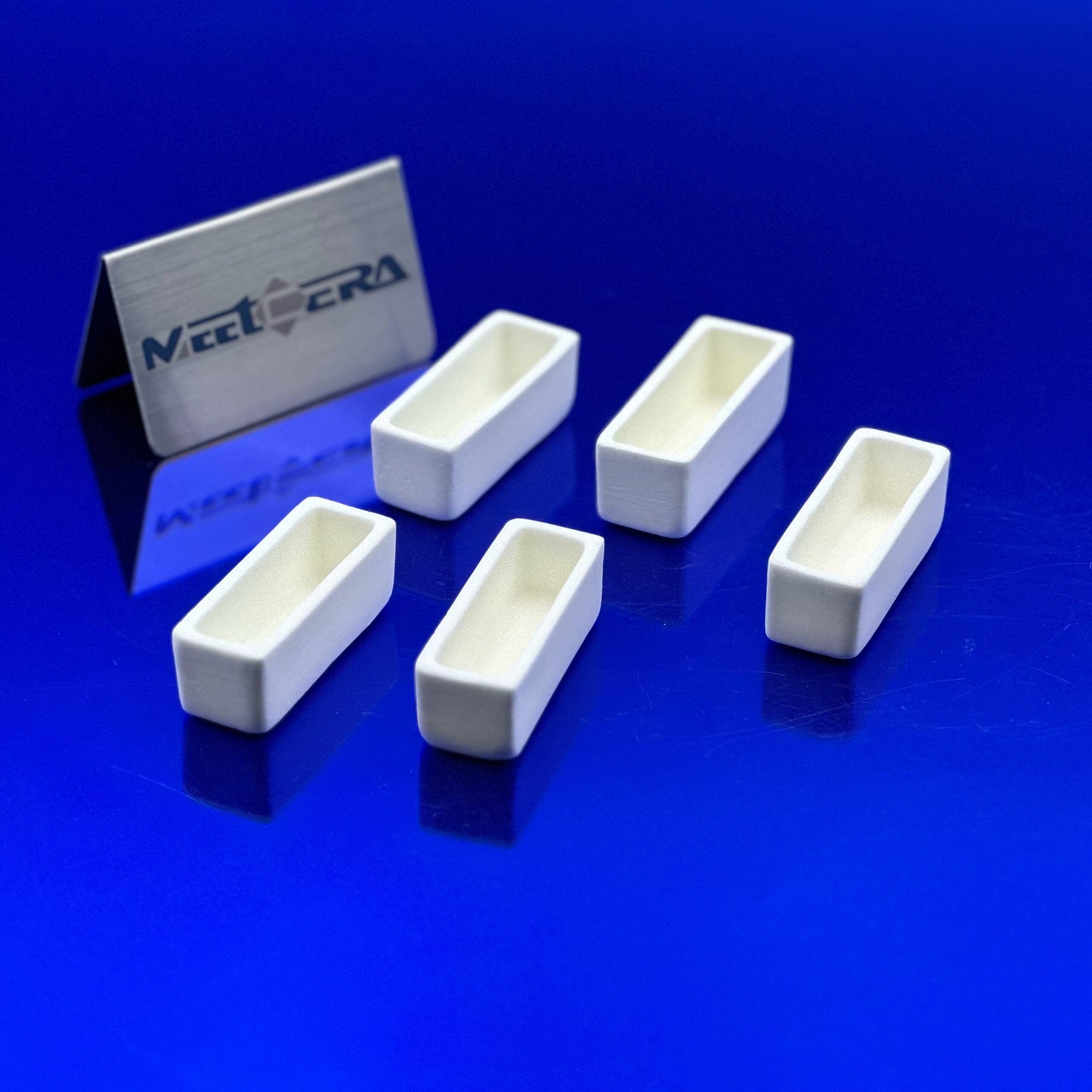

MgO Ceramic Crucible

Made from high-purity magnesium oxide (MgO) through precision forming and high-temperature sintering, Meetcera MgO crucibles feature a fully fired, high-density, fine-grained microstructure. They are ideal for ultra-high temperature processing of metals, slags, and superconductor compounds. MgO ceramics provide a superior alternative to alumina crucibles due to their better chemical resistance and inertness, especially in alkaline or extreme-temperature environments.

Key Features & Benefits

- Ultra-High Temperature Resistance: Maximum service temperature up to 1800°C

- Excellent Corrosion Resistance: Highly resistant to alkaline melts, metal slags, precious metals, and radioactive materials; chemically inert

- High Purity: MgO content 99%, minimizing sample contamination

- High-Density Microstructure: Fully fired for low porosity and superior durability

- Strong Thermal Stability: Excellent thermal shock resistance and uniform heating

- Superior Electrical Insulation: High volume resistivity at elevated temperatures

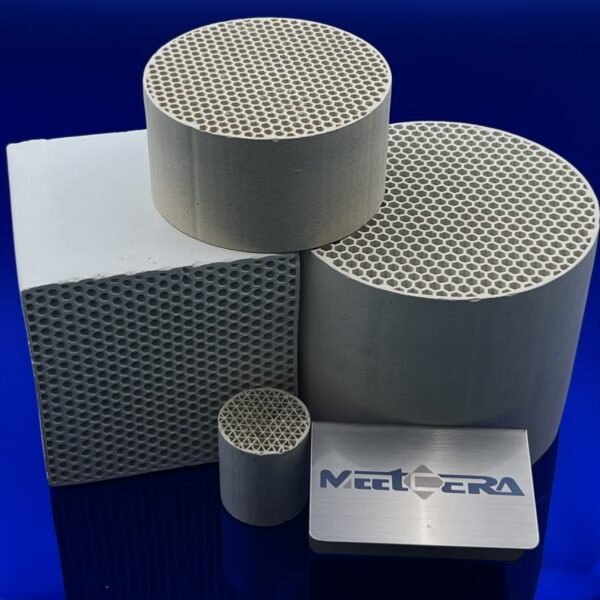

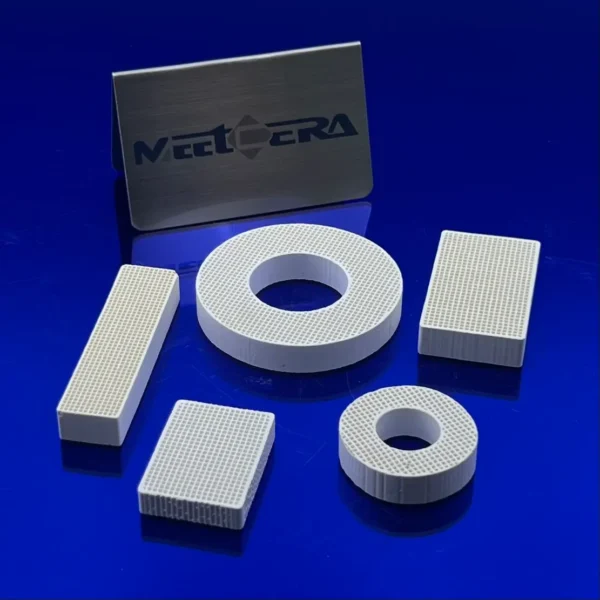

Available Shapes:

Conical and arc, cylindrical, oval, square and rectangular shapes, plus many special shapes. Capacities range from 5 ml to 2000 ml. Larger capacities and irregular shapes are available upon request.

Main Applications:

- Ultra-high temperature melting of metals, slags, and superconductor compounds

- Metalworking and molten glass

- Precious metals melting (platinum, rhodium, iridium, etc.)

- Non-ferrous metals & alloys (copper, aluminum, zinc, nickel, etc.)

- Gemstone purification in the jewelry industry

- High-temperature chemical experiments, rapid thermal cycling, molten salt electrolysis

- Semiconductor, electronics, vacuum furnace processes, and laboratory analysis

Usage Notes:

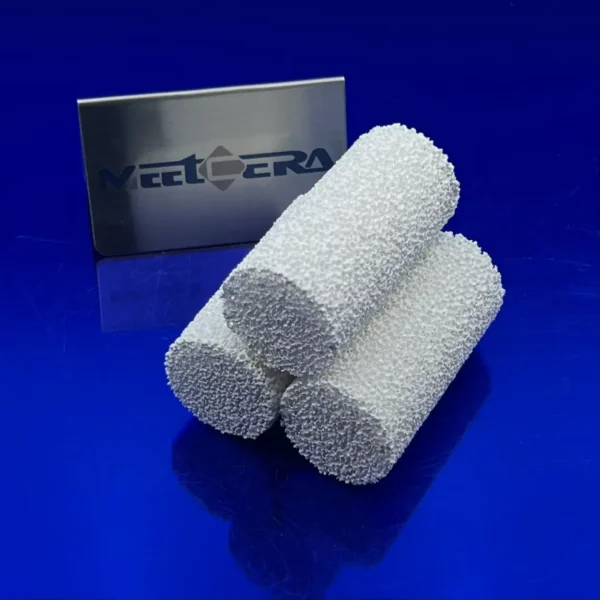

Most applications such as metalworking, molten glass, rapid thermal cycling, and gemstone purification require impermeable ceramics. Porous forms can also be produced to order.

- Avoid prolonged exposure to strong acids

- Heat and cool gradually to maximize service life

- Allow natural cooling after use; avoid sudden thermal shock