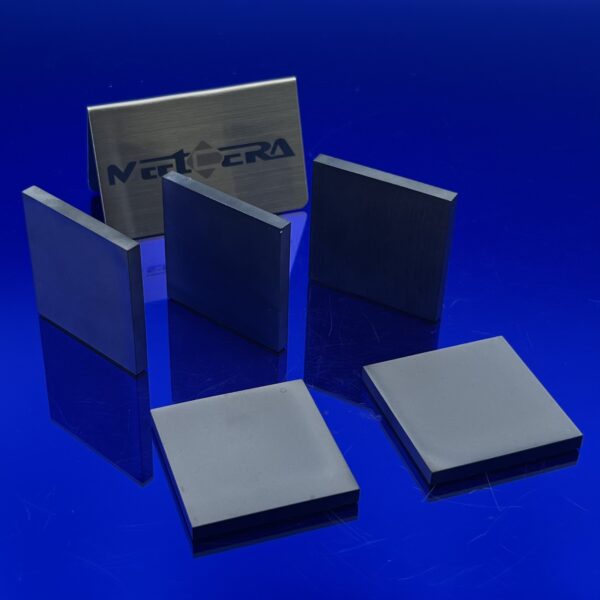

Sintered silicon carbide(SSIC)ceramic is a new kind of ceramic material, with low density,high strength,high hardness,high

temperature resitance oxidation resistance,corrosion resistance and other excellent performances. Now it's the preferred generalmaterial for mechanical seals,sand jets as well as magnetic pumps,shielding pump component,etc. We produce sintered siliconcarbide ceramics taking high purity sub-micron silicon carbide powder as raw material,according to the advanced formula importedfrom japan,through the spray granulation pressure molding and high temperature vacuum sintering.

temperature resitance oxidation resistance,corrosion resistance and other excellent performances. Now it's the preferred generalmaterial for mechanical seals,sand jets as well as magnetic pumps,shielding pump component,etc. We produce sintered siliconcarbide ceramics taking high purity sub-micron silicon carbide powder as raw material,according to the advanced formula importedfrom japan,through the spray granulation pressure molding and high temperature vacuum sintering.

Silicon Carbide Ceramic Advantage

1.silicon carbide is lightweight, dense, almost as hard as diamond, resistant to wear.

2.High mechanical strength:

The bending strength is four times that of recrystallized silicon carbide, twice that of nitride bonded silicon carbide, and 50%higher than that of reaction bonded silicon carbide.

3.Excellent thermal shock resistance:

Due to the excellent thermal conductivity, consistently low thermal expansion coefficient and minimizing internal temperaturegradient, SiC has excellent thermal shock resistance and can be more adaptable to the rapid heat cycling than other materials.

4.Super high temperature stability:

SiC hardly change with temperature, from close to absolute zero up to 1700℃ even under load, that is not suitable for othermaterials.

5.Excellent oxidation resistance:

sintered SiC is more stable in long term applications because it is more oxidation resistant for its high purity and high

density.A protective layer of SiO2 is formed on the surface of SiC which slows the oxidation process, which can extend the life ofthe product.

density.A protective layer of SiO2 is formed on the surface of SiC which slows the oxidation process, which can extend the life ofthe product.

6.SiC displays an extremely universal high corrosion resistance in acidic, alkali, basic media and oxidants -even at hightemperatures.

|

1) Purity :

|

from 99% to 99.9%

|

||

|

2) Types

|

Hexagon Tilesm, Rectangle Tiles, Curved Rectangle Tiles, Single Curved Plates

|

||

|

3) Shapes available:

|

Square, hexagonal, cylinder, rectangle, single-curved plate, cut-angle tile and so on

|

||

|

4) Sizes: |

50*50mm; 100*100mm; 50*25mm; 100*50mm (specific sizes are also available)

|

||

|

Hex tile flat to flat 20mm,30mm,40mm

|

|||

|

5)Material: |

Alumina 99(99% Alumina)

|

||

|

Sintered Silicon Carbide(SSiC)

|

|||

|

Boron Carbide(B4C)

|

|||

|

6) Hardness:

|

up to 1500

|

||

|

Properities

|

|||

|

Density:

|

3.05-3.15g/cm3

|

||

|

Porosity:

|

≤0.1%Hardness

|

||

|

HRV:

|

≥ 20 Gpa

|

||

|

Fracture Strength:

|

≥ 320Mpa

|

||

|

Elestic Modulus:

|

≥360GpaFracture

|

||

|

Toughness:

|

2-3Mpa M1/2

|

||