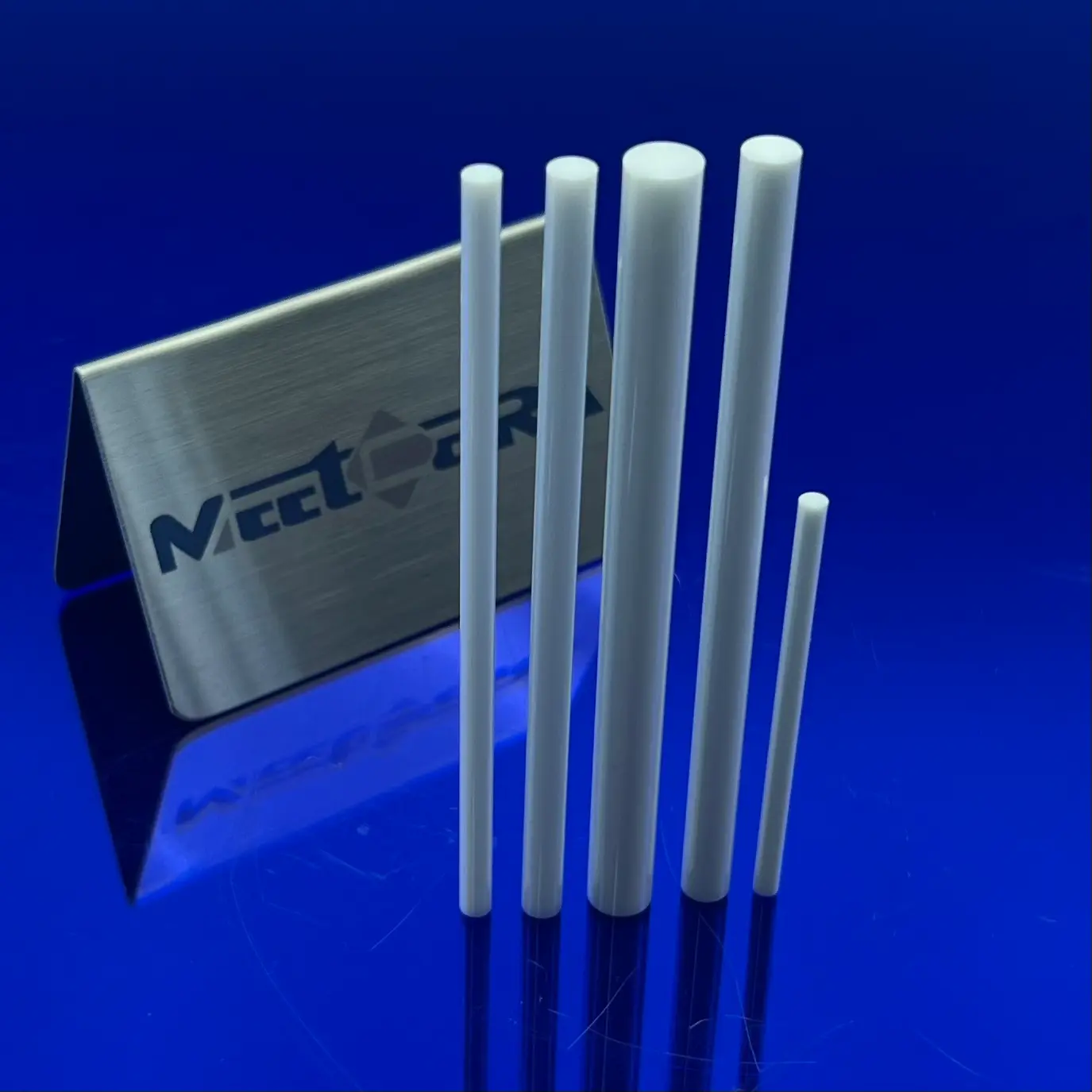

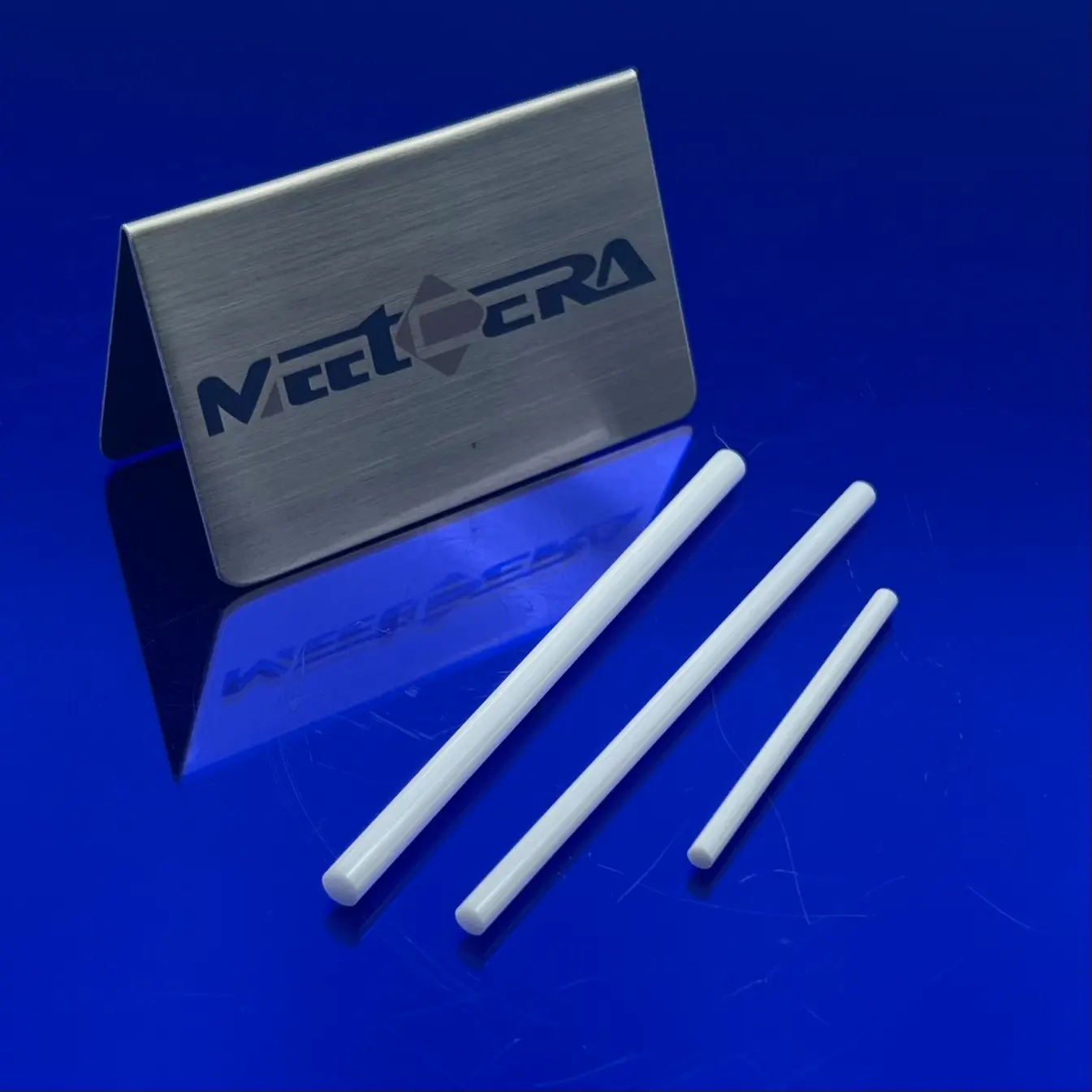

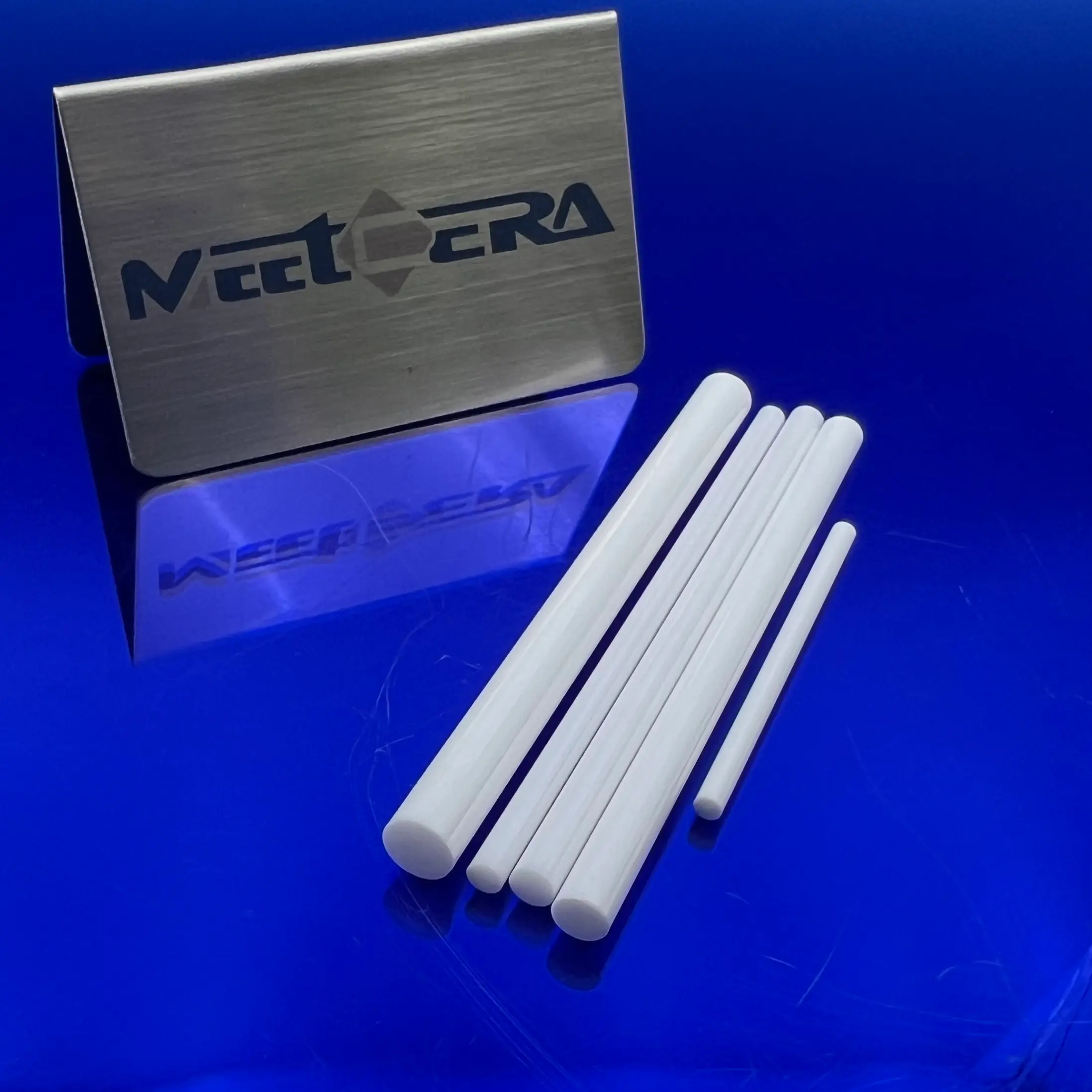

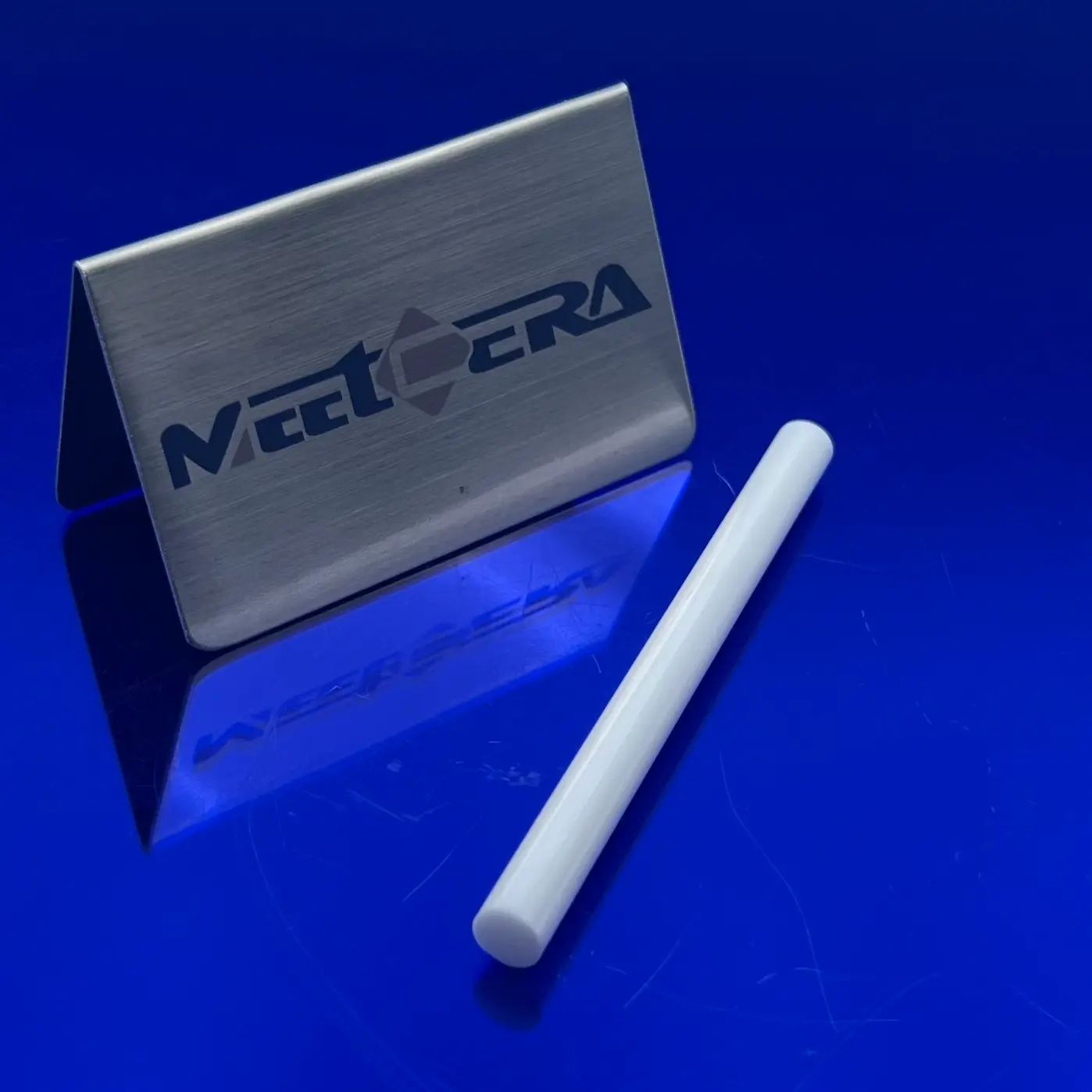

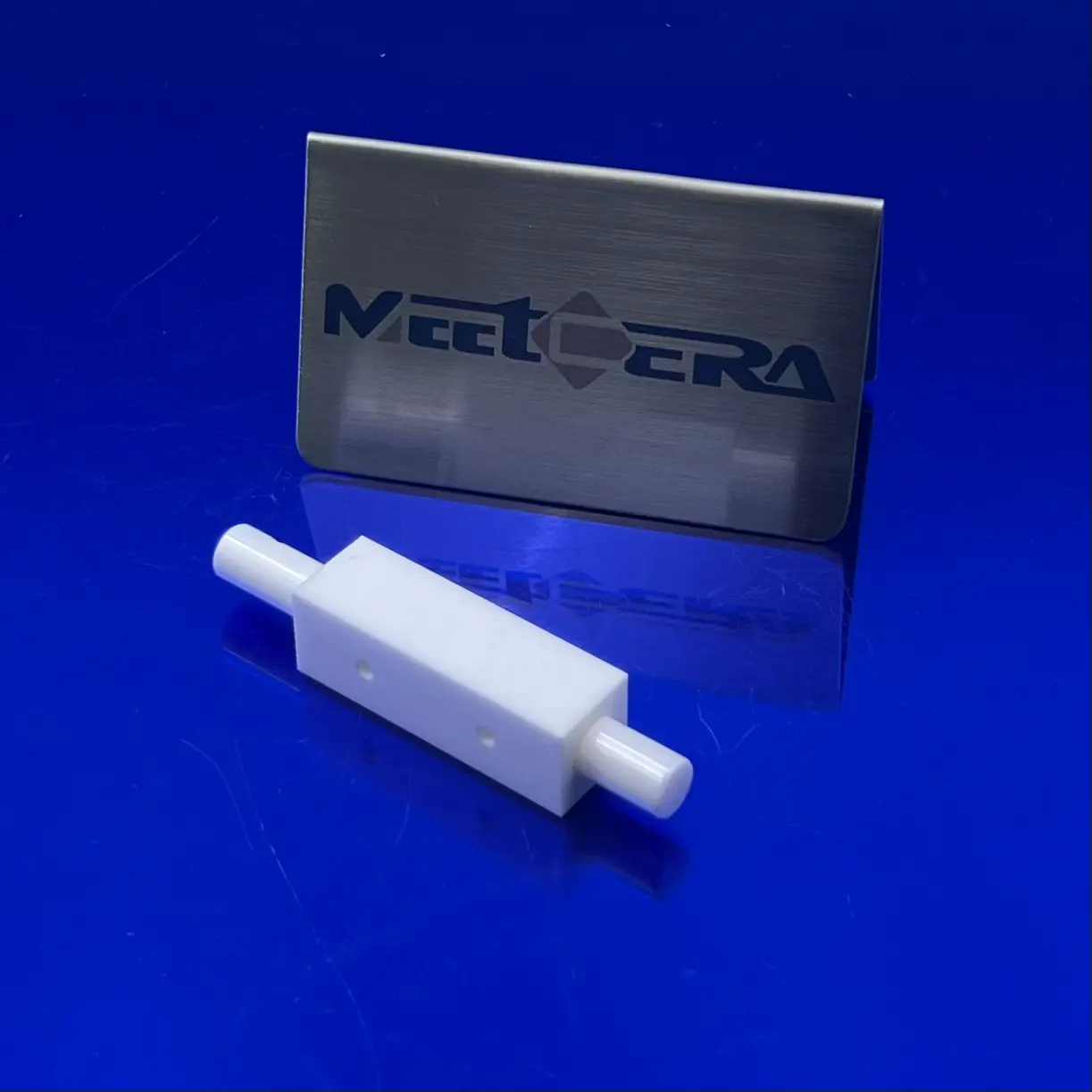

Solid Zirconia Ceramic Rod

Zirconia ceramic rod is a high-performance structural ceramic made from high-purity zirconium dioxide (ZrO₂), stabilized with yttria (Y-TZP). Known as “the steel of ceramics,” it delivers exceptional strength, toughness, and wear resistance. Produced via isostatic pressing, high-temperature sintering, and precision machining, it excels in demanding applications.

Key Features:

- Superior toughness & strength: Fracture toughness ≥8–10 MPa·m¹/², flexural strength ≥1000 MPa — resists brittle failure

- Excellent wear resistance: Hardness HRA ≥88, outperforms alumina and most metals

- Outstanding corrosion resistance: Withstands strong acids, alkalis, seawater, and molten metals

- High temperature & low thermal expansion: Up to 2200°C+, thermal expansion close to metals, good thermal shock resistance

Main Application Areas:

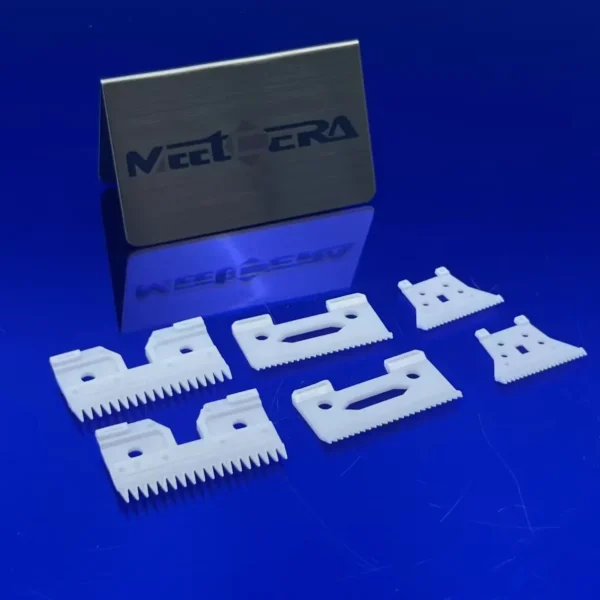

- Precision Machinery: Shafts, plungers, bearings, positioning pins, guide rods

- Medical & Dental: Implant abutments, drill handles, surgical components

- Electronics & Semiconductor: Insulating pins, fiber optic ferrules, probe holders

- Chemical & Fluid Control: Valve cores, pump pistons, nozzles, stirring rods

Frequently Asked Questions

Q1: How does zirconia compare to alumina ceramic rods?

A: Zirconia offers 3–5× higher fracture toughness and better impact resistance, plus superior wear performance. It is denser (≈6.0 vs 3.9 g/cm³) and more expensive, making it ideal for high-reliability needs.

Q2: What are the smallest/largest sizes and tolerances you can produce?

A: Diameters 0.5–60 mm, lengths up to 1000+ mm. Standard tolerance ±0.01 mm; precision can reach ±0.005 mm (depending on size and ratio). Contact us for ultra-fine or extra-long specs.

Q3: Why are some rods white and some black? Can you make black?

A: Yes, black is available. White is natural zirconia color; black comes from added colorants or reduction processes. Performance is essentially the same—black is often chosen for appearance or laser marking.

If you need custom sizes, surface finishes (mirror polish, sandblasted, coated), pricing, or samples, just let us know — fast response and full customization available!