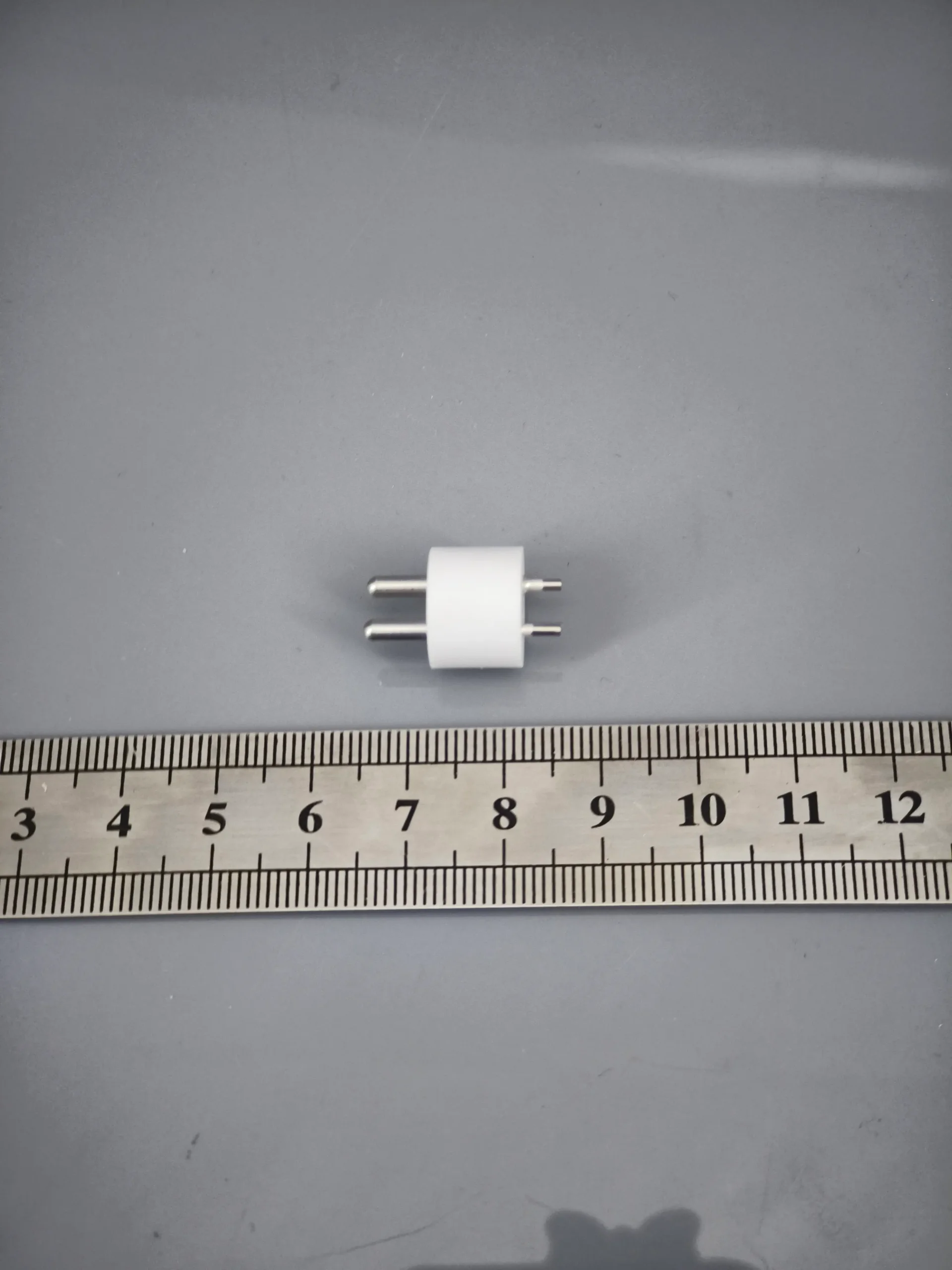

Vacuum Rotary Feedthrough

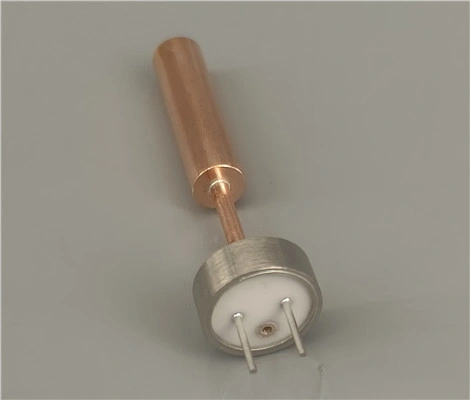

Vacuum feedthroughs are sealed connection devices designed for high and ultra-high vacuum (UHV) environments. They allow reliable transmission of power, signals, fluids, or motion from atmospheric to vacuum side without compromising system integrity. This product uses advanced ceramic-to-metal sealing for ultra-low leak rates (≤1×10⁻¹⁰ Pa·m³/s), ideal for semiconductor processing, particle accelerators, vacuum coating, surface analysis, and electron microscopy.

Key Features:

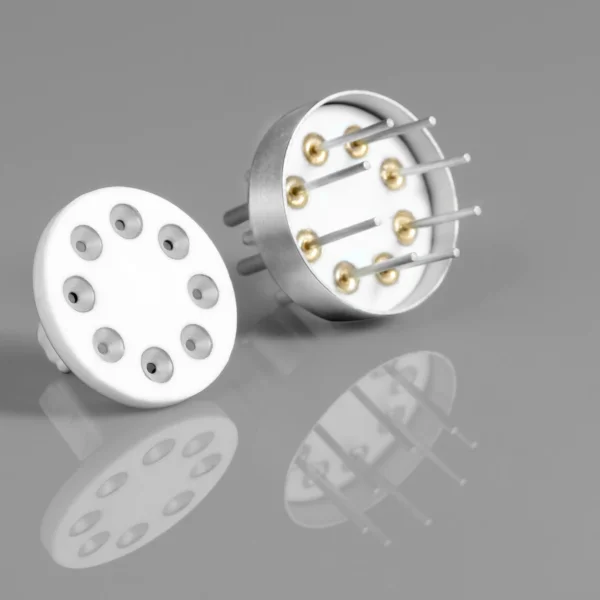

- High-Reliability Sealing: Stainless steel flanges (CF/KF/ISO) with high-purity ceramic insulators; UHV-compatible, bakeout up to 450°C.

- Flexible Configuration: Multi-pin options; voltage up to 50kV; current up to 1000A.

- Multiple Types: Power, coaxial (SMA/BNC/SHV), thermocouple, fluid; customizable single/double-ended, grounded/floating.

- Harsh Environment Resistance: Handles high temperature, pressure, and corrosive gases.

- Easy Installation: Standard flanges; compatible with major vacuum systems; quick-plug connectors supported

Application Areas:

- Semiconductor manufacturing and PVD/CVD equipment

- Scientific research (electron microscopes, mass spectrometers, accelerators)

- Vacuum furnaces, X-ray systems, space simulation chambers

- Medical and analytical instruments

FAQ

1. What is the maximum bakeout temperature?

Standard models: up to 450°C. Custom options available up to 600°C—contact us with your requirements.

2. How to choose flange type (CF, KF, or ISO)?

CF for UHV (best sealing); KF for HV (quick install); ISO for larger/medium vacuum. We'll advise based on your system.

3. Do you support customization?

Yes—pin count, voltage/current, connectors, shielding, materials. Provide specs for a free quote .

This vacuum feedthrough offers superior performance and customization to ensure reliable, leak-free vacuum systems. Contact us for custom needs or questions!