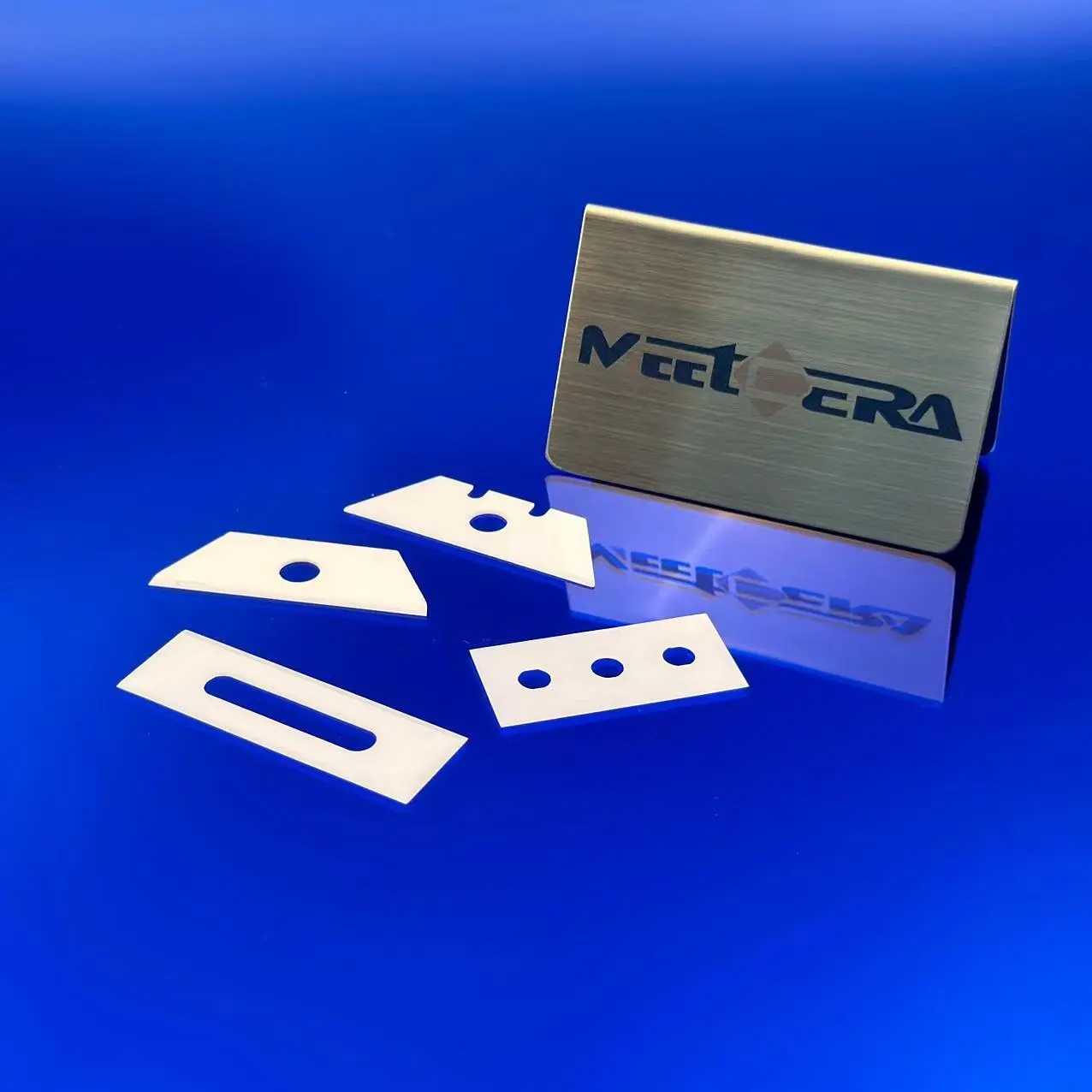

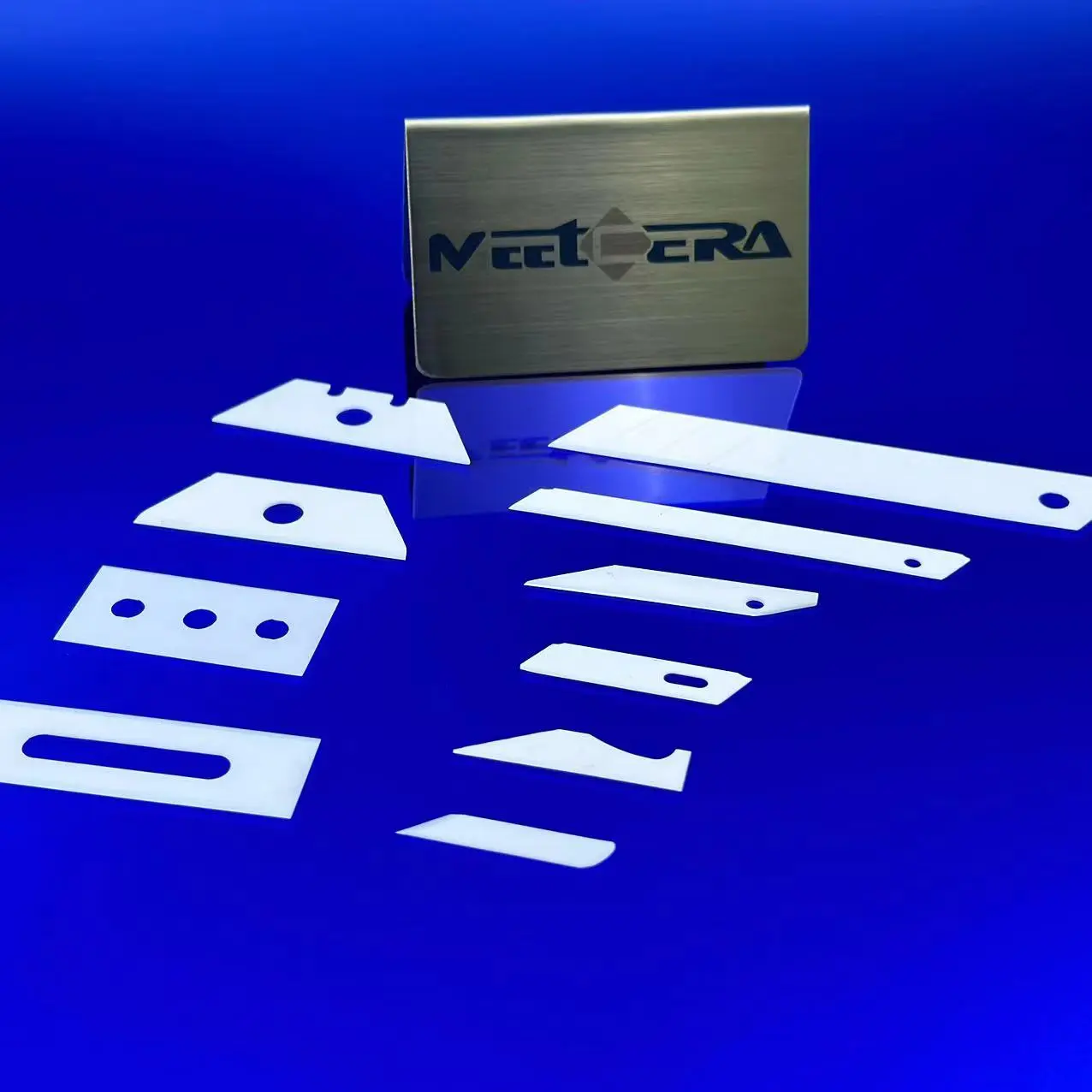

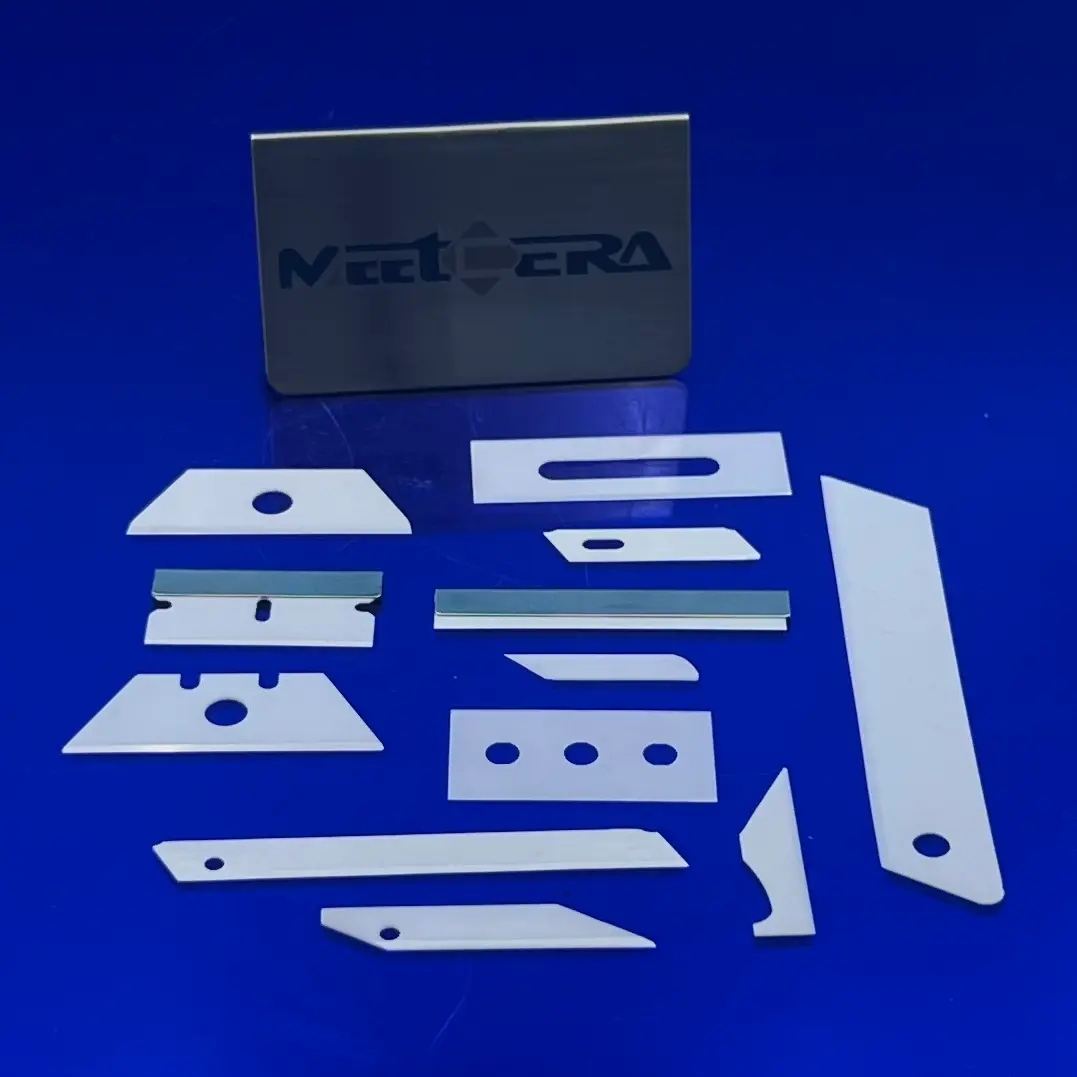

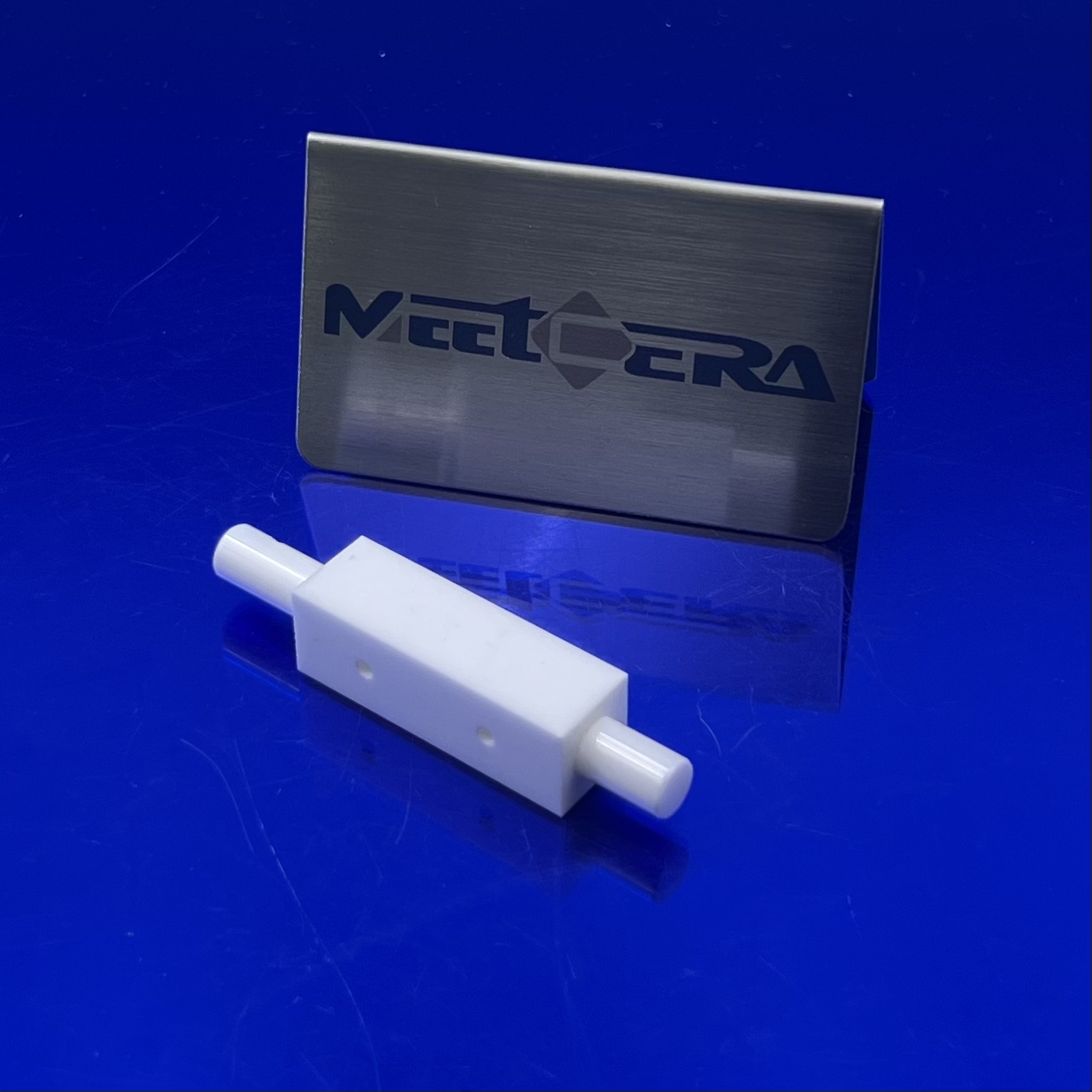

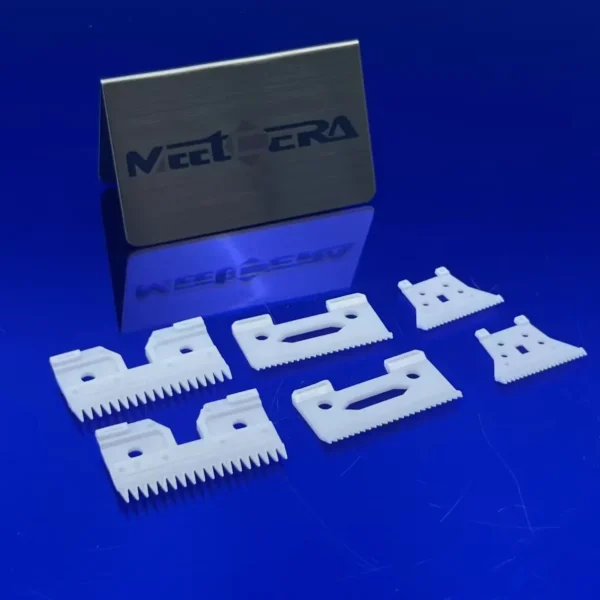

High-Performance Zirconia Ceramic Blades

Made from high-purity using precision forming and high-temperature sintering processes, Meetcera zirconia ceramic blades are specifically engineered for demanding industrial environments, delivering exceptional sharpness, ultra-long service life, and outstanding corrosion resistance.

Key Features

- Ultra-High Hardness: Vickers hardness approx. 12–13 GPa, Mohs hardness ≈8.5–9, second only to diamond

- Ultra-Low Friction Coefficient: Smooth surface for minimal cutting resistance

- Non-Metallic & Non-Magnetic: Completely free of iron and non-conductive

- Superior Chemical Stability: Resistant to strong acids, alkalis, and corrosive media

Core Advantages

- Exceptional Sharpness & Extended Edge Retention Blades remain razor-sharp for extended periods, offering a service life typically 10–100 times longer than traditional steel blades, significantly reducing replacement frequency and downtime.

- Outstanding Corrosion & Wear Resistance Never rusts, no metal ion release, no off-odors — ideal for corrosive or clean environments without contamination risk.

- Smooth Cutting & High-Quality Finish Low-friction surface ensures clean cuts with no burrs or fraying when slitting plastic films, foils, fibers, and other materials, improving product quality and yield.

- High Strength & Fracture Toughness Transformation toughening mechanism provides steel-like toughness combined with ceramic hardness, enabling excellent performance under severe industrial wear and moderate impact.

Product Types

- Standard Series: Rectangular straight blades, circular rotary blades, trapezoidal blades, snap-off blades, deburring blades, etc.

- Pelletizing Blades: High-performance blades for granule cutting

- Slitting Blades: Low-friction blades optimized for films, foils, paper, and textiles

- Custom Series: Any shape, size, thickness, edge angle, color (white/black/blue), and surface finish

Typical Applications

- Pelletizing: Plastic, chemical, and food granule cutting

- Film & Foil Slitting: Plastic films, BOPP, aluminum foil, composite films

- Fiber & Textile Cutting: Synthetic fibers, non-woven fabrics, leather

- Paper & Printing: Precision slitting of labels and tapes

- Electronics & Medical Consumables: Circuit materials, medical packaging

- Aerospace & Composites: Carbon fiber prepreg and high-performance composites

- Replacement of metal blades in high-cleanliness, high-corrosion, or high-wear environments

FAQ

Q1: Can ceramic blades really last 10–100 times longer than steel blades?

A: Yes, when cutting soft to medium-abrasive materials (e.g., films, paper, fibers), service life is typically 10–100 times that of steel, depending on material, speed, and conditions. Avoid cutting hard or high-impact objects.

Q2: Are ceramic blades prone to breaking?

A: Thanks to transformation toughening, toughness far exceeds ordinary ceramics, but they remain brittle. Avoid heavy impacts, drops, lateral prying, or cutting metal/bone/hard objects to minimize fracture risk.

Q3: Can ceramic blades be resharpened?

A: Due to extreme hardness, standard grinding wheels are ineffective. We recommend direct replacement (long life makes this more cost-effective overall). Professional regrinding is available upon request.