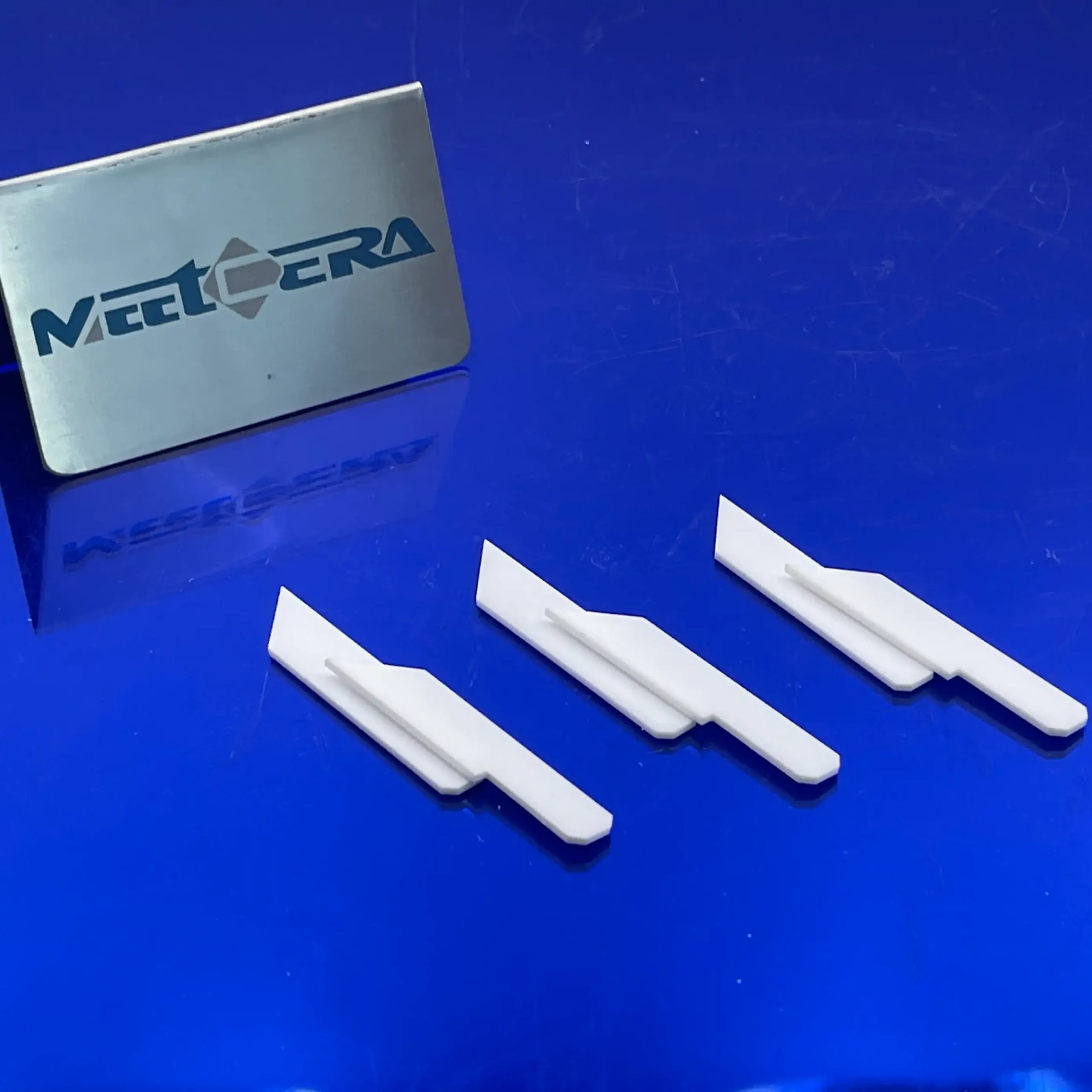

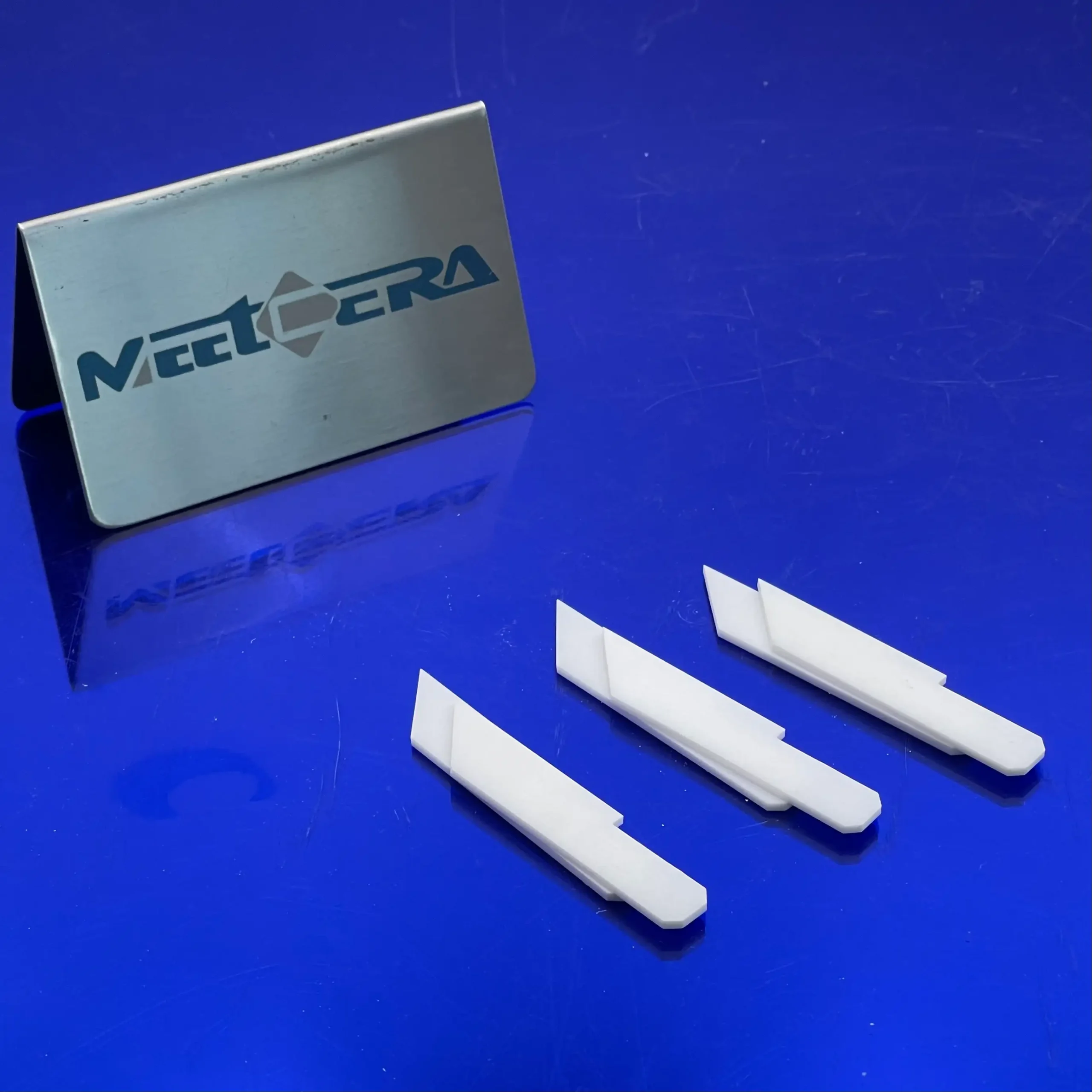

High-Precision Zirconia Ceramic Scraper

Manufactured from premium yttria-stabilized zirconia (YSZ) ceramic using advanced pressing, sintering, and precision edge grinding/polishing processes, Meetcera zirconia scraper blades offer unmatched durability, clean wiping performance, and zero contamination in demanding applications.

Key Performance Highlights:

- Exceptional hardness & abrasion resistance: Far superior to steel or alumina blades, especially against abrasive inks, slurries, or coatings

- Superior chemical inertness: Non-reactive with acids, alkalis, solvents, water-based/UV inks — no corrosion, no metal ion leaching

- High edge sharpness & retention: Maintains consistent, clean metering/wiping over extended runs; minimal streaking or buildup

- Excellent thermal & dimensional stability: Low expansion, good thermal shock resistance, suitable for high-speed or heated processes

Typical Application Scenarios:

- Doctor blades for flexographic printing: Precise ink metering on ceramic anilox rolls, especially with abrasive or high-pigment inks

- Coating & film application: Uniform thin-film deposition in battery slurries, solar cells, functional coatings, lab-scale tape casting

- Precision scraping in electronics & semiconductor: Slurry/ paste removal, wafer processing, or cleanroom-compatible tools

- Laboratory & R&D: Scratch-free scraping of viscous materials, adhesives, paints, or nanomaterials without contamination

Product Performance Specifications:

| Property | Typical Value / Range | Remarks |

|---|---|---|

| Material | Yttria-Stabilized Zirconia (YSZ, ZrO₂ ≥99.5%) | 3–8 mol% Y₂O₃ for toughness & stability |

| Density | 5.9–6.1 g/cm³ | Fully dense, zero open porosity |

| Hardness (Vickers) | 1200–1400 HV | Extreme wear resistance |

| Flexural Strength | 900–1300 MPa | High resistance to bending/breaking |

| Fracture Toughness | 6–10 MPa·m¹/² | Better impact resistance than alumina |

| Edge Radius / Sharpness | <5–20 μm (custom ultra-sharp available) | Precision ground/polished edge |

| Surface Finish (Ra) | ≤0.05–0.2 μm | Mirror polish for low friction |

| Max. Operating Temperature | Up to 1200–1500°C (application dependent) | Excellent thermal stability |

FAQ

Q1: Why choose zirconia ceramic scraper blades over steel or coated metal doctor blades?

A: Zirconia provides dramatically longer life (often 5–20×) in abrasive conditions, complete non-metallic/non-contaminating performance, superior edge retention, and no risk of scoring delicate anilox rolls or substrates.

Q2: What handling precautions are recommended?

A: Avoid mechanical impacts or dropping (ceramic is hard but brittle); use gentle cleaning (ultrasonic or solvent wipe); control thermal gradients (ramp ≤10°C/min if heated); ensure proper blade angle/pressure setup to prevent chipping.

Q3: Can Meetcera customize blade dimensions and edge profiles?

A: Yes — full customization: lengths 10–500+ mm, widths 10–50 mm, thicknesses 0.1–2 mm, various edge geometries (square, beveled, rounded tip), tolerances ±0.01 mm, and special coatings/polishing. Provide drawings for quick quoting.