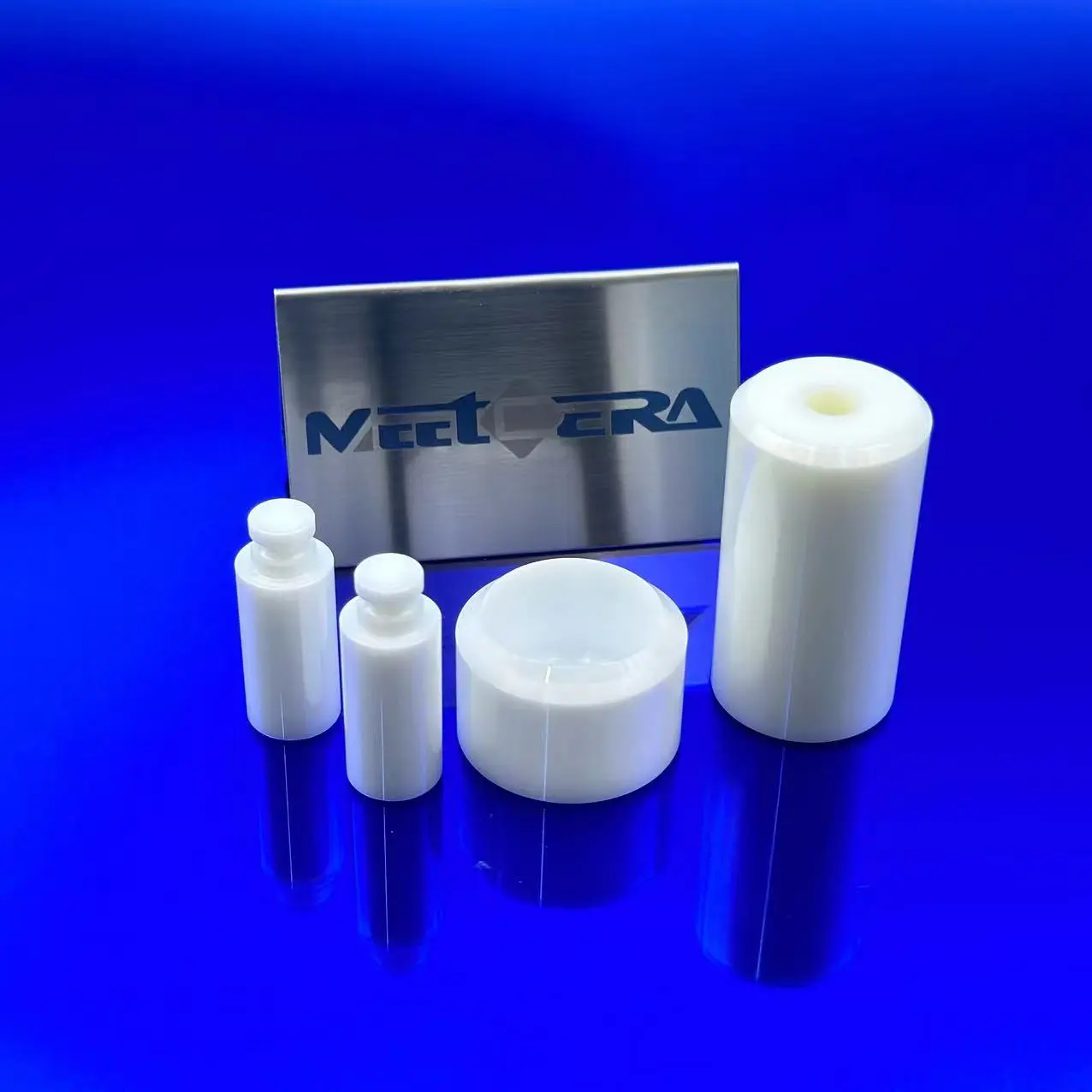

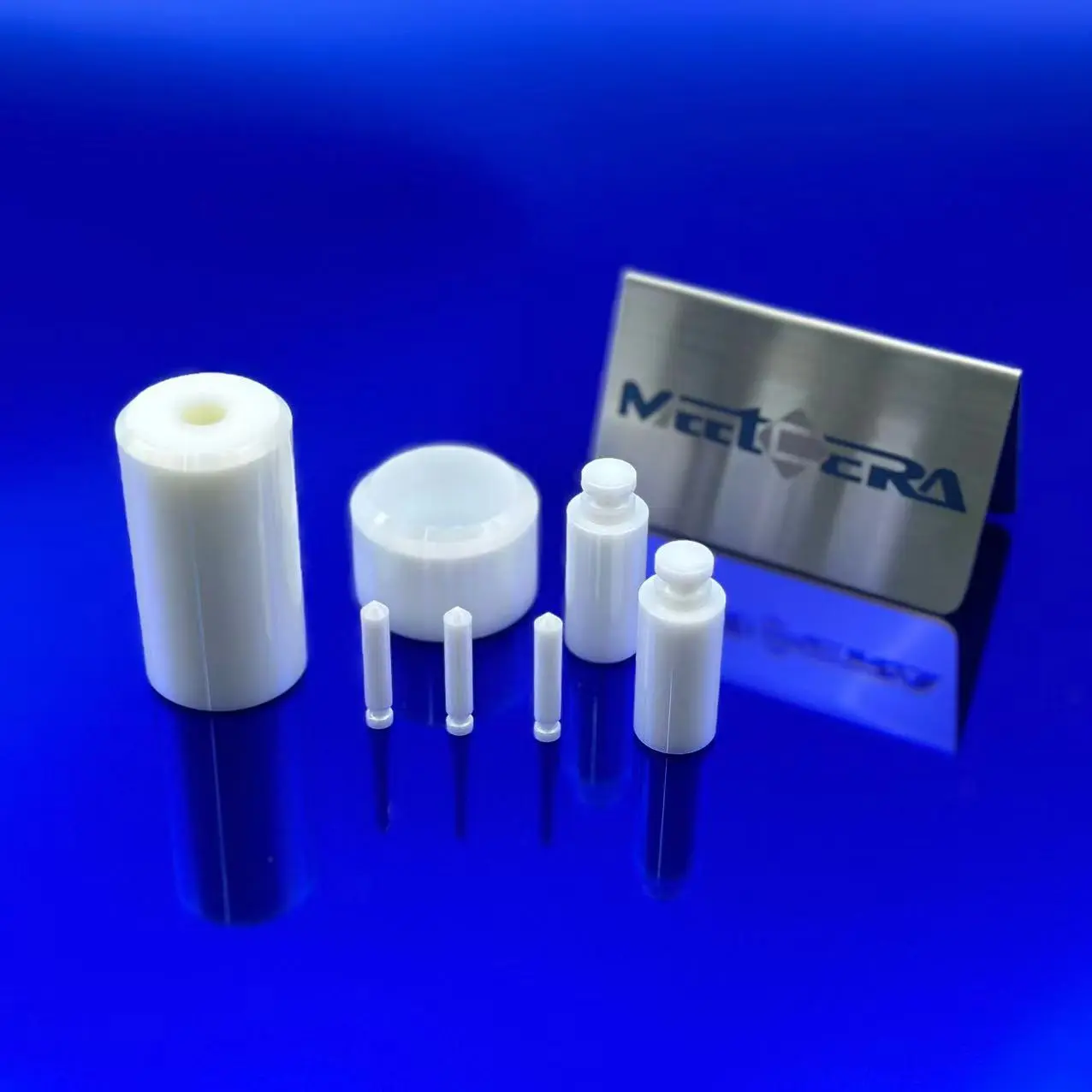

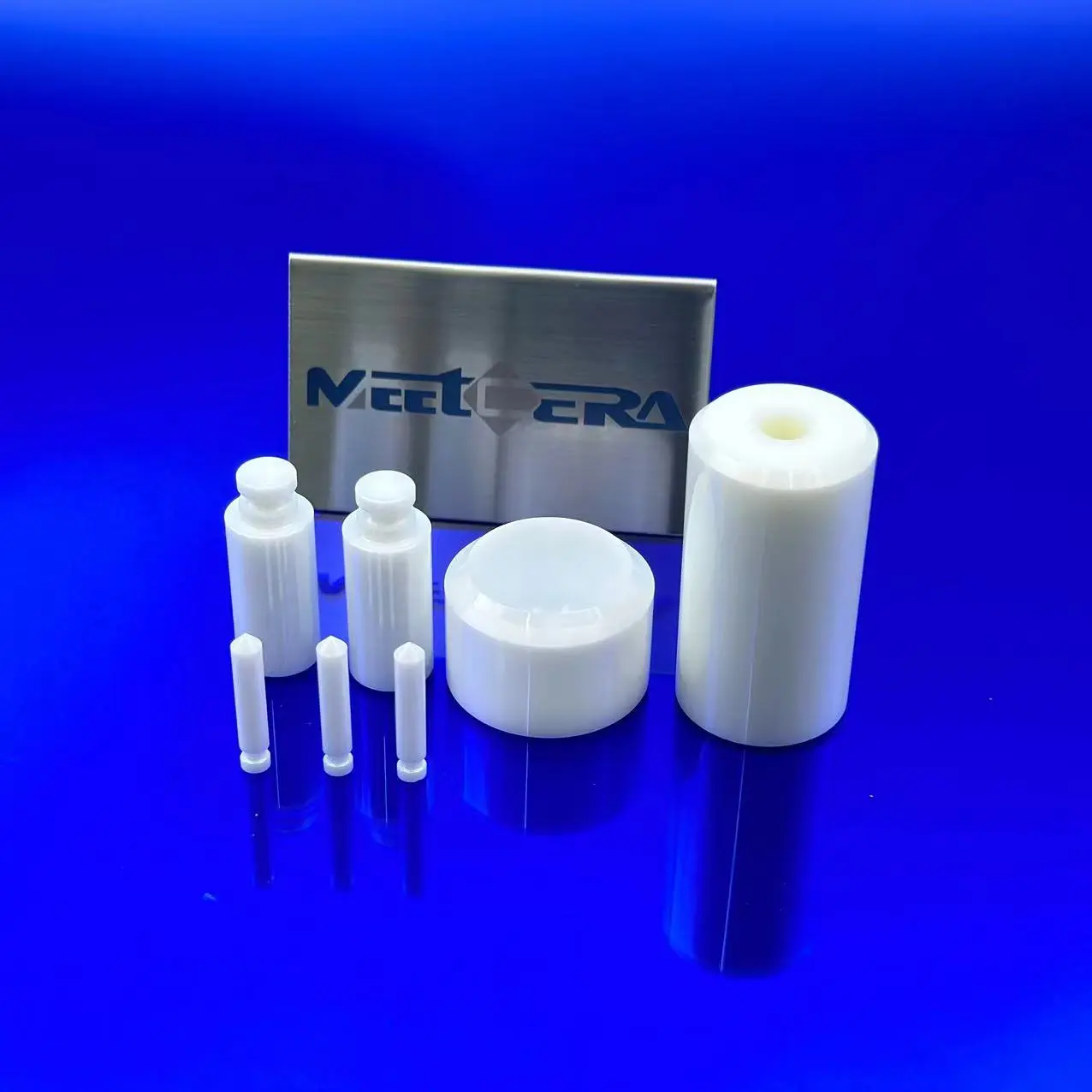

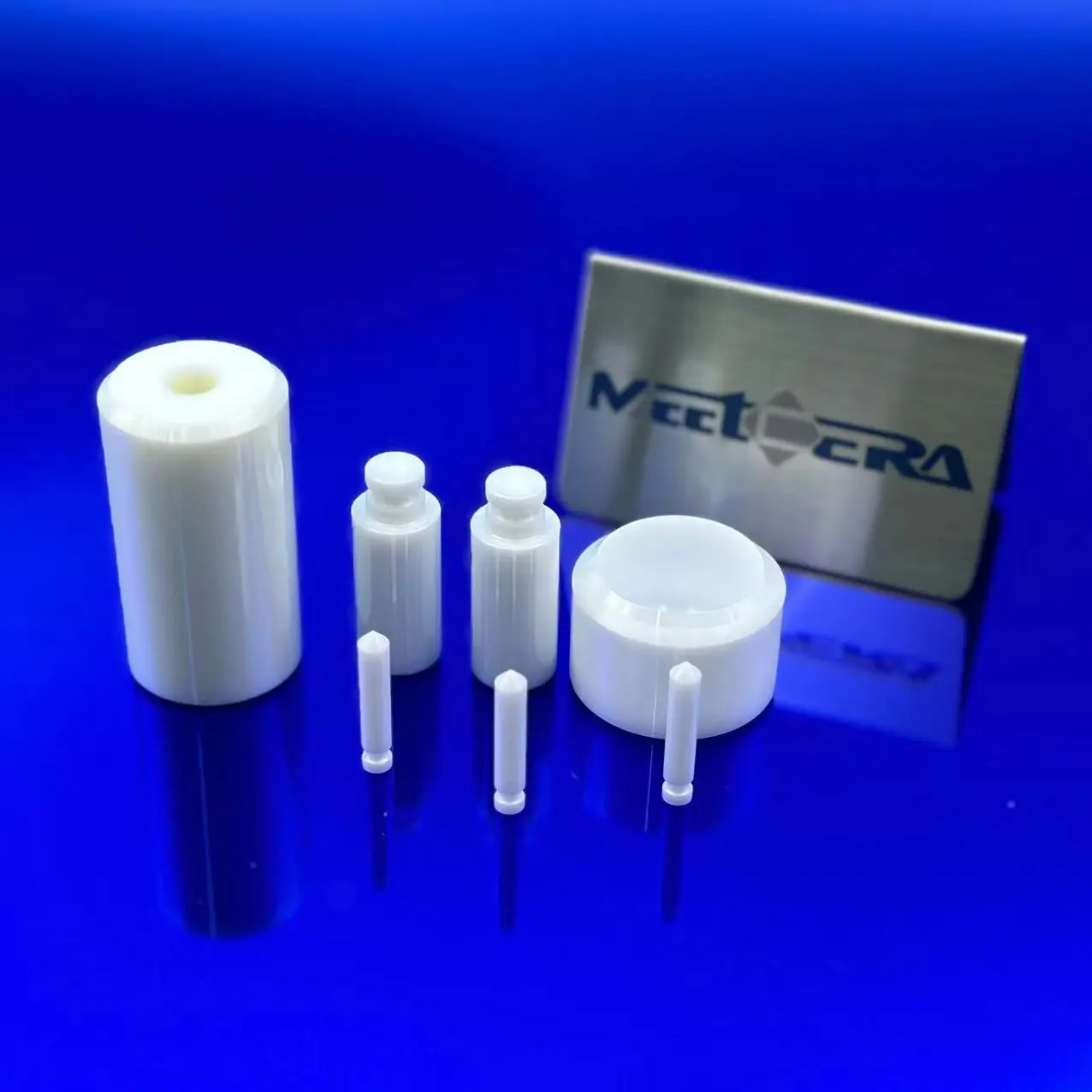

Zirconia Ceramic Shaft Rod

Meetcera zirconia ceramic shafts and plungers feature a bright white, fully dense, mirror-polished finish — precision-machined from high-purity yttria-stabilized zirconia (YSZ). These components deliver outstanding durability, zero contamination, and exceptional performance in aggressive environments.

Key Performance:

- Extreme hardness & superior wear resistance: Outlasts metal, alumina, and most ceramics in abrasive/sliding contact

- High fracture toughness & mechanical strength: Excellent resistance to impact and brittle failure

- Total chemical inertness: Unaffected by strong acids, alkalis, solvents, and corrosive fluids (full pH range)

- Mirror-smooth surface & low friction: Self-lubricating, minimal sticking, precise fit with extended seal life

Typical Application Scenarios:

- High-pressure / metering pump plungers and pistons (dosing, filling, HPLC, semiconductor slurry pumps)

- Precision shafts, guide rods, and wear sleeves in chemical, petrochemical, and pharmaceutical processing equipment

- Non-contaminating components for medical devices, food/beverage filling systems, and biotech fluid handling

- High-reliability rotating or reciprocating elements in semiconductor, optical, and high-vacuum machinery

FAQ

Q1: How do Meetcera zirconia shafts compare to stainless steel or alumina plungers?

A: Zirconia provides dramatically longer life in abrasive/corrosive media, zero metal ion contamination, higher hardness, and better toughness — often 5–10× the service life of metal or alumina equivalents.

Q2: What installation and usage tips apply?

A: Avoid thermal shock (ramp rates ≤10°C/min); prevent edge chipping during handling; ensure proper alignment and minimal side loading; no external lubrication required thanks to inherent low-friction properties.

Q3: Does Meetcera support custom designs?

A: Yes — full customization of diameters (0.5–50+ mm), lengths (up to 600 mm+), features (steps, grooves, threads, through-holes, tapered ends), tolerances (±0.05mm achievable), and mirror polishing. Send drawings for rapid quotation.