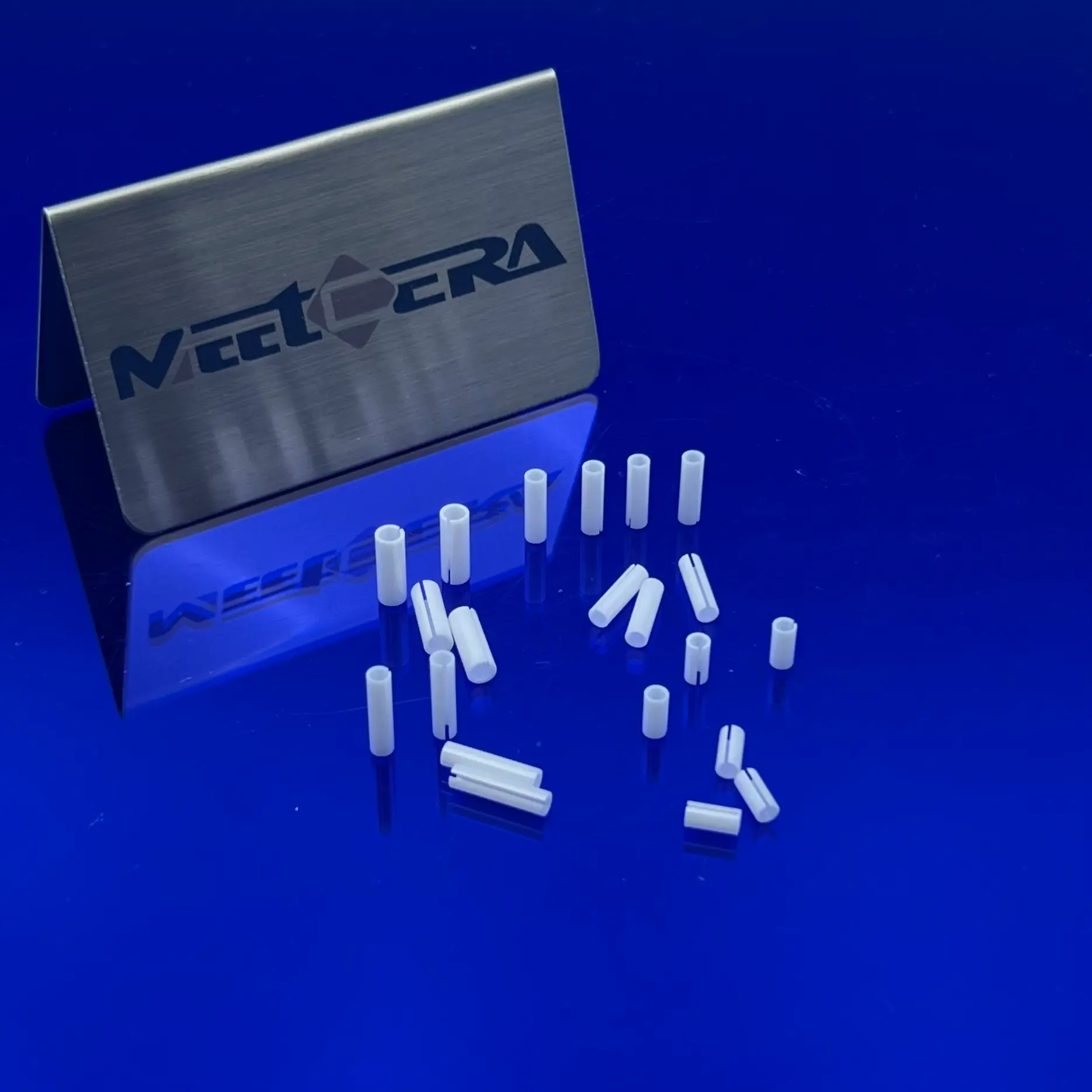

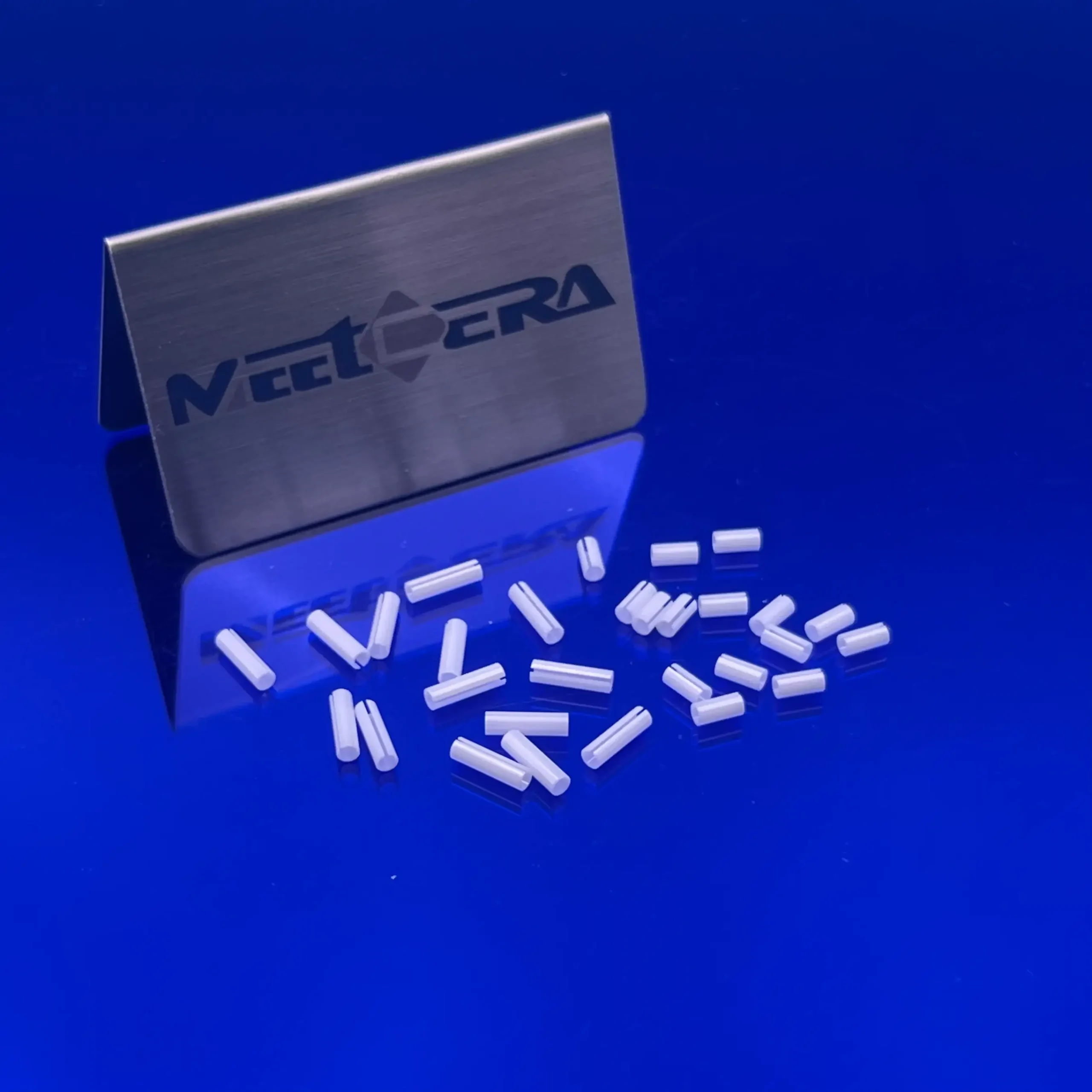

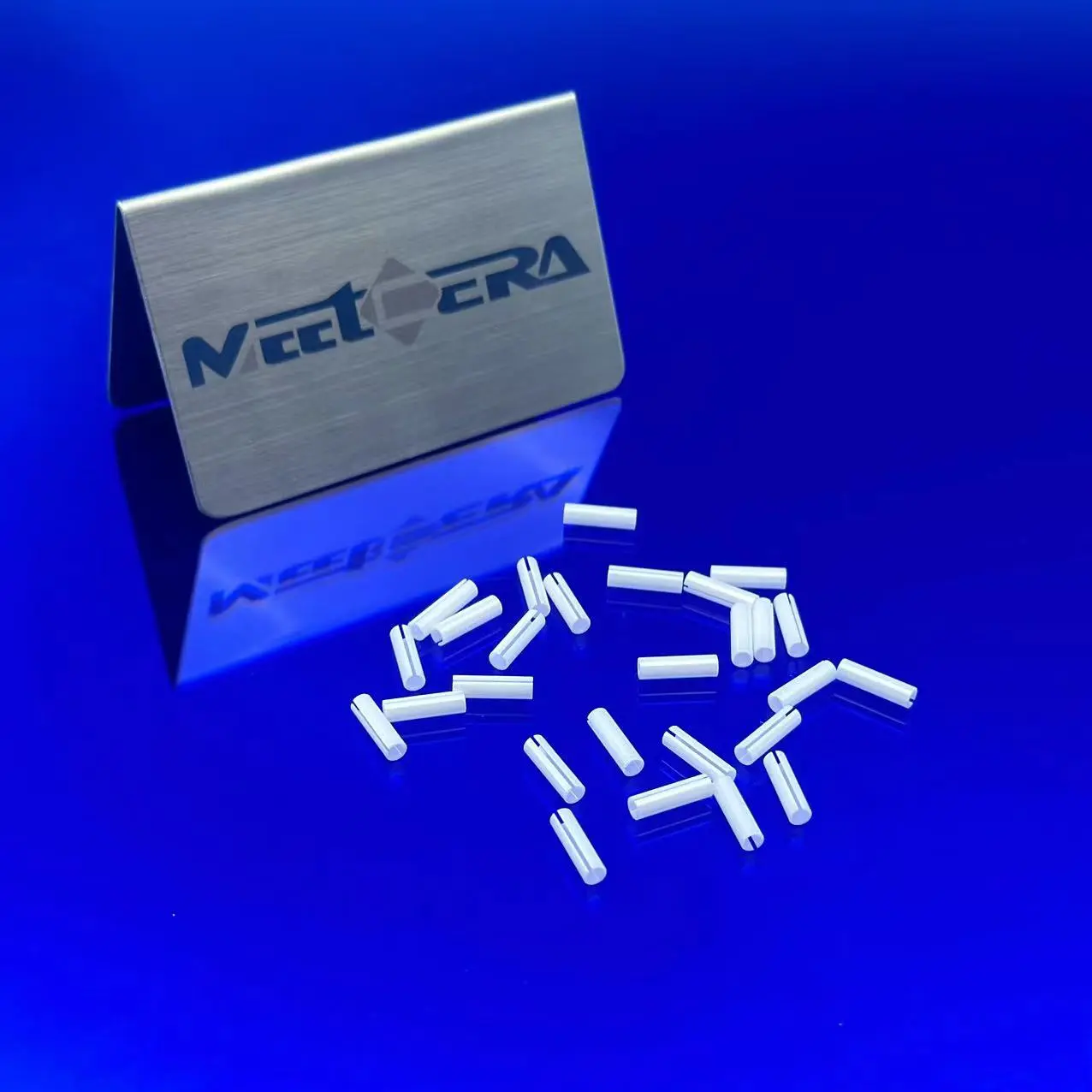

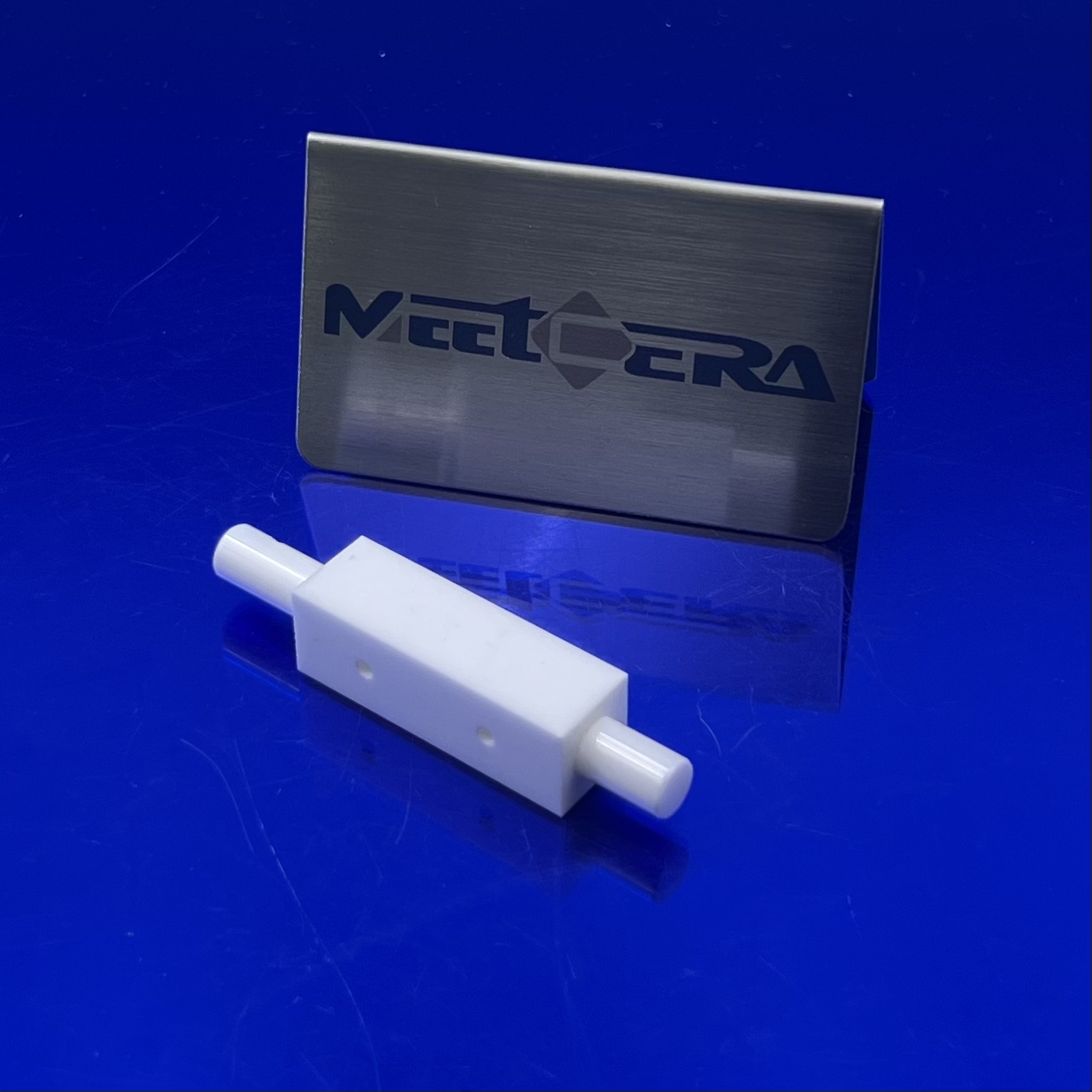

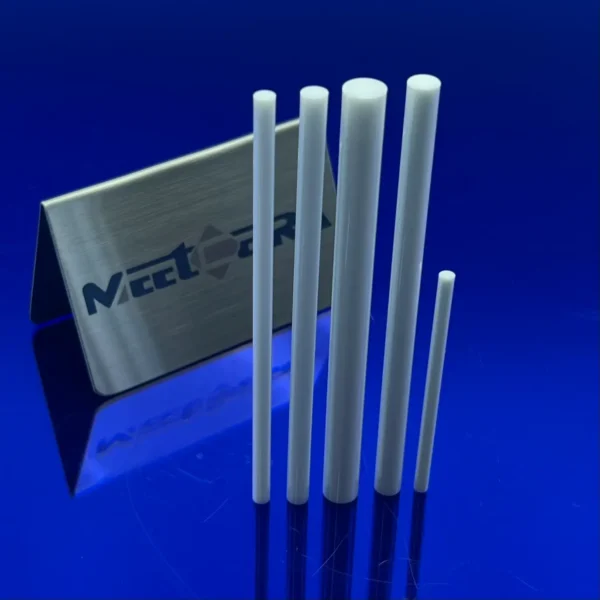

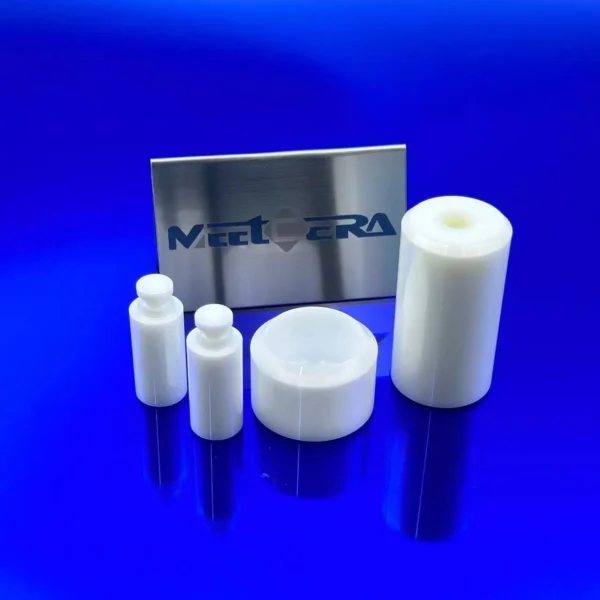

Zirconia Ceramic Thin Small Tube

Zirconia ceramic fine tube (also known as zirconia micro tube, capillary tube, or small-diameter zirconia tube) is a high-precision advanced ceramic component made from high-purity yttria-stabilized zirconia (Y-TZP / YSZ). It features ultra-fine dimensions, exceptional toughness, and superior performance in extreme environments. Manufactured using cold isostatic pressing, high-temperature sintering, and precision fine polishing (inner/outer bore), it is ideal for applications requiring micro-scale accuracy, high wear resistance, and chemical/thermal stability.

Key Features:

- Superior toughness & strength: Fracture toughness ≥8–10 MPa·m¹/², flexural strength ≥1000 MPa — highly resistant to cracking in thin-wall structures

- Excellent wear & abrasion resistance :Hardness HRA ≥88, inner surface ultra-smooth after fine polishing, far outperforms alumina or metal capillaries

- Outstanding corrosion & chemical resistance: Inert to strong acids, alkalis, molten metals, and most aggressive media

- High temperature & thermal shock resistance: Max service temperature up to 2200°C+, low thermal expansion, excellent thermal stability for rapid cycles

Main Application Areas:

- Precision Fluid & Gas Control: Micro nozzles, capillary for precise fluid dispensing, chromatography, medical dosing pumps

- Medical & Analytical Instruments: Thermocouple protection sheaths, micro sampling tubes, dental/medical precision channels, lab-on-chip components

- Electronics & Sensors: Insulating micro-tubes, oxygen sensor housings, high-voltage feedthroughs, fiber optic alignment sleeves

- High-Temp & Research: Furnace thermocouple tubes, micro-reactor liners, plasma & laser equipment guide tubes

Frequently Asked Questions

Q1: How does zirconia fine tube compare to alumina or glass capillary tubes?

A: Zirconia provides 3–5× higher fracture toughness and far better impact/thermal shock resistance than alumina; much higher durability than glass. Ideal when brittleness or chemical attack is a concern, though at higher cost and density.

Q2: What are the smallest sizes and tightest tolerances available?

A: We offer OD as small as 0.5 mm, ID down to ~0.3 mm with wall thickness 0.1 mm+. Standard tolerance ±0.01 mm.Ultra-fine/long specs — please confirm feasibility based on aspect ratio.

If you need exact dimensions (OD/ID/length), surface finish (mirror polish ID/OD), special tolerances, batch quantity, or samples, please provide details — we offer fast customization and technical support!