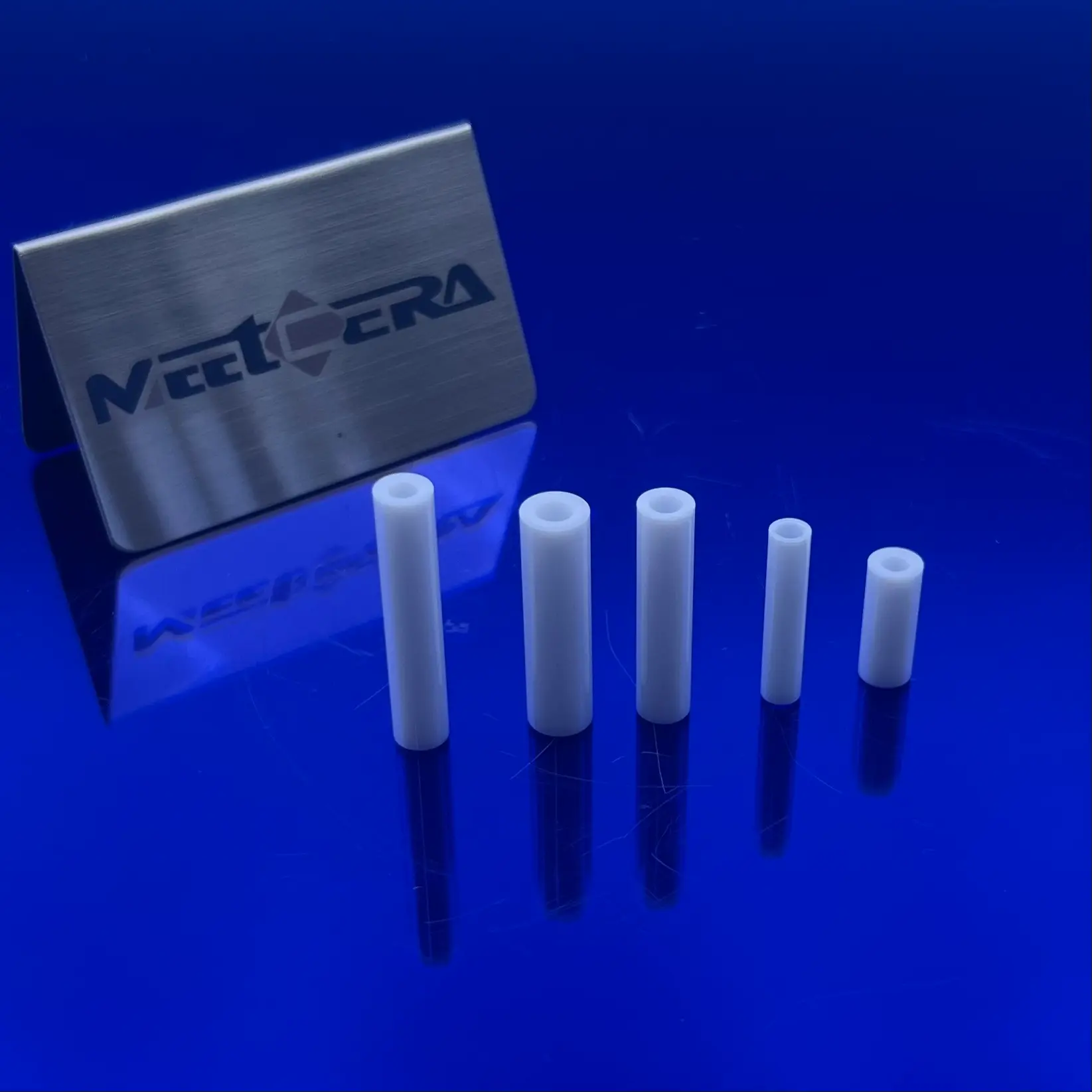

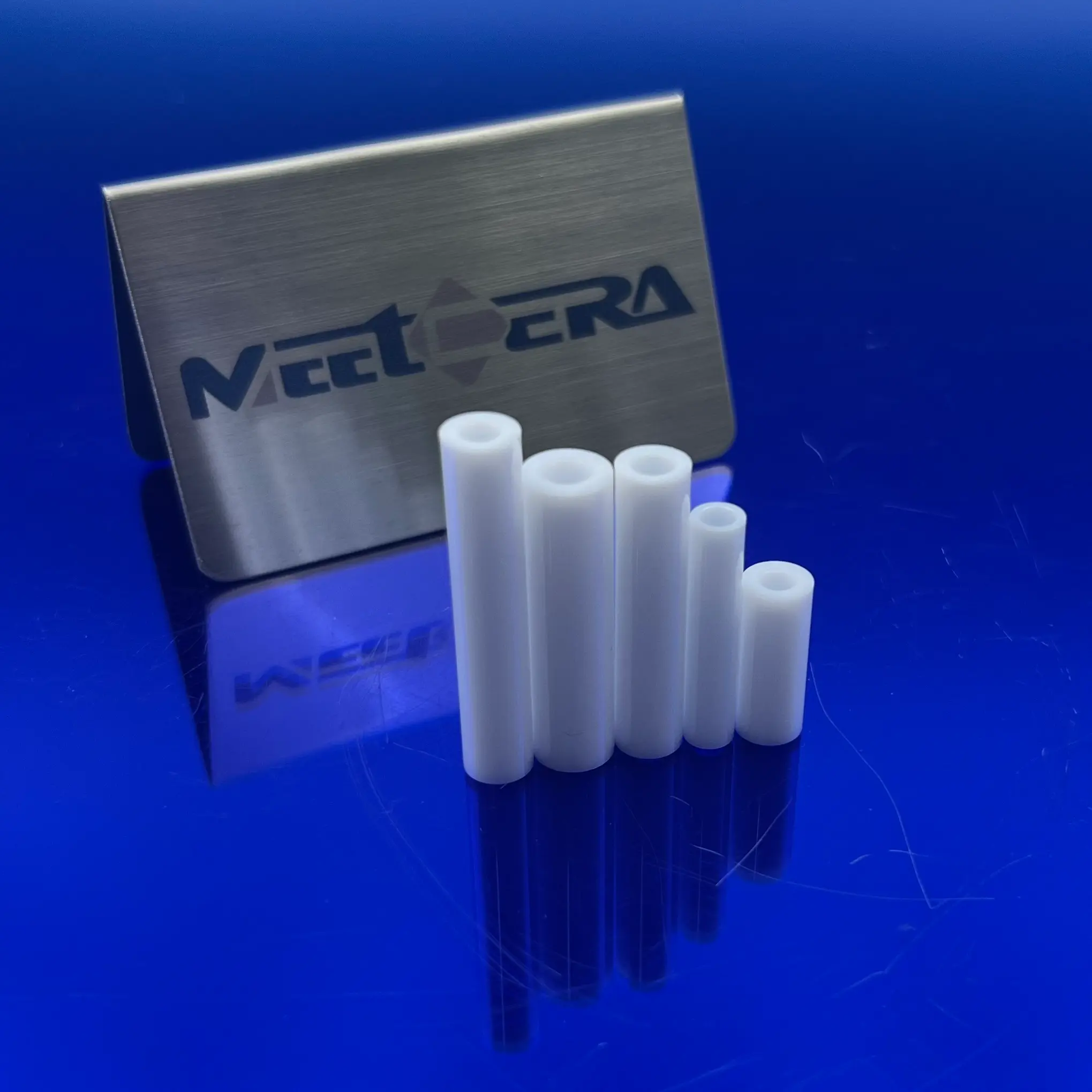

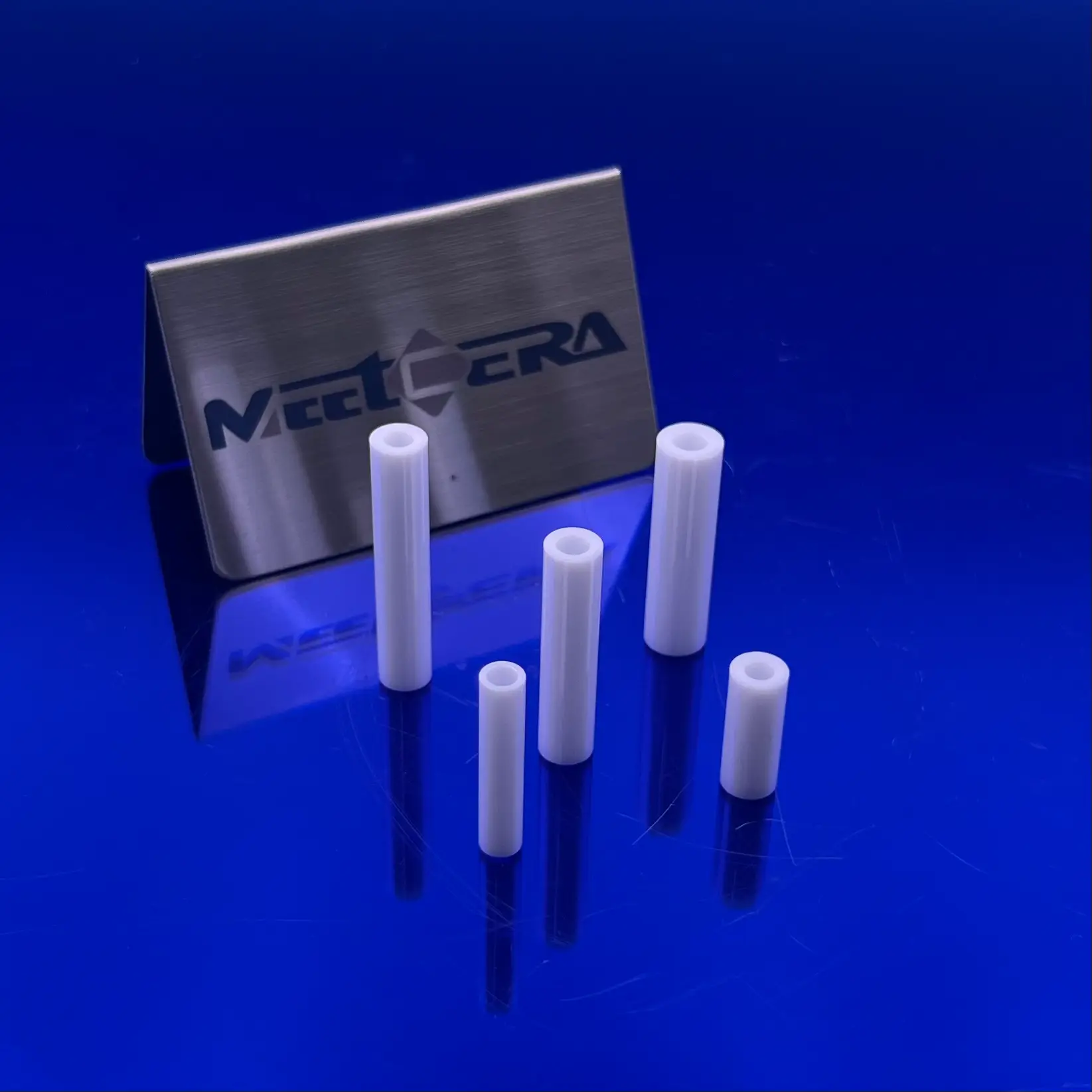

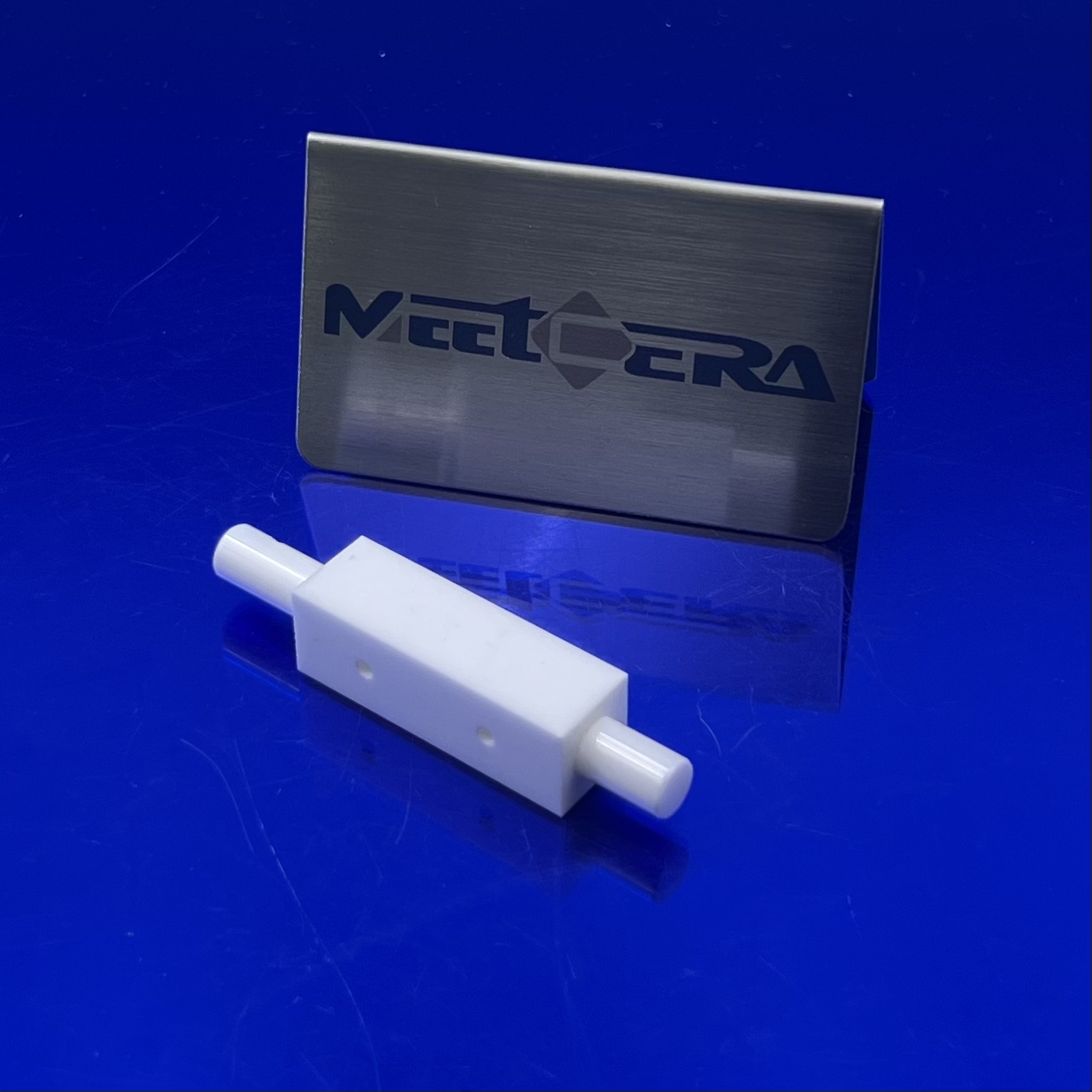

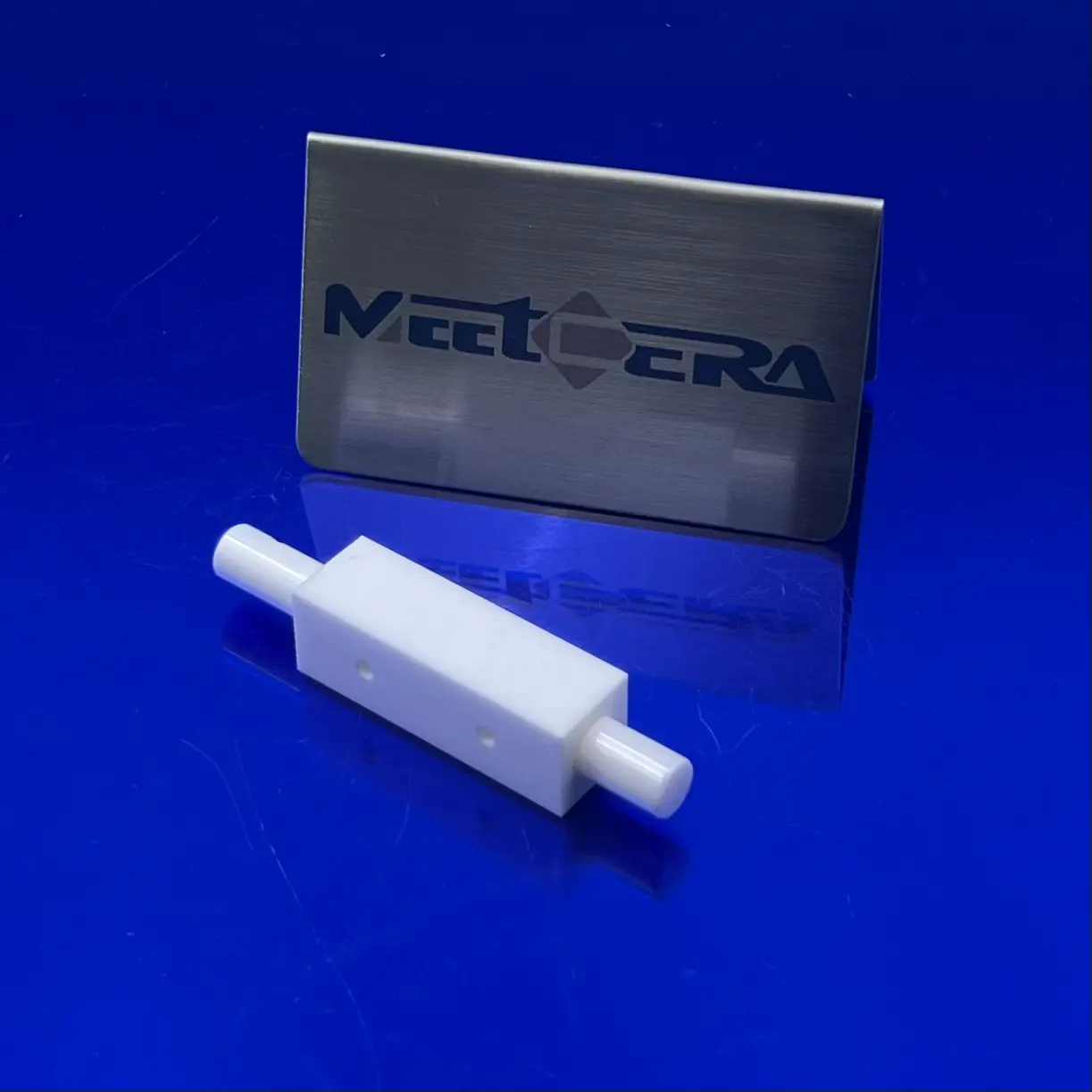

Zirconia Ceramic Tube

Made from high-purity zirconia (ZrO₂ ≥ 94.5%–99.9%) stabilized with 3–8 mol% yttria (Y-TZP structure), this ceramic tube combines exceptional fracture toughness, hardness, high-temperature resistance, and excellent corrosion & wear resistance. It is widely regarded as the “ceramic steel” and is ideal for extreme-condition protection and fluid/structural applications.

Key Advantages:

- Highest fracture toughness among structural ceramics: 8–10 MPa·m¹/² (2–3× that of alumina ceramics)

- Hardness HV 1200–1400, close to gemstone level

- Maximum service temperature up to 1600–2200°C

- Outstanding resistance to abrasion, strong acids/alkalis, and molten metals

Main Application Scenarios:

- High-Temperature Thermocouple / Furnace Tube Protection:Thermocouple protection sheaths and internal structural components in single-crystal silicon, polycrystalline silicon growth furnaces, semiconductor diffusion furnaces, and vacuum high-temperature furnaces.

- Chemical Corrosion-Resistant Transfer: Precision piping and valve linings for strong acids, strong alkalis, high-temperature molten salts, and corrosive slurries in chemical and petrochemical industries.

- Solid Oxide Fuel Cell (SOFC) and Oxygen Sensor Components: High-temperature gas channels, oxygen-ion conducting parts, and sensor protection tubes.

- Industrial Wear-Resistant Guide Tubes: High-wear guide wires/yarn guides in textile, papermaking, and printing industries, as well as powder and granular material transfer tubes.

Frequently Asked Questions(FAQ)

Q1: What are the main advantages of zirconia ceramic tubes compared to alumina ceramic tubes?

A: Zirconia ceramic tubes offer 2–3 times higher fracture toughness than alumina, providing far superior resistance to impact, chipping, vibration, and thermal shock. They also exhibit better wear resistance and chemical corrosion resistance, making them ideal for demanding environments.

Q2: Can the tube really withstand up to 2200°C? What should I pay attention to?

A: Certain high-purity, fully stabilized zirconia formulations can withstand 2200°C for short periods in inert or reducing atmospheres. For continuous long-term use, we recommend staying within 1600–1800°C (depending on stabilizer content and actual conditions). Prolonged exposure to oxidizing atmospheres at very high temperatures may cause phase transformation—please consult us about your specific operating environment.

Request a Quote or Sample: Please provide outer diameter / inner diameter / length, polishing requirements, operating environment, or drawings. We will respond quickly with accurate pricing and sample solutions!