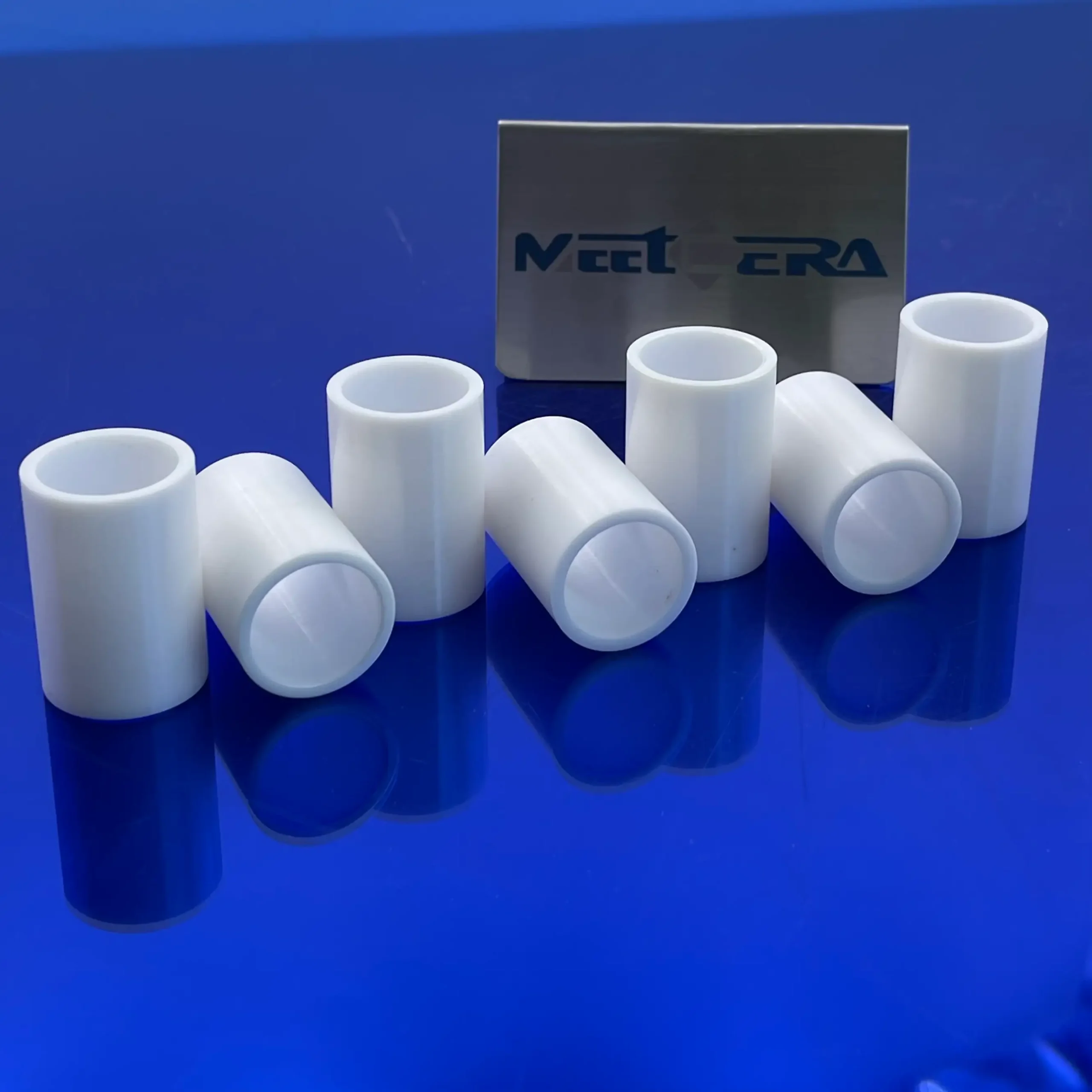

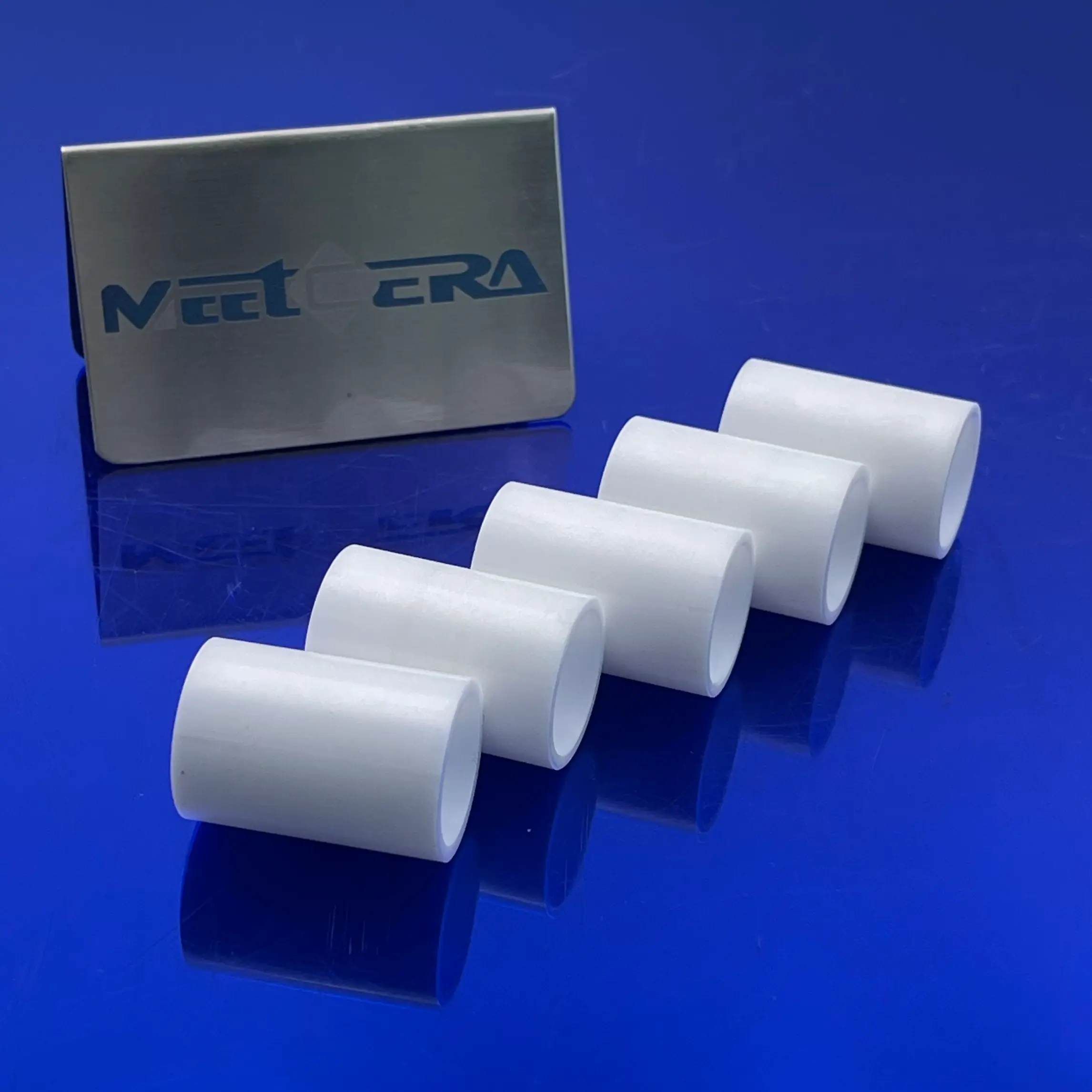

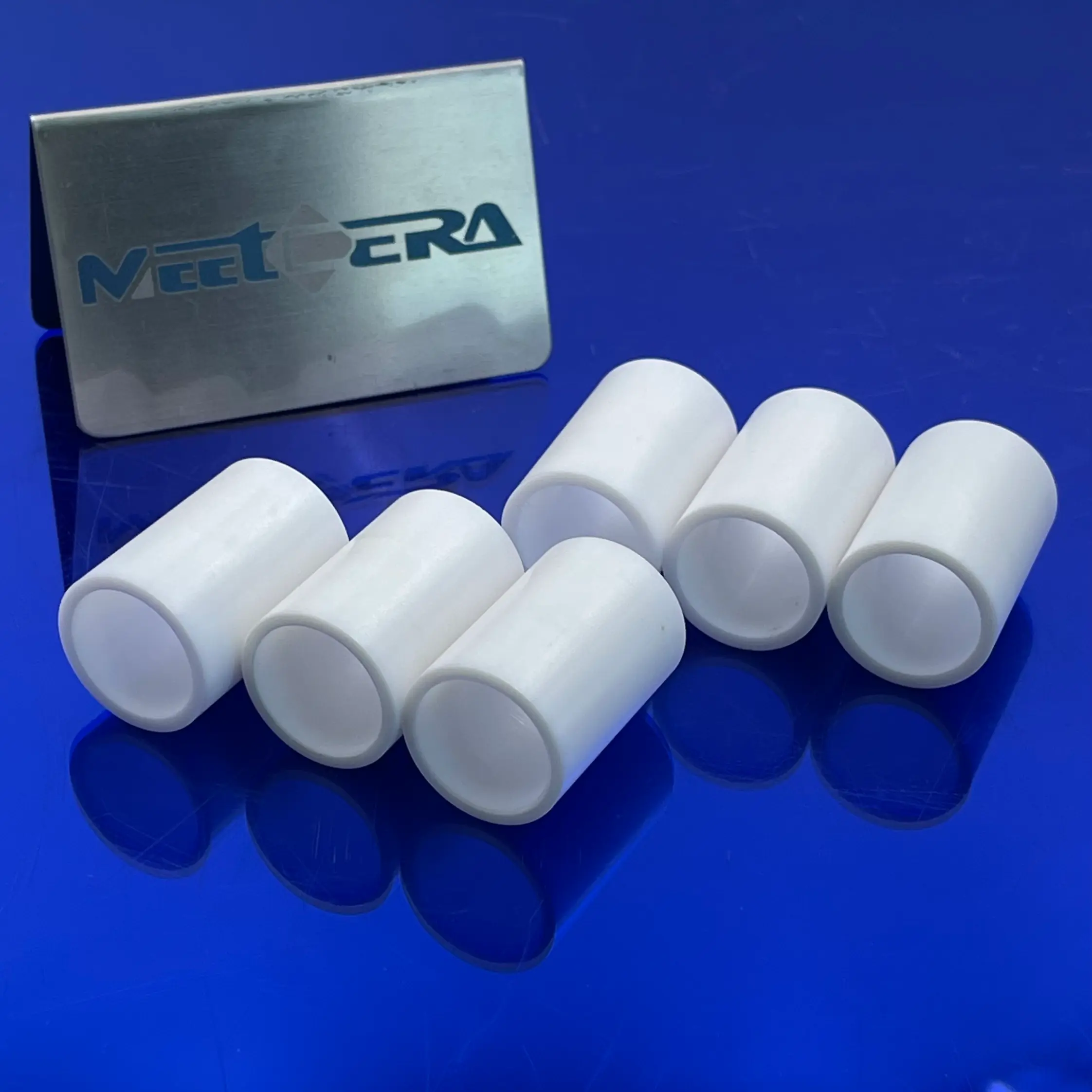

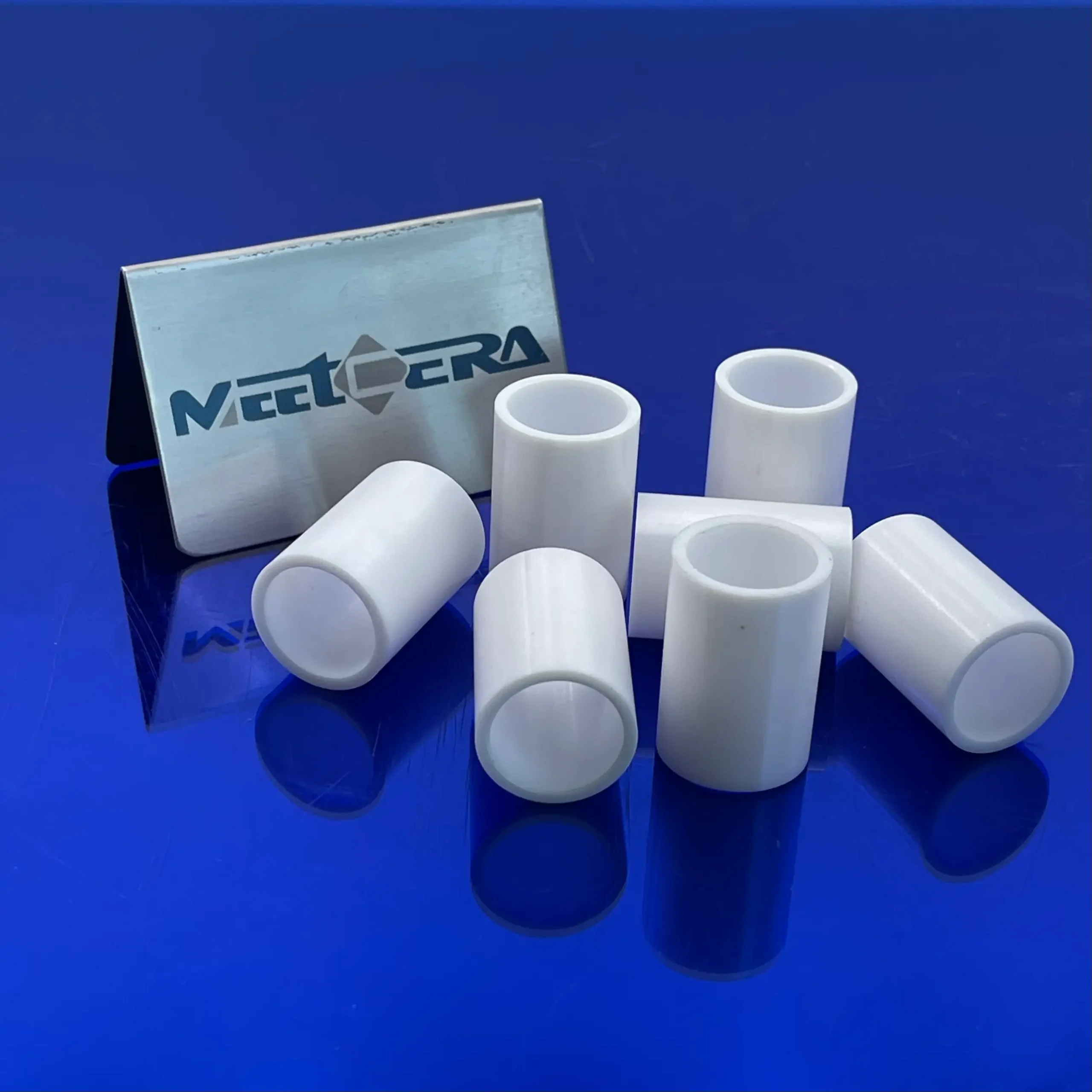

High-Performance Zirconia Ceramic Tube

Manufactured from premium yttria-stabilized zirconia (YSZ, ZrO₂ ≥ 99.5%) using advanced isostatic pressing, high-temperature sintering, and precision machining, Meetcera zirconia ceramic tubes deliver superior thermal stability, mechanical reliability, and contamination-free performance in extreme conditions.

Key Performance Highlights:

- Extreme high-temperature capability: Long-term use up to 1900–2000°C in air; 2100–2200°C in vacuum/inert atmospheres

- Outstanding fracture toughness & strength: Transformation toughening mechanism provides superior impact resistance compared to alumina

- Superior chemical & corrosion resistance: Inert to acids, alkalis, molten metals, and aggressive slags — minimal contamination

- Low thermal conductivity & excellent dimensional stability: Low expansion coefficient ensures reliability under thermal cycling

Typical Application Scenarios:

- Thermocouple protection sheaths and furnace tubes in high-temperature kilns, semiconductor diffusion, and polysilicon ingot furnaces

- Insulation and structural components in solid oxide fuel cells (SOFC) and oxygen sensors

- Precision liners, bushings, and fluid-handling tubes in chemical processing, petrochemical, and abrasive slurry environments

- High-temperature refractory supports, thermal barrier elements, and aerospace/automotive components

FAQ

Q1: Why zirconia tubes over alumina?

A: Higher max temperature (>2000°C), better toughness & impact resistance, superior chemical inertness, longer life in harsh conditions.

Q2: Key usage precautions?

A: Avoid thermal shock (ramp ≤5°C/min above 800°C); handle carefully to prevent chipping; use in controlled atmospheres for peak performance.